Reduce your carbon footprint with eco-designed equipment and shrink-sleeve labels

- Reduce your carbon footprint with eco-designed shrink-sleeves, such as LWPET®, 50% thinner

- Flexible equipment that adapts to regulatory constraints and constant market changes.

- Energy consumption mastery to reinforce the reduction of your carbon footprint

- Optimized TCO, from the supply chain to the maintenance of your equipment

Features

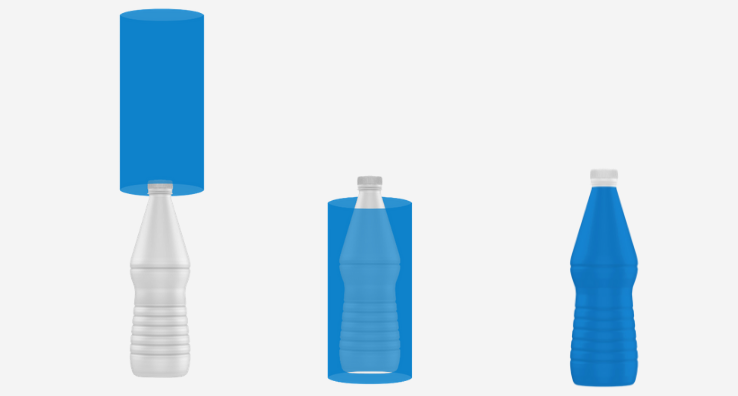

Reduce the carbon footprint of your packaging with new generation films

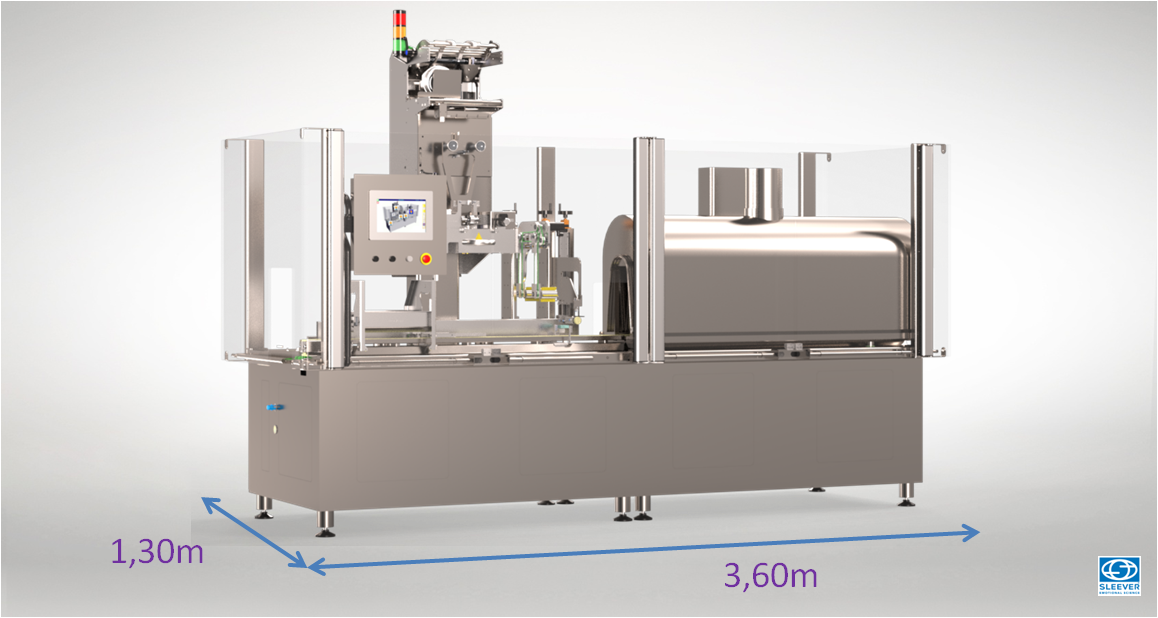

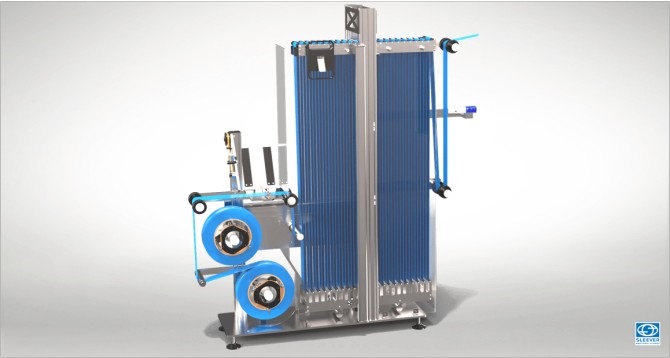

This compact, one-piece, all stainless steel machine is suitable for the food, dairy, personal care and household markets.

Equipped with a servo-drive technology that allows fine and precise adjustments, it is adapted to new generation films with reduced thickness, from 40 to 20 microns such as LWPET®, to contribute to the reduction of the carbon footprint. Thus, the high-capacity remote unwind unit is specifically designed to handle thin films.

Industrial agility to comply with your brands expectations

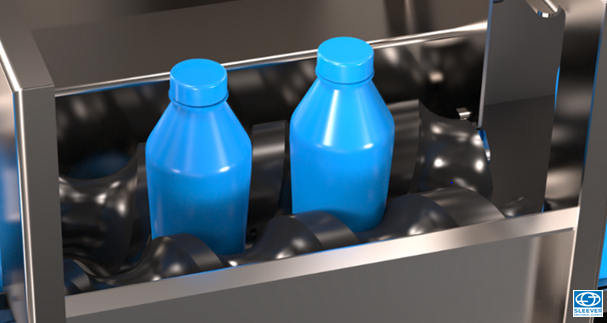

This technology meets the growing need for flexibility in the markets, by allowing the processing of packaging made of different materials (HDPE, PE, PP...), full or empty, in dry or wet condition, in line or off line.

The agility is reinforced by tools configurable in height and diameter, by format.

Energy consumption optimized to reinforce the reduction of carbon footprint

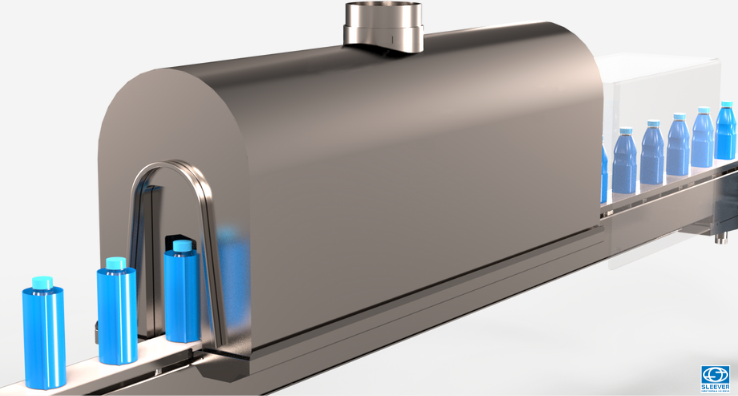

The shrinking tunnel is designed to optimize energy consumption and thus reinforce the reduction of your carbon footprint:

- It has double walls, for excellent thermal insulation

- The chamber is adjustable in height, to optimize the necessary steam volume

- The steam control system allows to adjust the settings to the formats and to recycle the excess of steam

Optimize costs without compromising efficiency

The use of thin films on this eco-designed equipment offers you an optimized operation, without compromising on efficiency:

- more shrink-sleeves on each reel, thus more autonomy in production, and less interventions.

- an increased production capacity while keeping an equivalent storage area and transport capacity

- reduced maintenance to a strict minimum thanks to a machine technology with very few wearing parts

Options

High reliability at high speed

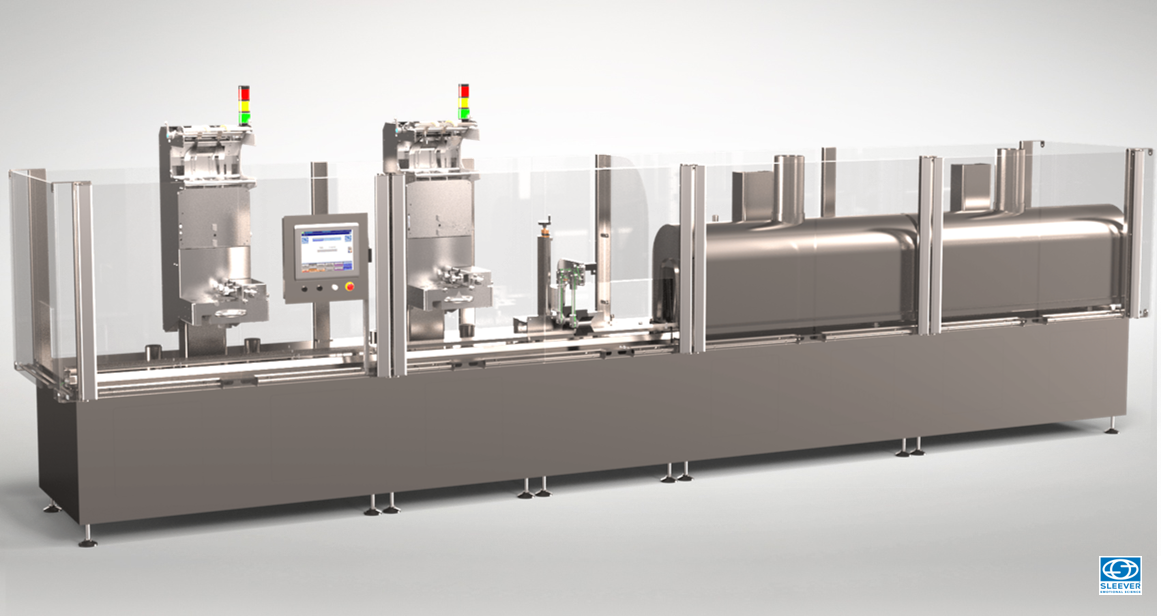

The monobloc design allows the integration of all the necessary modules such as a double application head or a double shrinking tunnel, to meet the constraints of high production rates.

The servo-driven technology and the servo-control associated with the automatism allow to answer these specifications. The unwinder unit is located outside the machine so as not to disturb the efficiency of the process.

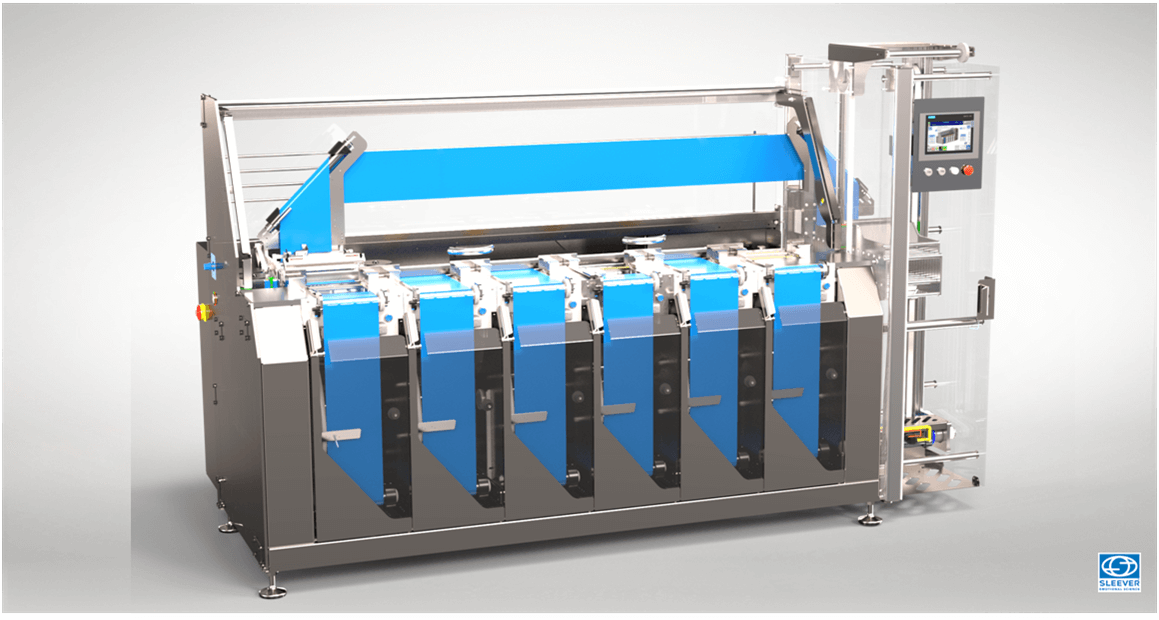

Increase your autonomy for greater productivity

The 6-reel automatic shrink-sleeve unwinder unit increases production time with no operator intervention. This time gives you the freedom of action to carry out other tasks and improve productivity.

The performance of your line combined with an efficient control module

A machine designed for HDPE, PE,or PP containers, equipped with a quality control system that detects specified defects that may occur during production. The non-conforming products are scanned, controlled and rejected via different systems (chute, ejection table or exit conveyor), according to specifications. This ensures performance and guarantees the expected level of quality.

The guarantee of a dry product for the packaging at the end of the line

A watertight structure with a stainless steel frame to withstand humid working conditions, the equipment can be combined with dryers at the entrance and exit of the line to minimize the presence of traces of moisture on the products to be sleeved. This means taking into account the large temperature differences between the filling and sleeving phases.

Specifications

Machines

| Conveyor height | 980 mm +/- 50mm |

| Speed | 500 bpm |

| Cutting diameter | 100 mm |

| Steam consumption | 150 Kg/h |

| Steam pressure | 6 - 8 bars |

| Electrical consumption | 12 kW/h |

| Machine length | 3600 mm |

Packagings

| Materials | HDPE, PP, PE |

| Shapes | Cylindrical, square, special |

| Sizes | 20 ml - 1l |

| Products diameter | 35 - 95 mm |

| Products height | 90 - 300 mm |

Sleeves

| Functionalities | Full body |

| Type of films | PET, RPET,... |

| Films thickness | 20 - 50 microns |