An eco-designed solution for medical device packaging

Long-term treatments for chronic diseases such as diabetes or asthma are moving from the hospital to the patient's home, with portable devices such as injection pens, inhalers or nasal sprays. For laboratories, the challenge is to be able to reinvent and ensure that the medical device packaging is eco-designed despite being made of multiple parts and materials (container, label, cap..) in order to facilitate the recycling process and increase its sustainability performances.

MEDICAL DEVICE PACKAGING: ECO-DESIGNED SHRINK-SLEEVE LABELS

Smart labels for your medical device packaging recyclability

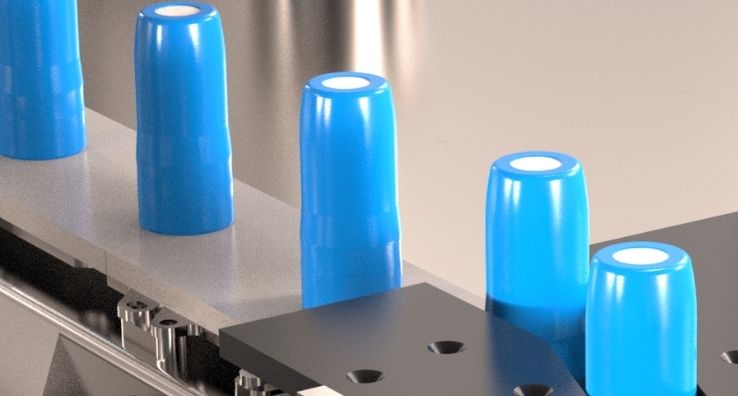

By offering material compatibility, the Medwear® smart label product facilitates the sorting and recyclability of your medical device packaging.

The integral and full-body packaging offered by the shrink-sleeve technology is enriched by specific complementary printing technologies that meet the requirements of the pharmaceutical industry, in terms of font size and Braille printing compliance.

This technology also allows to ensure the traceability required by the industry through the integration of dedicated markers such as serialization, holograms, RFID tags, etc...

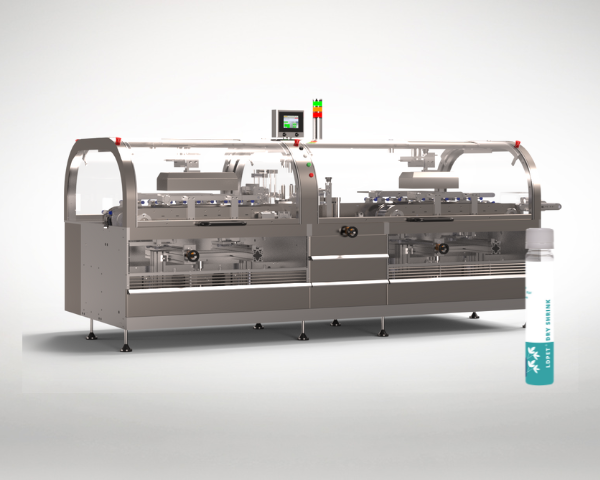

A Machine offer for your medical device packaging

To implement our Medwear® shrink-sleeve labeling solution, we have developed a compact and modular equipment, which meets the pharmaceutical specifications, to dress and label your medical devices in compliance with the regulations and requirements of the industry.

This equipment ensures the traceability required by the industry and integrates a hot air shrink tunnel technology adapted to these products for a qualitative finished product.

Sustainable Multipack Sleeve Packaging

Click on the packaging to discover our offer