Aseptic food products' labelling in a wet environment at high speed

- Suitable for sleeving products on aseptic filling lines in humid conditions

- Frame designed for frequent and aggressive sanitation

- Delivers the desired quality and the expected performance at high speed

- The required autonomy combined with fast format changes

Features

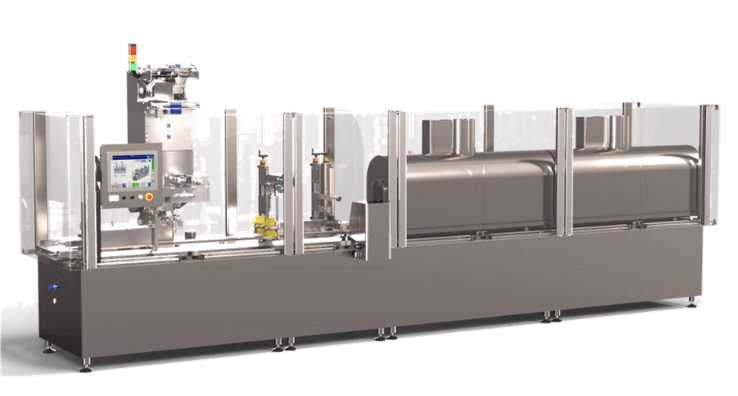

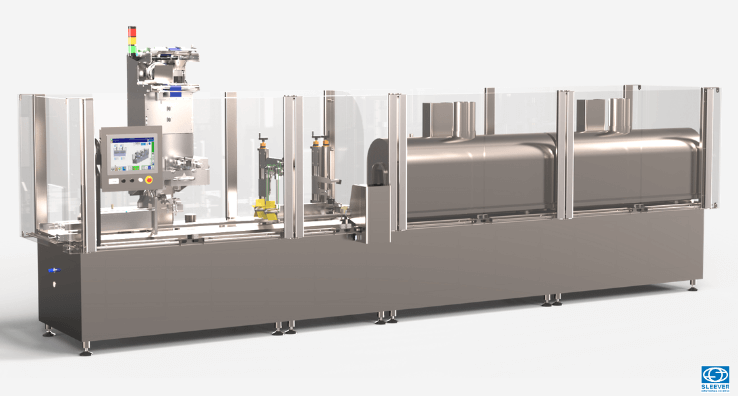

Designed for wet working conditions

A watertight structure with a stainless steel frame to withstand humid working conditions, the equipment can be combined with dryers at the entrance and exit of the line to minimize the presence of traces of moisture on the products to be sleeved. This means taking into account the large temperature differences between the filling and sleeving phases.

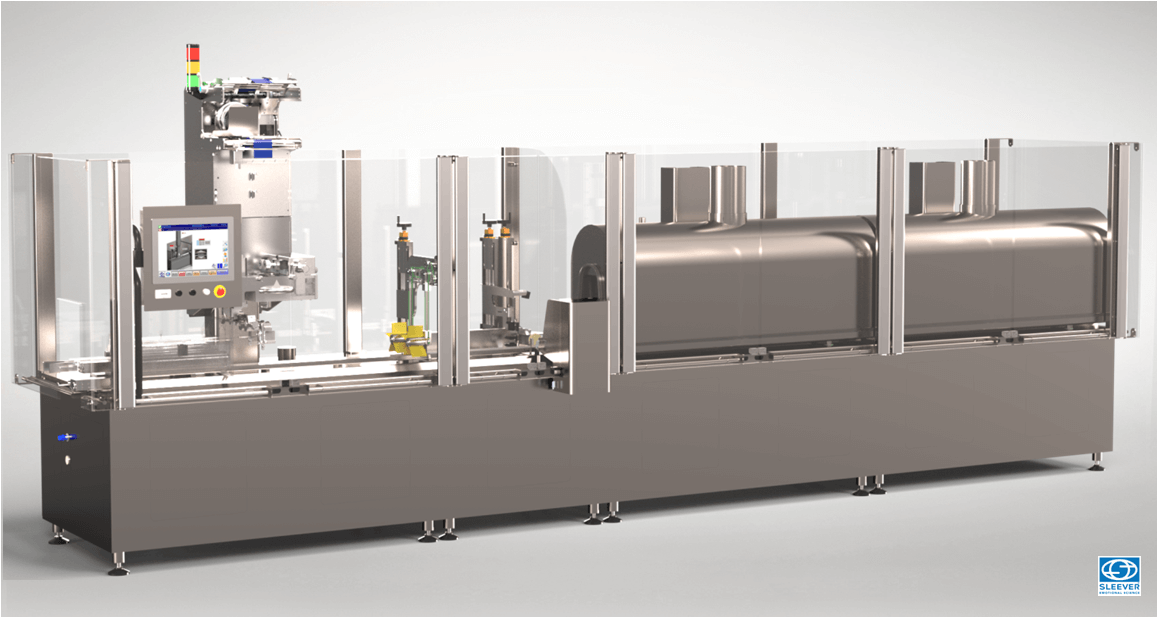

A machine adapted to fresh products that require a high level of sanitation

This robust machine, which complies with manufacturing standards and sanitary regulations for fresh products, is suitable for frequent and aggressive cleaning. The machine is characterized by total transparency thanks to large doors that give access to all the accessible surfaces: the scrolling plane without any retention zone, frame, applicator head and shrink tunnel. The lifting and lowering system provides full access to ensure complete sanitation of the entire machine.

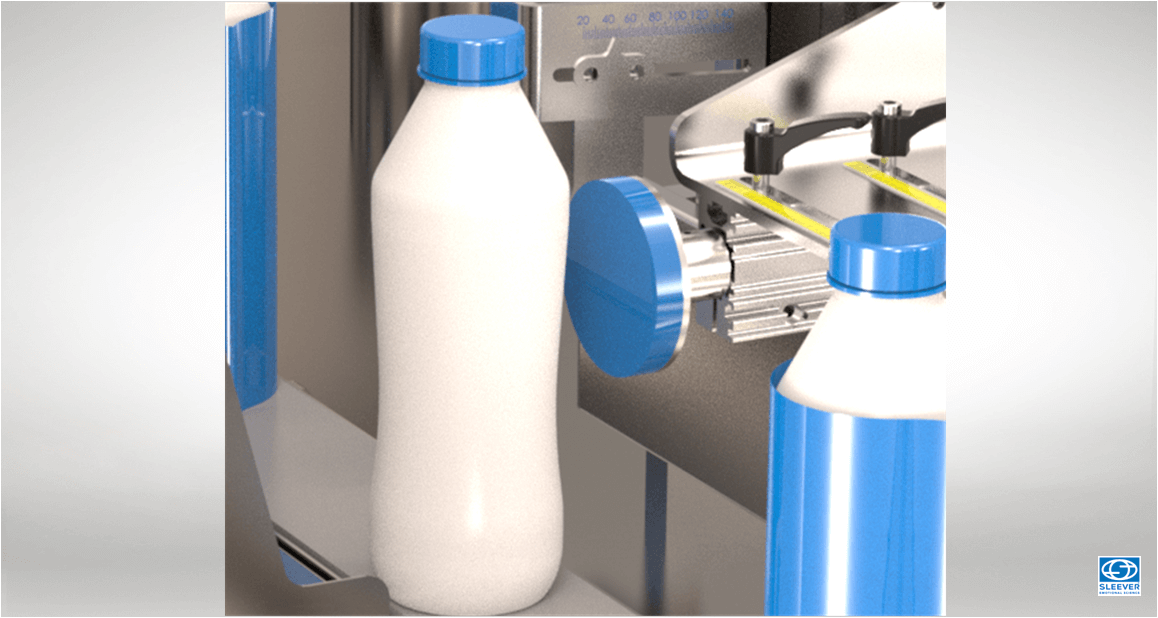

The performance of your line combined with an efficient control module

A machine designed for high outputs of up to 24,000 bottles per hour, for PET or HDPE containers, equipped with a quality control system that detects specified defects that may occur during production. The non-conforming products are scanned, controlled and rejected via different systems (chute, ejection table or exit conveyor), according to specifications. This ensures performance and guarantees the expected level of quality.

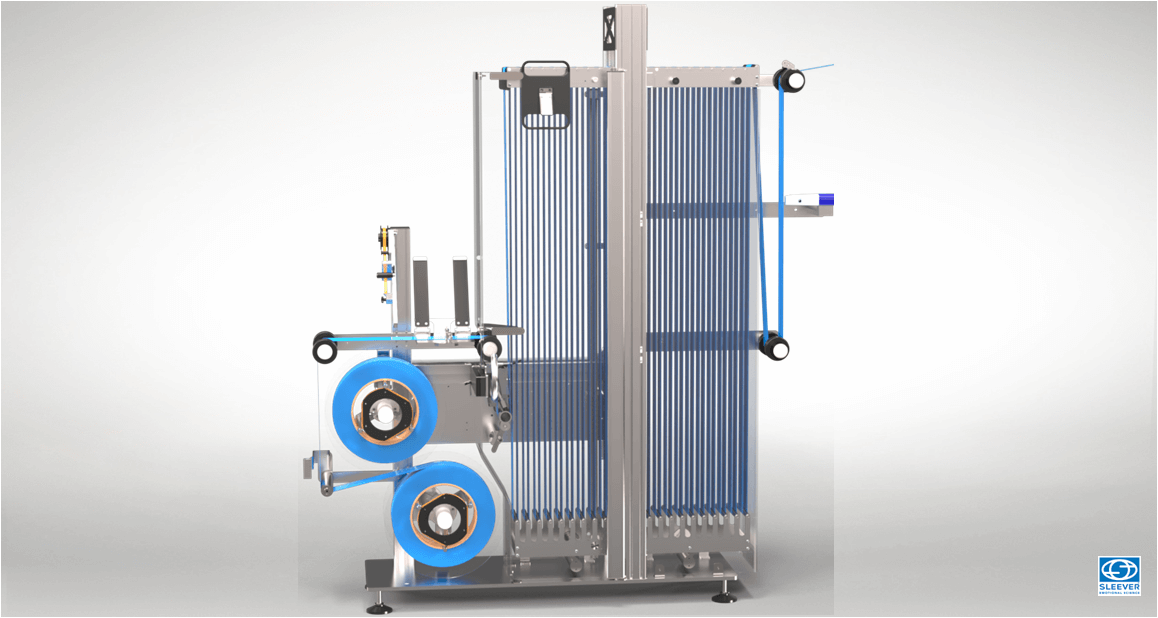

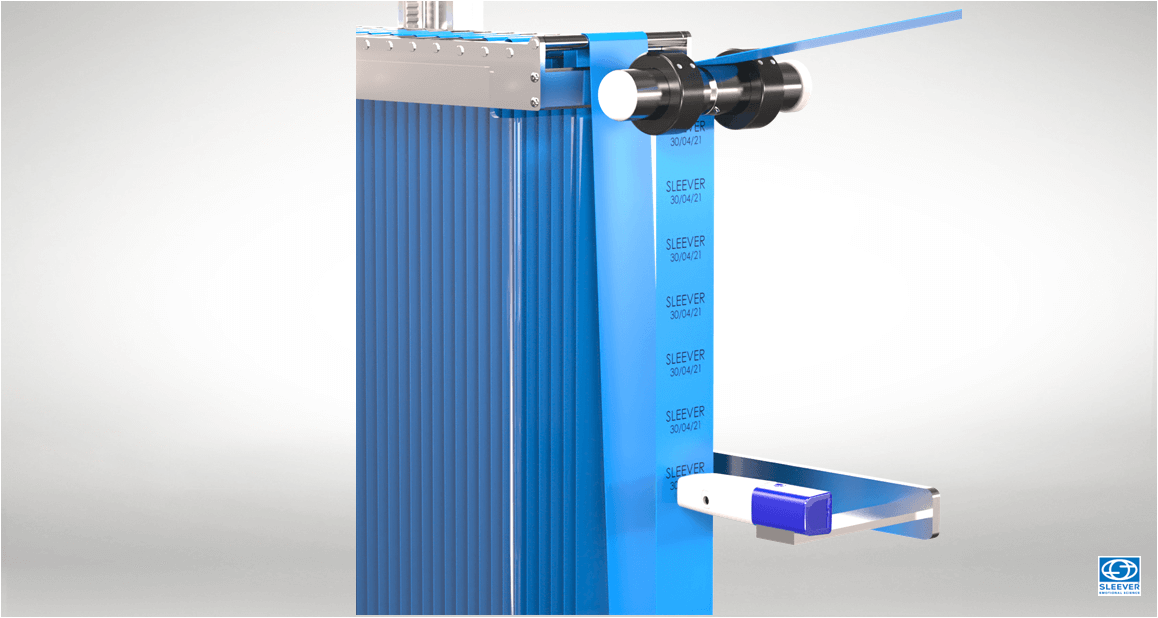

A large capacity sleeve unwind unit for controlled reel changes

The large-capacity sleeve unwind unit, combined with a double reel holder, which can be rotated in relation to the machine axis, is fully enclosed, easy to access and has a large capacity. It offers the operator sufficient autonomy and comfort of use to work at high speed.

Options

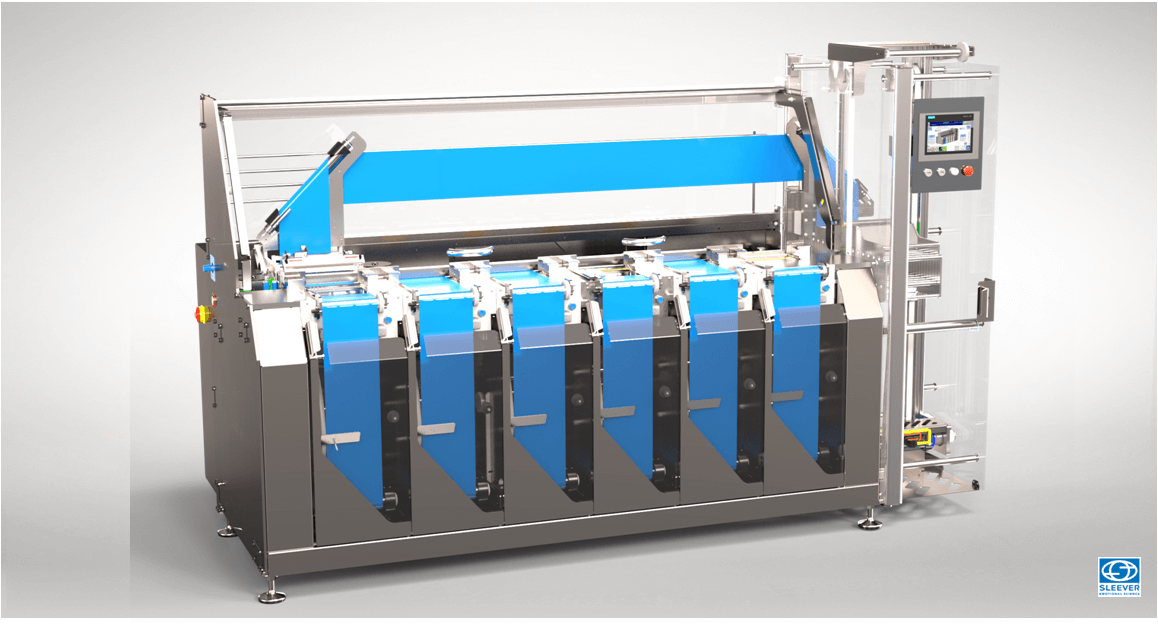

Operator comfort remains the priority for high-speed lines

This machine comes with a multi-reel system and an integrated automatic splicing function. This guarantees "zero machine downtime". It is specially designed for operators who run a line and allows them to increase their autonomy and productivity gains.

When traceability and unit marking are required in the dairy markets

The marking unit is positioned in the large capacity sleeve unwind module for quick and easy access. It allows for various types of marking or coding to meet the needs for traceability and serialization: printing of use-by date, barcode, batch number, and various information concerning the product. Several printing technologies are available: inkjet, laser... and can be adapted to the line speeds of fresh products markets.

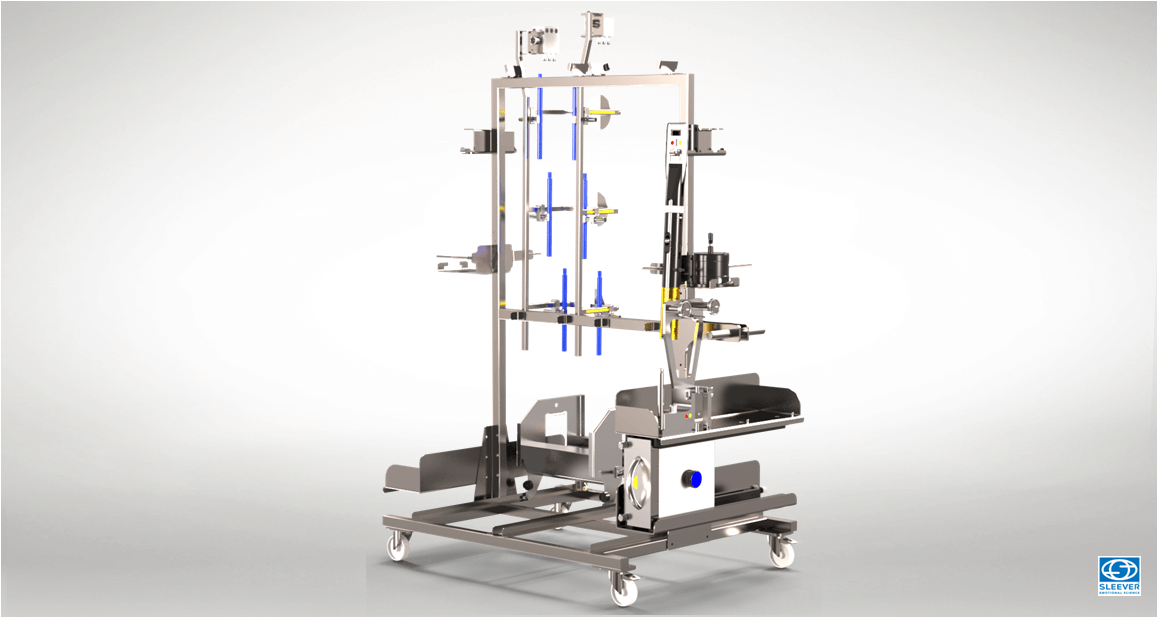

Reduce your format changeover times with the tool trolley

An ergonomic mobile tool trolley, which is light to move, ready for operators, specially designed to store tools and keep them available next to the machine to reduce downtime during format changes. The tools are protected when not in use and when being moved.

Specifications

Machine

| Conveyor height | 980 +/- 50 mm |

| Speed | 400 bpm |

| Cutting diameter | 100 mm |

| Steam consumption | 70 to 300 Kg/h |

| Steam pressure | 6 - 8 bars |

| Electrical consumption | 12 kWH |

| Machine length | 6400 mm |

Packaging

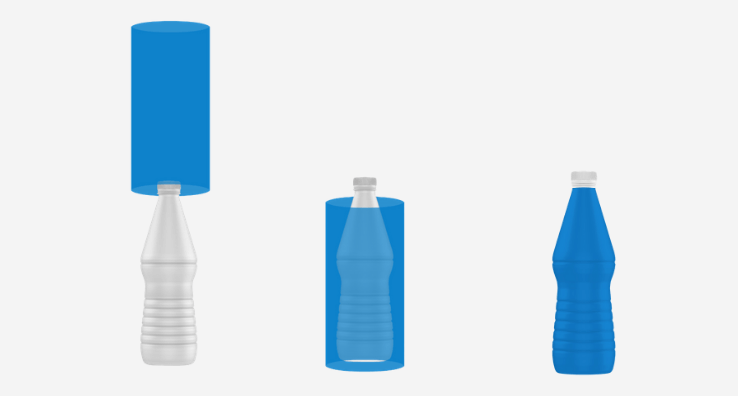

| Materials | PET, HDPE |

| Shapes | Cylindrical, square, oval, complex shapes... |

| Sizes | From 100 ml to 2L |

| Products diameter | From 35 to 80 mm |

| Products height | From 90 to 300 mm |

Sleeves

| fonctionnalité | Habillage intégral |

| Type of films | PET, RPET,... |

| Films thickness | From 40 to 50 microns |