A sustainable label for your PET Packaging recyclability

Our sustainable label solution is specially designed to support and reinforce the eco-design and sustainability of your PET packaging recyclability by allowing its closed-loop bottle-to-bottle recycling.

Leading brands and major actors are already committed in the ecological transition to reach their brands’ sustainability targets without compromising on their image, their DNA, and their products sensory identity.

Nowadays, combining premium image with sustainability products and packaging recyclability is very much a reality.

A sustainable label to strenghten the PET recyclability chain

A Full body and sustainable shrink-sleeve label: The LDPET®

The recyclability and sustainability of a packaging will directly depend on its "associated packaging elements" (caps, labels, container...), which must be separable or compatible with the recycling process.

Our LDPET® (Low Density PET) sustainable label sleeving solution offers the integral full body decoration benefits, in terms of premium decoration and maximized communication surface, for any packaging shape, even the most complex ones.

Compatible with the major steps of the closed-loop clear PET recycling process, it enables PET packaging recyclability by integrating them in the circular economy, allowing the generation and creation of new r-PET packagings.

A multi-awarded and recognized sustainable shrink-sleeve label

Our sustainable shrink-sleeve label, the LDPET®, is approved and recognized by APR (Association of Plastic Recyclers), the major recyclers’ Association in the USA.

Furthermore, and in accordance with the EBBP’s (European PET Bottle Platform) Packaging design and Conception guidelines, this eco-friendly shrink-sleeve label is in compliance with the worldwide PET recyclability practices, to guarantee the closed-loop bottle-to-bottle recycling of PET containers.

The prizes awarded from the professional labels’ experts, (like the AWA Environmental Contribution award), or the equipment and packaging world, are a great recognition that rewards our constant investment in R&D to develop new innovative and sustainable labelling solutions.

Major players in particularly demanding markets such as mineral water have already chosen our LDPET® shrink-sleeve label to accelerate their ecological transition and improve the recyclability of their PET packaging.

Steam or hot air technology: LDPET® promotes the recyclability of PET packaging for all markets

In order to offer all markets a complete decoration solution for PET packaging, ensuring their recyclability in a closed loop, the LDPET product range continues to be developed: LDPET Steam or LDPET Dry-Shrink, brands will find an adapted answer for their recyclable PET packaging.

After the successful launch of LDPET® Steam, for the beverage and cleaning products markets, this product is now available in infrared/hot air technology, for the solid food and cosmetics markets.

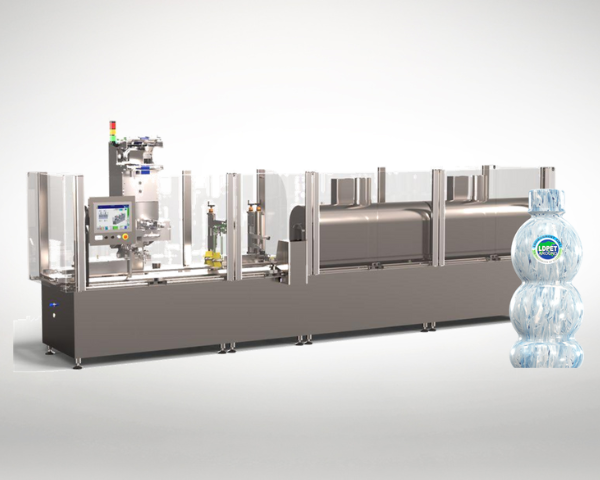

A shrink-sleeve machine offer to apply our sustainable label

To implement our LDPET® sustainable label solution on your products, we offer a vast and appropriate range of equipment designed to fit in with this low density film’s characteristics such as adapting the steam shrinking technology for the soft drinks, home and personal care products, and adapting an infra-red/ hot air shrinking technology for the food and cosmetic products.

Those flexible and modular Machines adjust to your packaging specifications, to accompany you on your ecological transition by integrating your products in a circular economy flow.

All of them are equipped with energy consumption optimization systems.

The testimony of a major player in the mineral water market

The ecological transition is at the heart of Nestlé Waters' strategy: the group has set ambitious energy consumption reduction targets for its Italian facility San Pellegrino, where Levissima mineral waters are filled.

The recent choice of the Combisteam LDPET specialty equipment has enabled the company to meet this challenge and to reach 2 major objectives of its specifications

- Significantly reduce energy consumption

- Benefit from a great flexibility in the use of sleeves, the implementation of different formats of PET bottles, and the integration of modules to improve the efficiency of the filling line.

Discover the complete testimony in video.

A SUSTAINABLE LABEL FOR THE RECYCLABILITY OF PET

Click on the packaging to discover our offer