Sleever Group

As the innovative driver of the shrink-sleeve technology, our company is a Family Company, made by men and for men.

50 years of expertise, passion and innovation serving brands that drive us, guided by the alliance of science and emotion: science fuels emotion, emotion guides science.

AN INTERNATIONAL GROUP THAT CARES ABOUT ITS CUSTOMERS

Expert and committed teams serving markets and clients

Our 1,000 expert employees of 25 nationalities serve our clients and are dedicated to meeting our commitments on a daily basis. Present worldwide, our international footprint is combined with the human values of a Family Company.

An international presence that combines global vision and client proximity

Our 14 industrial sites on 5 continents (Europe, Africa, Asia, North America, South America), offer a global vision combined with a local presence in order to accompany our clients on diversified markets. We are proud to be the partner of their product launches in over 50 countries.

Innovation, the driving force behind our development

Teams of multi-skilled engineers and technicians work together to find packaging and labeling solutions to meet the needs of consumer product industries.

Our multidisciplinary R&D teams have allowed us to build an extensive offer: our trademarks and patents (more than 500) clearly demonstrate this.

A UNIQUE INTEGRATION OF THE SHRINK-SLEEVE TECHNOLOGY

Being the innovative pioneer of the shrink-sleeve technology, we master the entire value chain: from film formulation, printing, converting, capital goods manufacturing to services.

Formulation and manufacture of heat-shrinkable films

Formulation and manufacture of heat-shrinkable films

Graphic and pre-press expertise

Graphic and pre-press expertise

Sleeve printing and transformation

Sleeve printing and transformation

Design and production of capital goods

Design and production of capital goods

Contract and local services

Contract and local services

Formulation and manufacture of heat-shrinkable films

Formulation and manufacture of heat-shrinkable films

Graphic and pre-press expertise

Graphic and pre-press expertise

Sleeve printing and transformation

Sleeve printing and transformation

Design and production of capital goods

Design and production of capital goods

Contract and local services

Contract and local services

At the heart of vertical process integration: the mastery of films

This is an invaluable expertise that we have been offering our clients for 45 years: 60 exclusive formulas that are constantly being redesigned to support brands in their quest for excellence and, now more than ever, in their efforts to ensure an ecological and carbon-neutral transition.

For over 10 years, we have been working with all the stakeholders in the packaging recycling and recovery sector in the United States and Europe to provide consumers with a responsible and sustainable offer.

Our products are APR and EPBP certified.

Pre-press graphic expertise for your graphic designs

Studio Sleever, with a presence on 5 continents (Paris, Toronto, Sao Paulo, Shanghai, Baden-Baden), offers integrated pre-press graphic expertise and 3D morphing capabilities to assist you in the design of your creations, and in their implementation on your products. Our teams use the most advanced technologies:

- Webcenter for dynamic project tracking

- 3D morphing for complex shape management

- Fablabs for product prototyping and qualification

- Color management up to Press Proof

- A multidisciplinary, multilingual and international team dedicated to serving brands

Multiple printing techniques and integrated transformation and finishing steps

Our different sites, with locations on all continents, offer a wide range of printing techniques, which are perfectly adapted to different markets and projects. From rotogravure to digital printing, as well as flexography, offset, and hybrid technologies, we have a wide range of possibilities. Our expertise also includes the conversion and finishing stages to offer our clients products that are ready to be used.

In our quest for excellence, we have been working for many years to achieve carbon neutrality through an ambitious policy and constant client support. Our quality experts, our working methods, 5S, MES, accompany our employees on a daily basis in these processes. ISO 9001 and Ecovadis are two of our standards.

Advanced sleeve technology for expert and specialty equipment

With teams dedicated to R&D and engineering, Sleever Machines Group ensures the design and production of expert and specialty equipment, thanks to a unique mastering of sleeve technology. Clients are supported right up to commissioning and throughout the life cycle of the machine, with a range of expert services for fast and efficient interventions. Our factories in France and Germany, our expert centers, our support services, which are present in the USA, Brazil, Europe and China, make Sleever Machines Group a unique company, with a strong know-how and local expertise.

Customized finishing and services for your projects

Our FabLabs allow you to validate your projects under industrial conditions. We ensure the custom finishing of packaging worldwide (Paris, Reims, Warsaw, Sao Paulo, Toronto, Shanghai) in close proximity to our clients.

We ensure multiple services (conditioning and custom finishing) and boost your communication operations and events, with MySleeve, so you can offer personalized products in a unique way.

VALUES AT THE HEART OF OUR IDENTITY

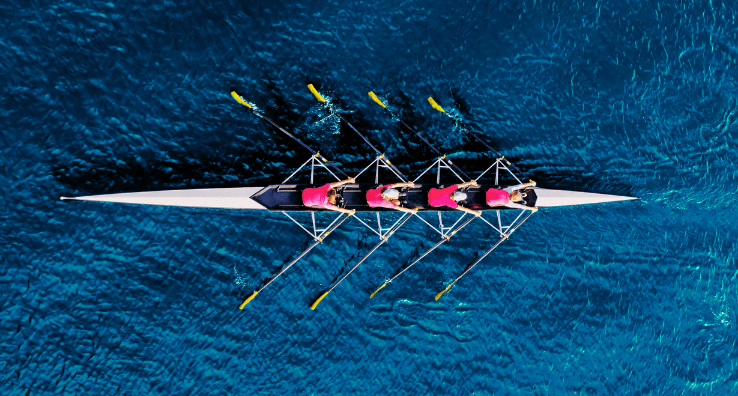

Human values and ethics at every level of the company

We practice humanistic management, with strong human values anchored at every level of the company. We base our relationships on mutual respect, which is the foundation of our corporate ethics that are applied both internally and externally.

Honoring our commitments, the foundation of our identity

The culture of excellence permeates our daily lives and defines our identity. Our teams are committed to offering our clients and partners the best packaging and machine solutions. Delivering the desired quality within the expected timeframe is part of our commitment.

A committed environmental policy

We support our customers in the ecological transition of their products, with eco-design and circular economy solutions. As a committed and civic-minded group, we have integrated our environmental policy into the daily work of our sites and teams.

Ensuring our continuity as a family company on a human scale

The family culture of Sleever, a human-sized company, guarantees a long-term vision and strategy: the objective is to ensure our continuity, in a sustainable growth model, thanks to an investment policy and a permanent innovation model.

THE GROUP'S PURPOSE

Understand market trends and innovate for brands

It is by understanding evolutions, consumer expectations and market trends that we can offer products that innovate and reinforce the identity of brands. We are constantly projecting ourselves into the industry of the future, so that we can offer ever more innovative and high-performance equipment.

Seduce consumers and trigger emotions

In a competitive environment, brands need increasingly attractive products. We design products that will create excitement and reinforce the sensory identity of the products. By triggering emotions, products seduce consumers and create a unique relationship.

VOCATIONS FOR BRANDS

Supporting brands towards an ecological transition while preserving the sensory identity of their products

Eco-design is at the heart of our vocation: with an eco-designed offer for different markets and primary packaging materials, we work with brands to improve recyclability and reduce the carbon footprint of their products, without compromising their sensory identity and integral packaging.

Strengthening and improving the functionality of primary packaging

Capable of covering all materials and shapes, even the most complex ones, sleeves offer an unparalleled design surface to make your products unique with multiple creative effects. This packaging can have either a printed or digital information function and reinforce protection and security. It materializes your communication and promotion operations, in order to boost your sales.

Combining our equipment with the industrial performance objectives of brands

Our expertise and mastery of the value chain allow us to offer expert, specialized or autonomous equipment that is adapted to the diversity of our markets.