Accelerate your ecological transition by integrating your PET packaging into the circular economy

- Your packaging decorated with an integral shrink-sleeve label can enter the PET recycling stream

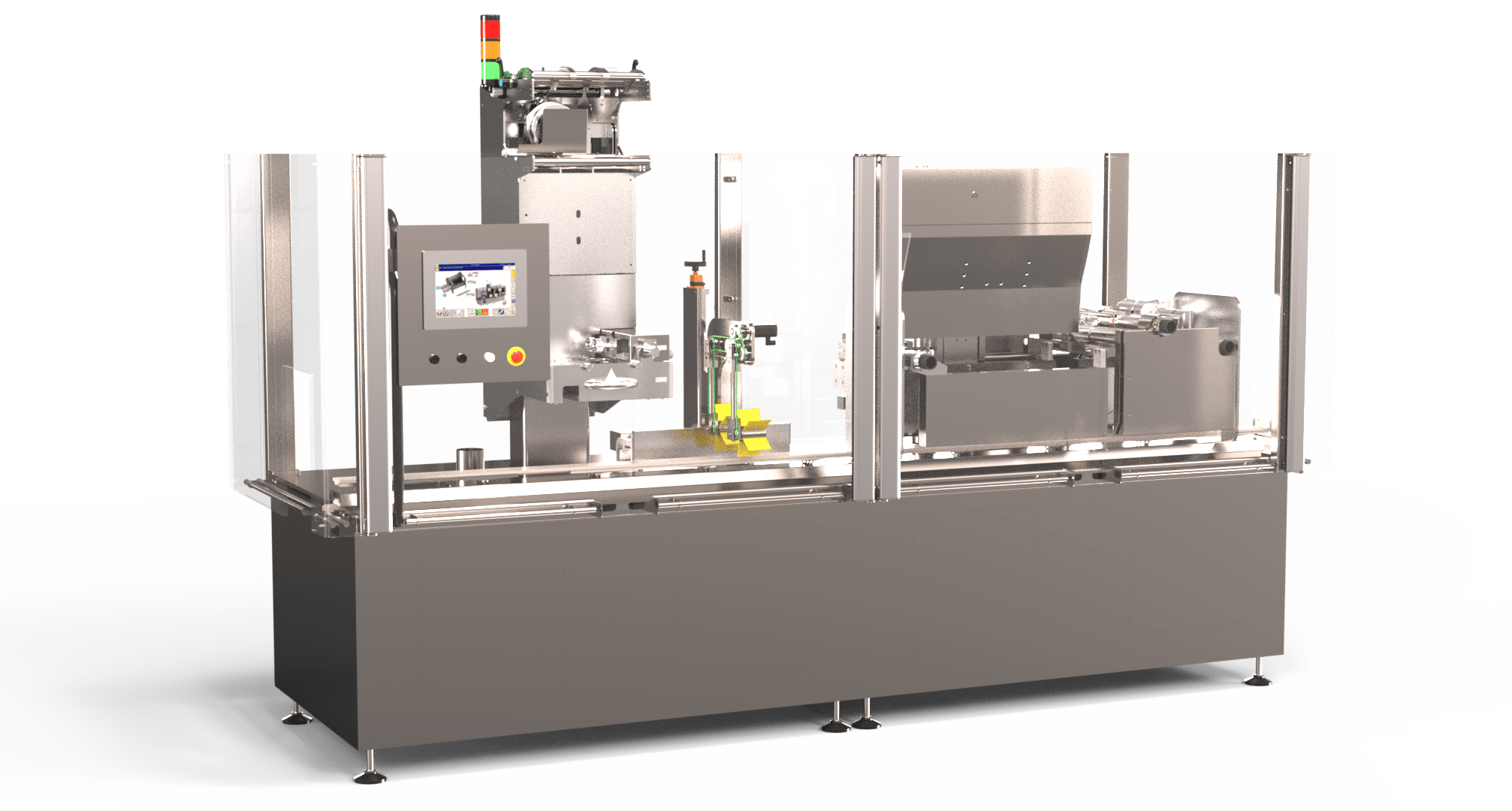

- A modular machine designed for high production rates

- An ergonomically designed shrink-sleeve unwind unit for the operator's autonomy and comfort

- Optimized energy consumption for carbon neutrality

Features

An innovative technology for the recyclability of your PET packaging

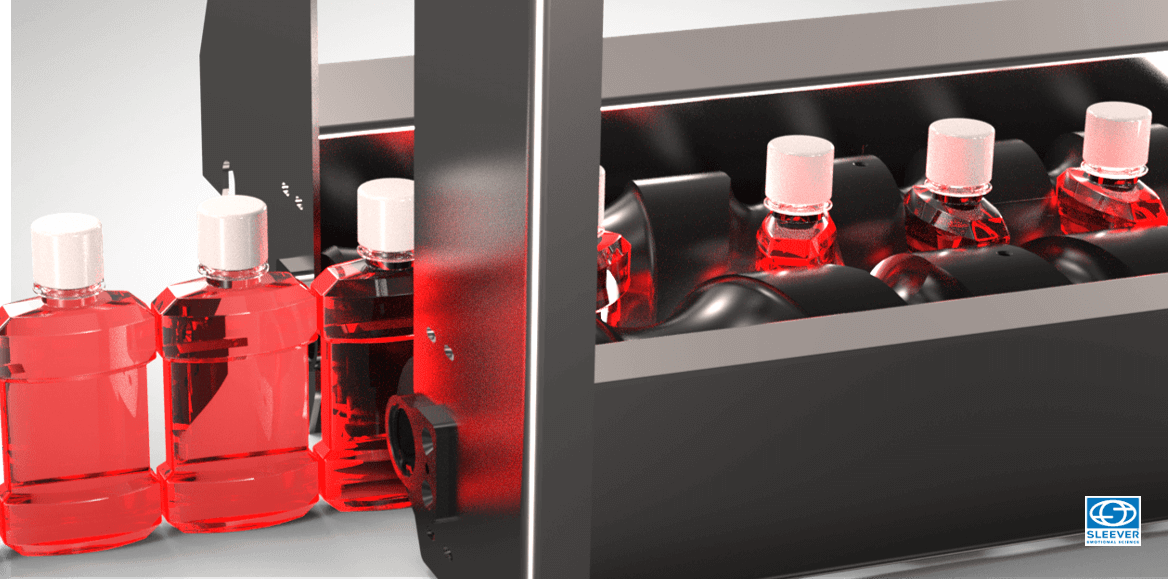

A machine designed to decorate all PET application for moisture and water sensitive product: confectionery, healthcare, food supplements, vitamins and cosmetics. Designed for sizes, from 100gr to 2kg,and for classic and sophisticated shapes. This machine allows the use of LDPET® product, a shrink-sleeve compatible with the closed-loop PET recycling process (bottle -to-bottle).

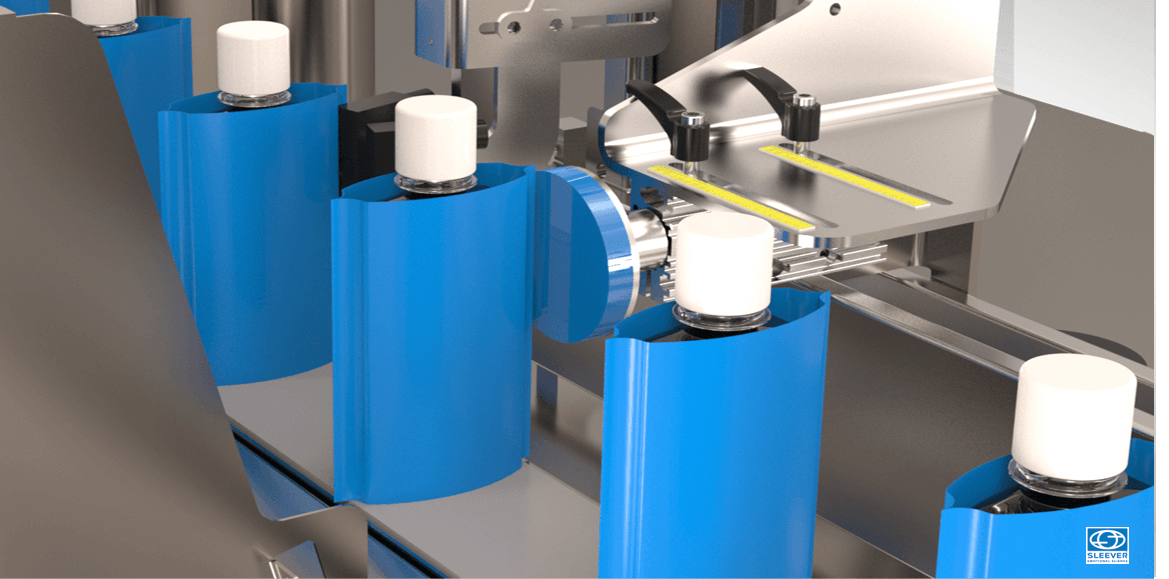

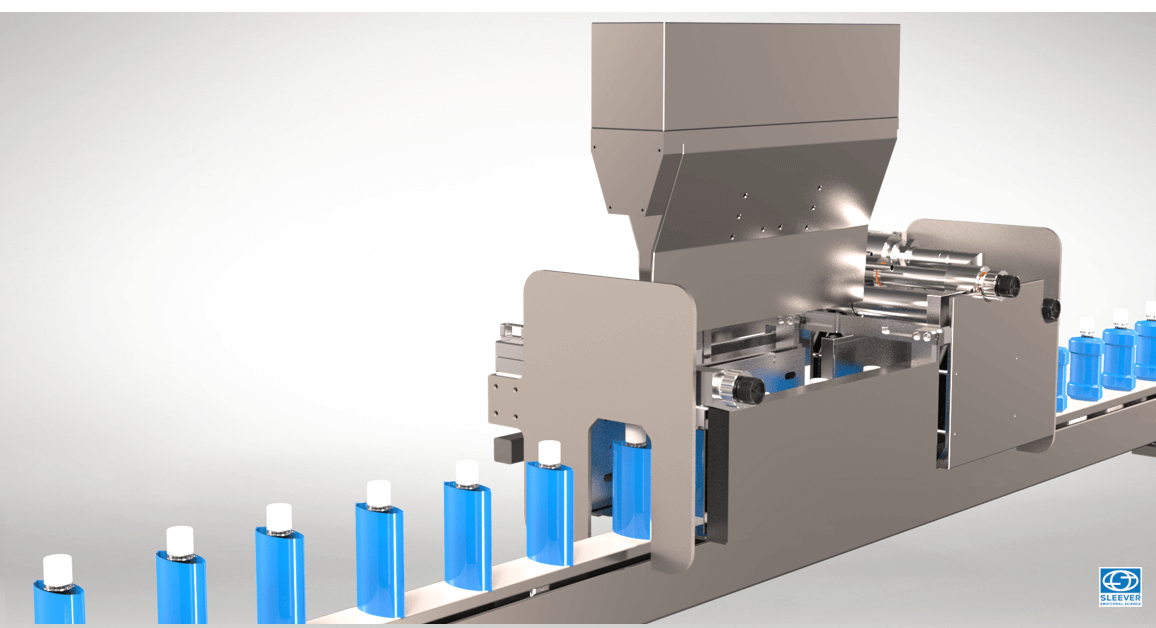

Modules designed for the speeds of markets food, healthcare, and cosmetics

To work at high speed, this machine is equipped with modules to guarantee the performance and quality of your products: an orientation system for complex shapes, and a control and ejection system.

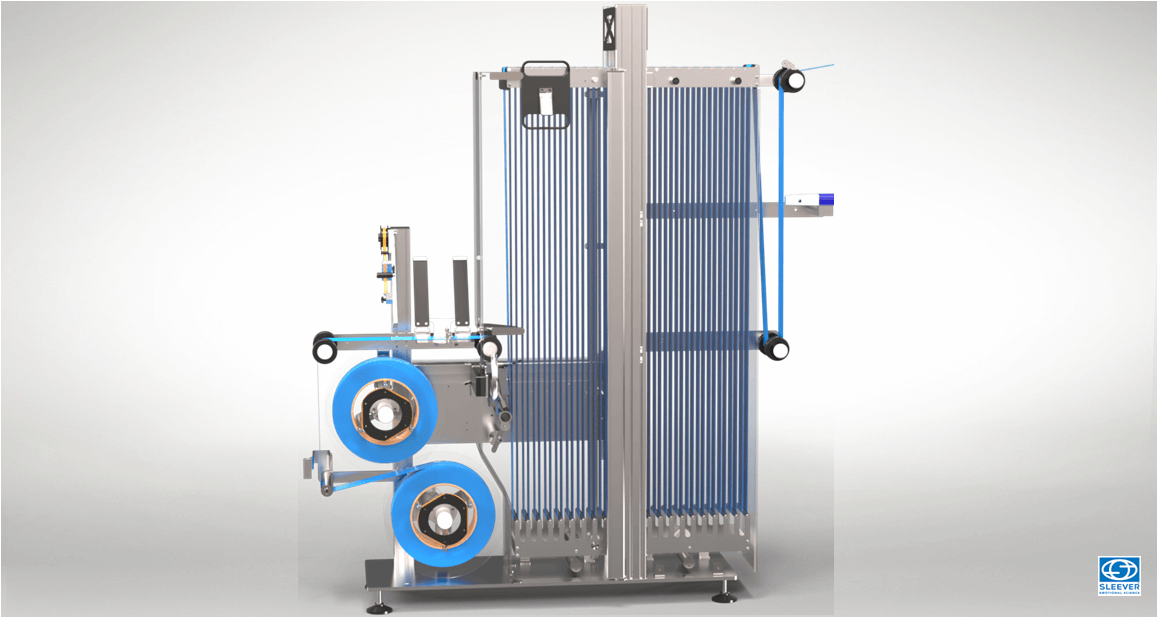

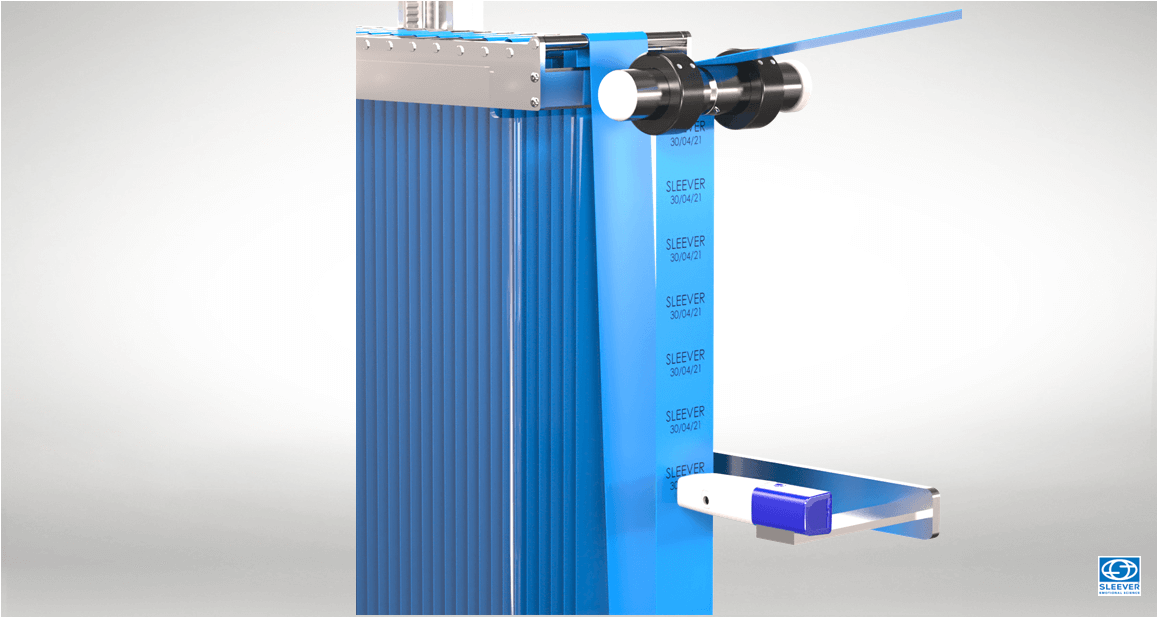

An ergonomic design for quick and easy reel splicing, a large capacity sleeve unwind unit for autonomous use

This high-capacity magazine can handle high sleeving speeds and is designed to accommodate new generation films. Located outside the machine, it offers easy access to the reels, which are positioned at hand level; the splicing table allows for quick and error-free splicing. The overall system provides autonomy and ergonomics, for operator comfort.

Energy management to reduce the carbon footprint of your products

This exclusive shrink technology combines several systems: the infrared technology adjustement, the height-adjustable tunnel and the skinner diffusion system are adjusted to each product to optimize energy consumption.

Options

The assurance of a well-oriented facing

The orientation module in the screw ensure the correct positioning of the PET packaging before the shrink-sleeve application station. We take into account the specificities of your packaging (management of your shapes).

We have made modularity the secret of your performance

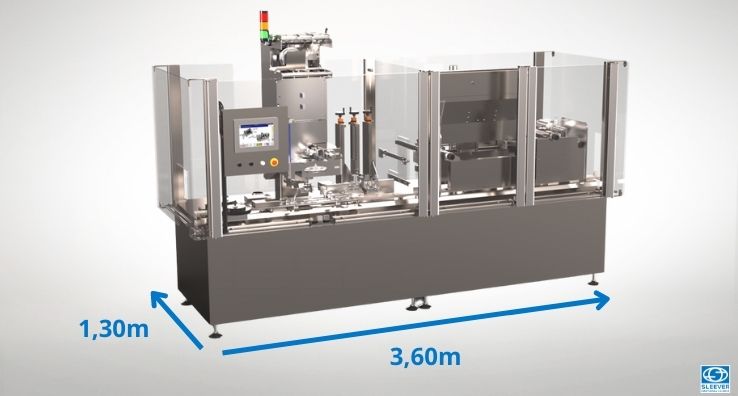

This compact, all stainless steel monobloc machine can be enhanced with different modules to meet your productivity needs, from 21000 to 36,000 container /hour.

When traceability and unit marking are required in the markets

The marking unit is positioned in the large capacity shrink-sleeve unwind module for quick and easy access. It allows for various types of marking or coding to meet the needs for traceability and serialization: printing of use-by date, barcode, batch number, and various information concerning the product. Several printing technologies are available: inkjet, laser... and can be adapted to the line speeds of your products markets.

For multiple communication uses

This module allows for communication with upstream and downstream machines to regulate the line and improve efficiency. Being connected allows you to open up to the outside world and allows for remote assistance, which can be used for diagnosis and remote intervention if necessary. A solution that optimizes travel costs for certain interventions and saves time.

Specifications

Machines

| Conveyor height | 980 +/- 50 mm |

| Speed | 300 bpm |

| Cutting diameter | 100 - 130 mm |

| electrical consumption | 80 KW/h |

| Machine length | 3600 mm |

Packaging

| Material | PET |

| Shapes | Cylindriqcal, complex shapes... |

| Product diameter | 45mm - 125 mm |

| Product height | 100 - 200 mm |

| Sizes | 50 gr -1 kg |

Sleeves

| Applications | Full body |

| Films | TPEG, PET |

| Film thickness | 55 microns |