Unique late stage differentiation of food jars after sealing

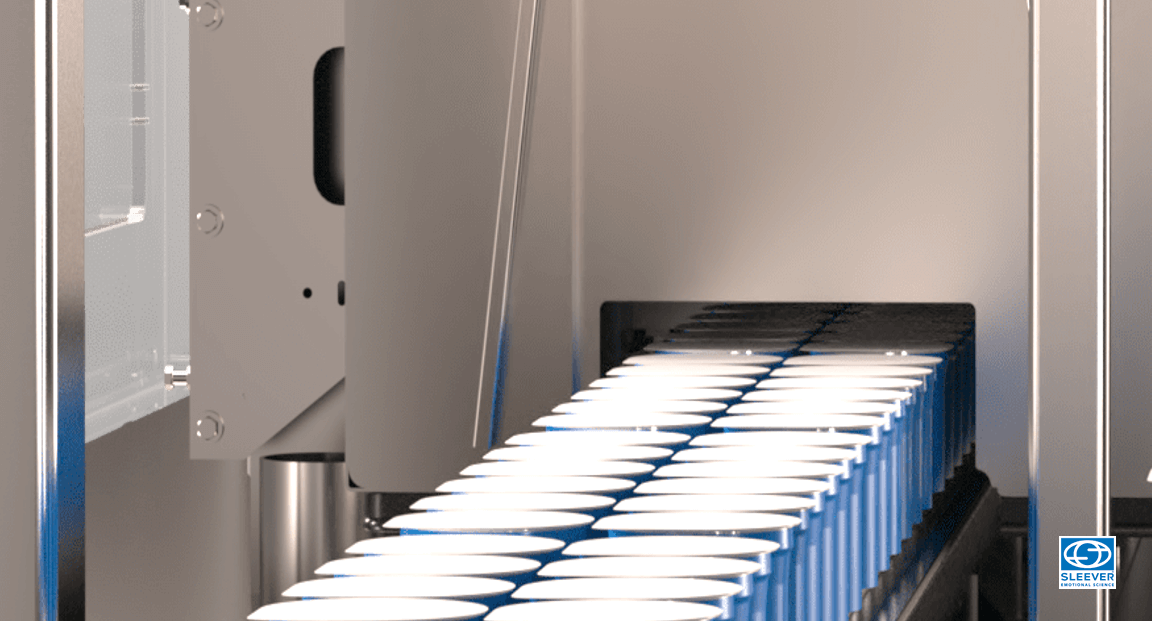

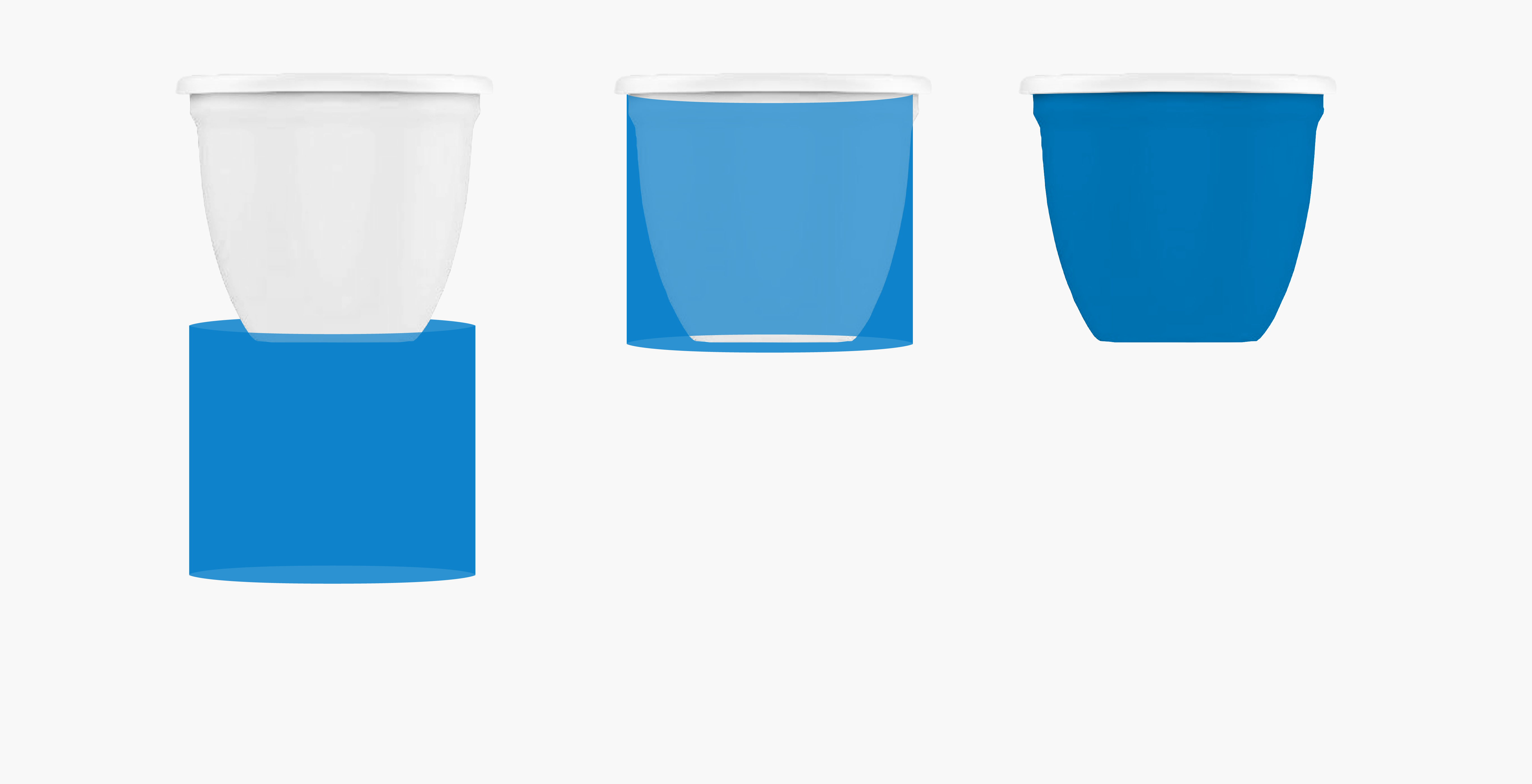

- Bottom-up shrink-sleeve application to avoid contaminating the seal of the product

- Built for medium and high production rates

- Automation serving performance

- Controlled energy for carbon neutrality

Features

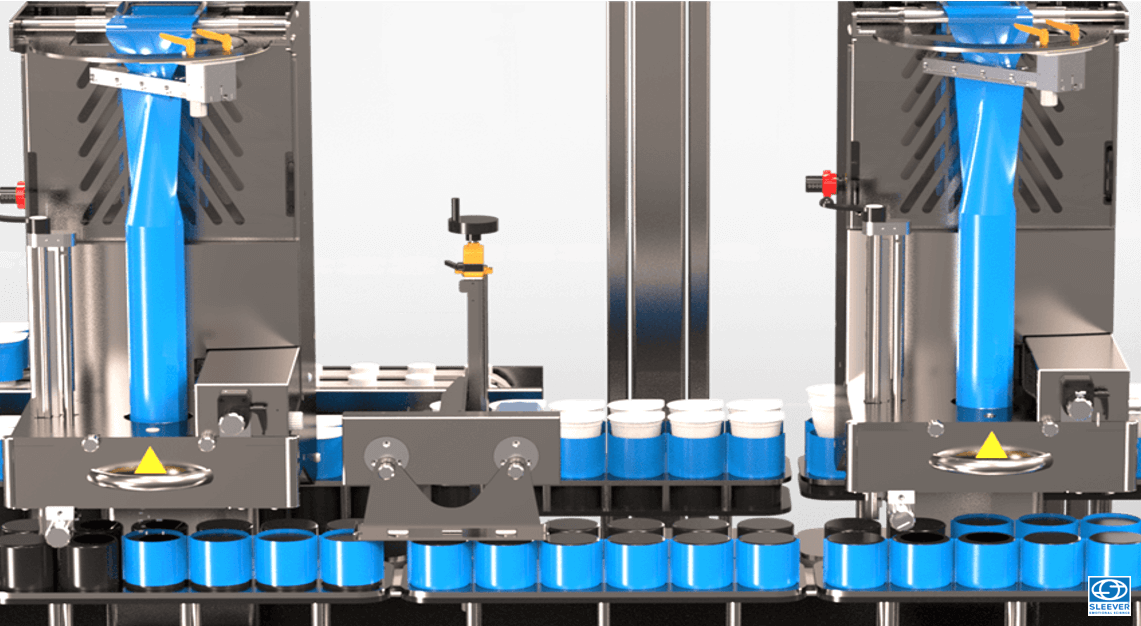

A technology designed for inline application after sealing

A shrink-sleeve application technology that was developed to be integrated into food jar packaging lines (sauces, dairy products, etc.), after filling and sealing, by covering them from the bottom, so as not to contaminate the lid. This allows for a differentiated unique packaging

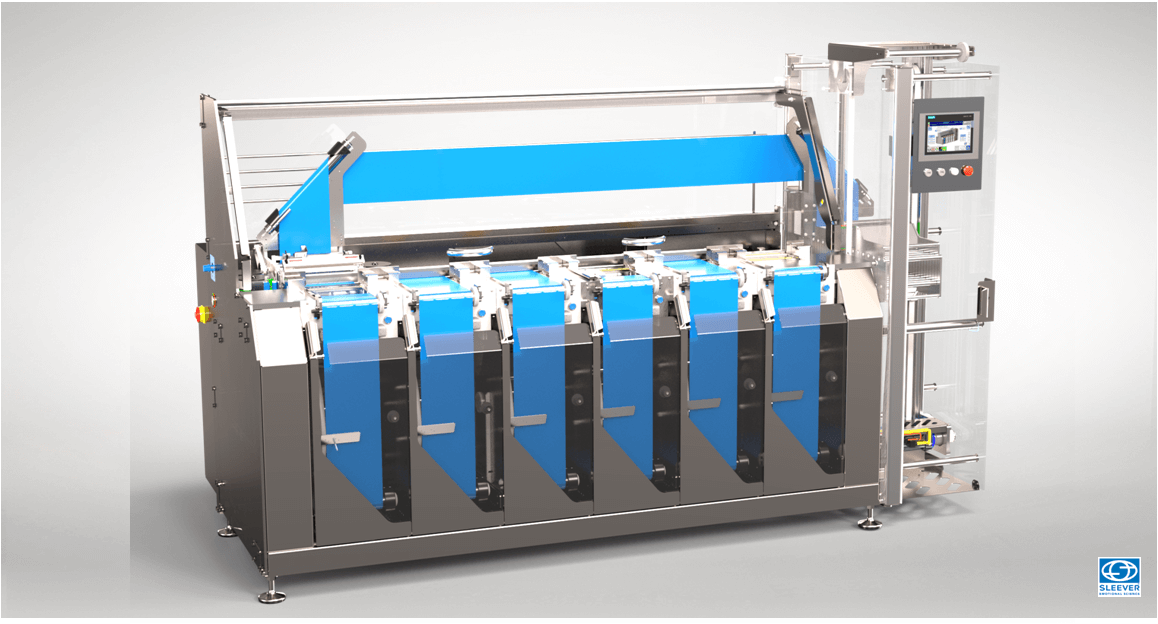

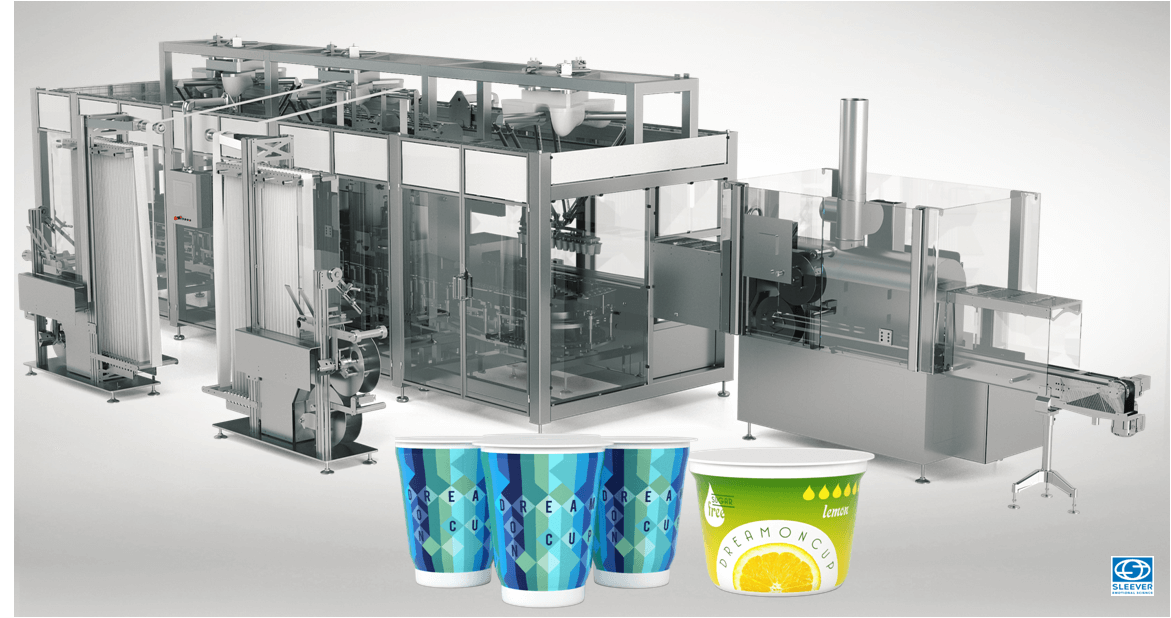

A labelling solution for medium and high production rates

An end of line design with the flexibility to process injected or thermoformed jars, either individual or in multi-packs, allowing for the late stage differentiation of food jars, regardless of their shape or configuration (from 1X2 to 2X4).

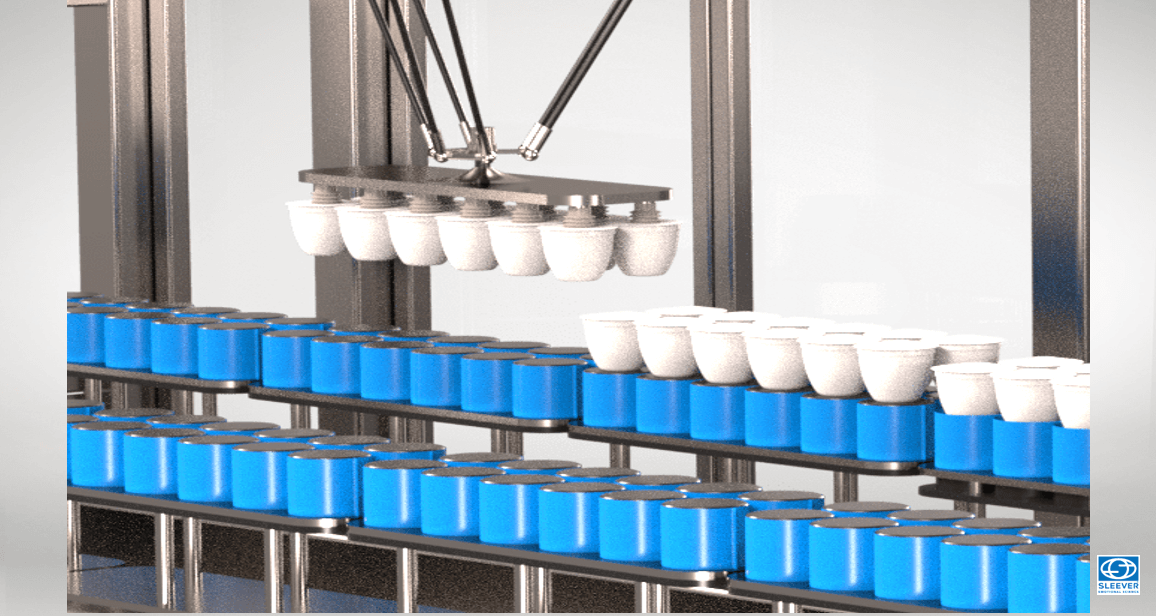

Automation and robots for increased performance

To improve performance, the transfer of the jars to the noria carts during the sleeving and shrinking operations are automated and performed by robots.

A reduced carbon footprint through energy management

This machine is designed to use the latest generation of films,with optimized thickness (20 microns). The shrink tunnel can be adjusted to the height of the jars, and a steam panel allows you to adjust the consumption settings to each format.

Options

Traceability and marking: a response to regulatory specifications

This module is positioned in the magazine for easy control and access. It allows for different forms of coding to meet traceability and serialization requirements: printing of the use-by date, barcode, and other product information. Several printing technologies are available, the most commonly used being inkjet.

Automatic unwind unit for high speed production rates

This machine comes with a multi-reel system and an integrated automatic splicing function. This guarantees "zero machine downtime". It is specially designed for operators who run a line and allows them to increase their autonomy and productivity gains.

Specifications

Machine

| Conveyor height | 980 +/- 50 mm |

| Speed | 200 - 600 cpm |

| Steam consumption | 70 Kg/h |

| Steam pressure | 6 - 8 bars |

| Electrical consumption | 12 kWh |

| Machine length | 8080 mm |

Packaging

| Materials | PET, PS, PP ... |

| Shapes | Cylindrical, oval, square,... |

| Sizes | 60 - 800g |

| Products diameter | 70 - 98 mm |

| Products height | 60 - 150 mm |

| Sizes | 100 gr - 800 gr |

Sleeves

| Functionalities | Full body |

| Type of films | PET |

| Films thickness | 20 to 40 microns |