Transparent glass bottles and vials: the security solution

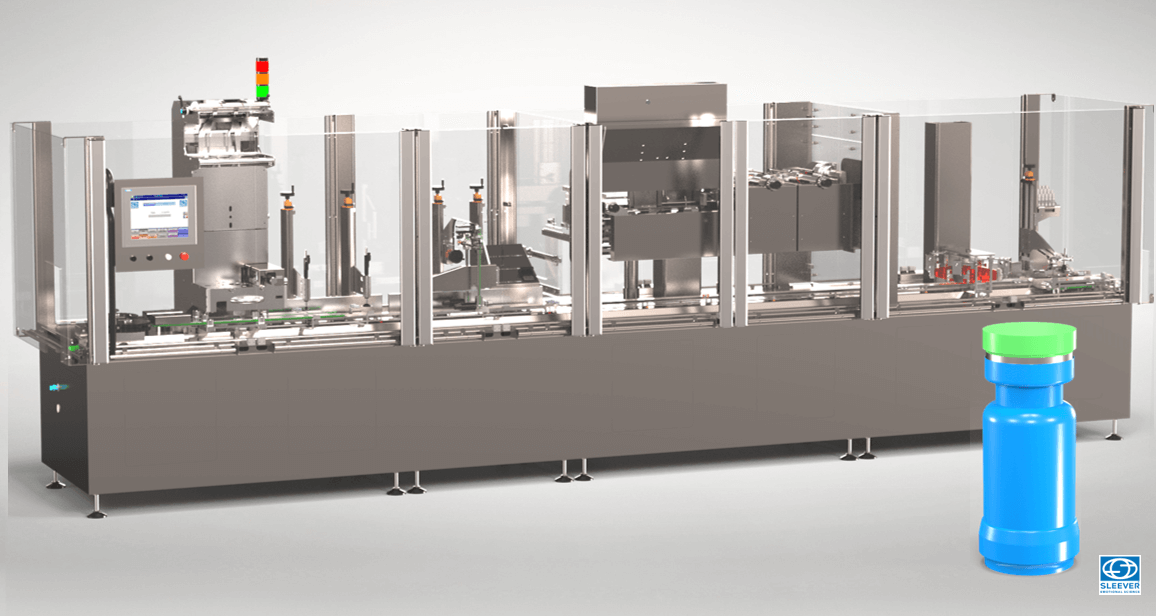

- A unique protection and security system for glass bottles and vials containing delicate cyto-toxic products

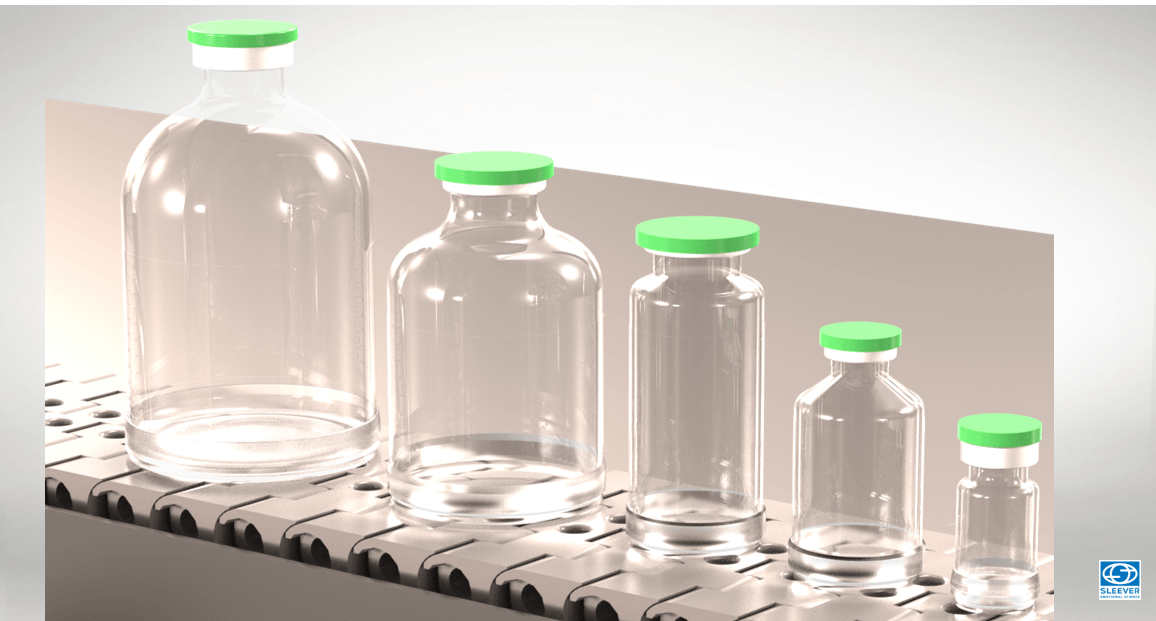

- Handle multiformats with a range of glass vials from 2 ml to 100 ml

- Reliability of the process at high speeds, even for the lightest products whose weight can be lower than 10 gr

- Monitoring and control of product temperatures

- Hot air shrink technology adapted to your product specifications

Features

Technology dedicated to the protection and security of cytotoxic products

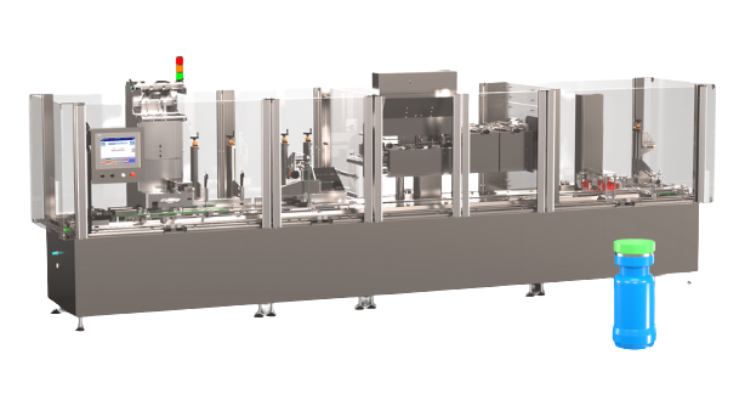

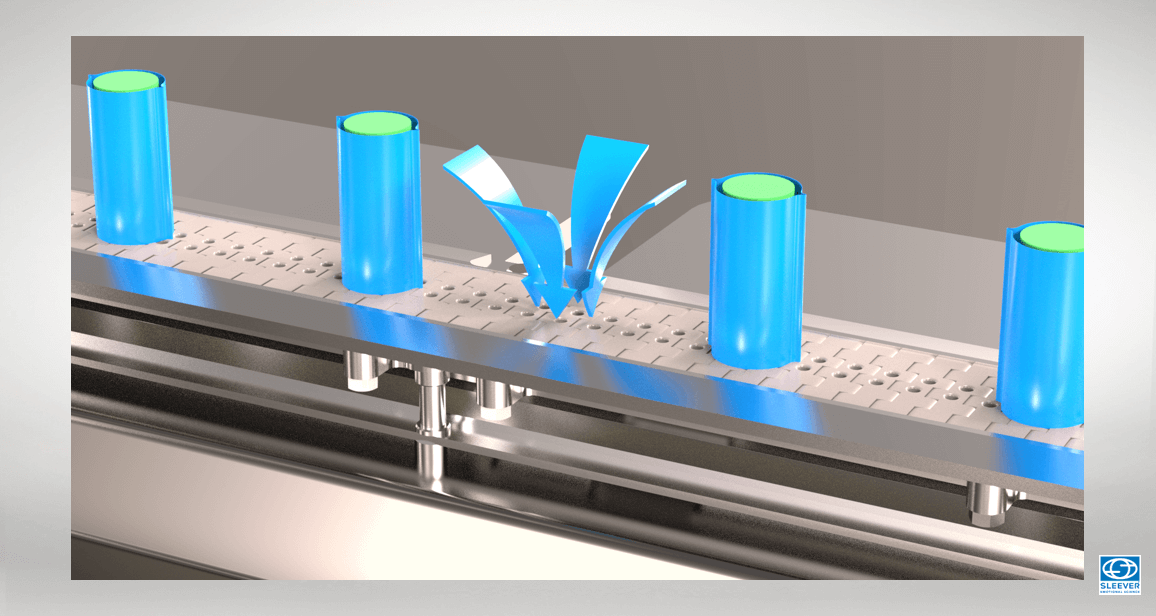

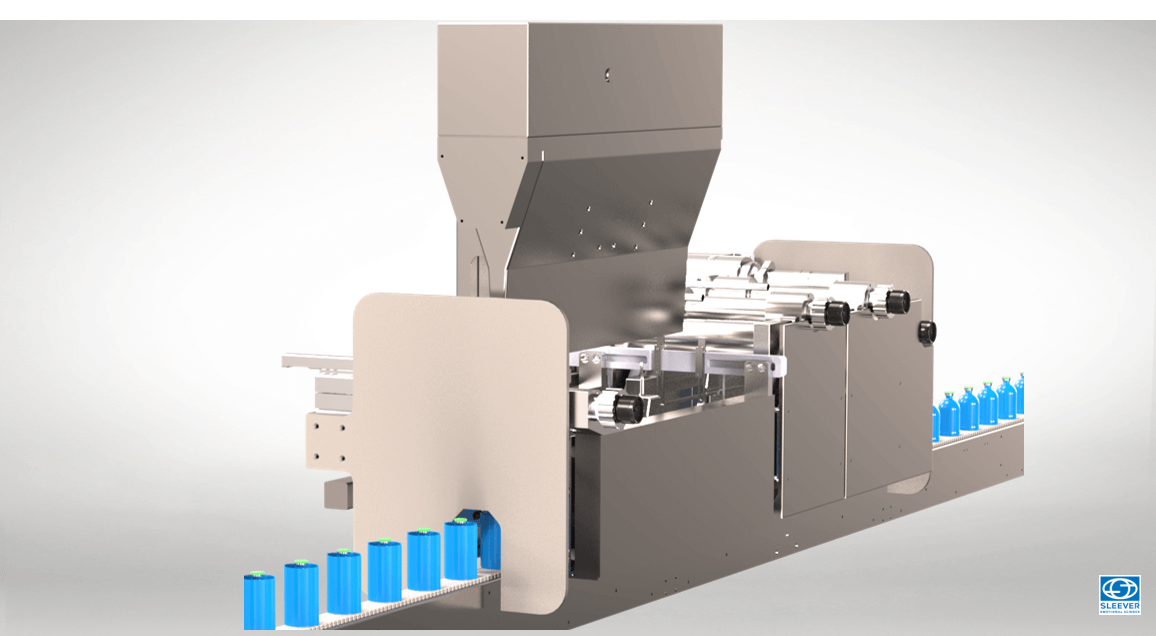

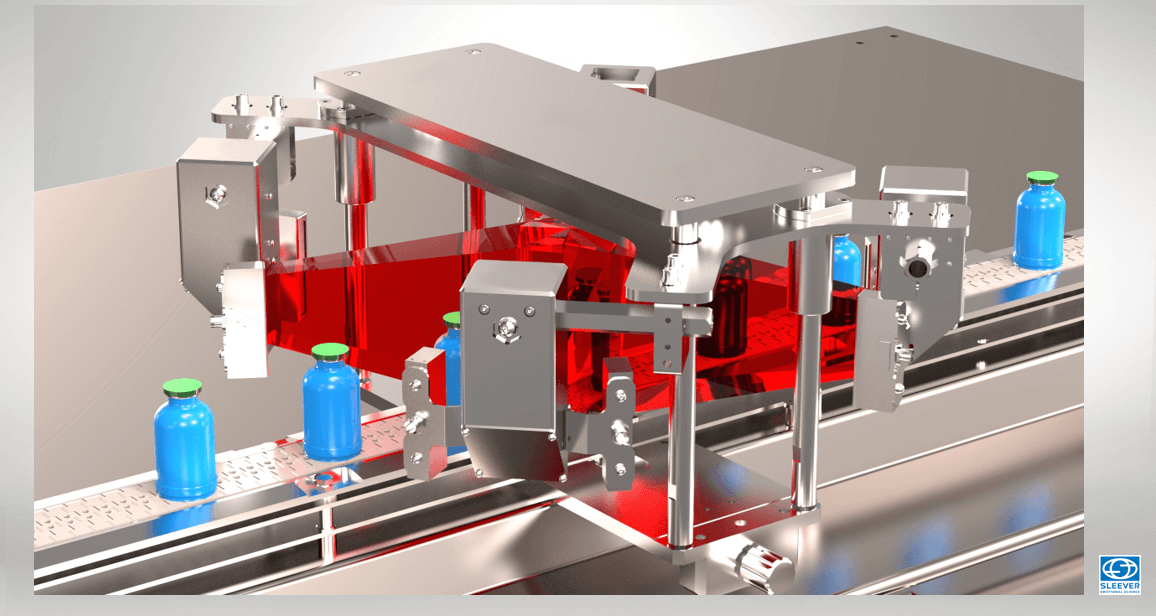

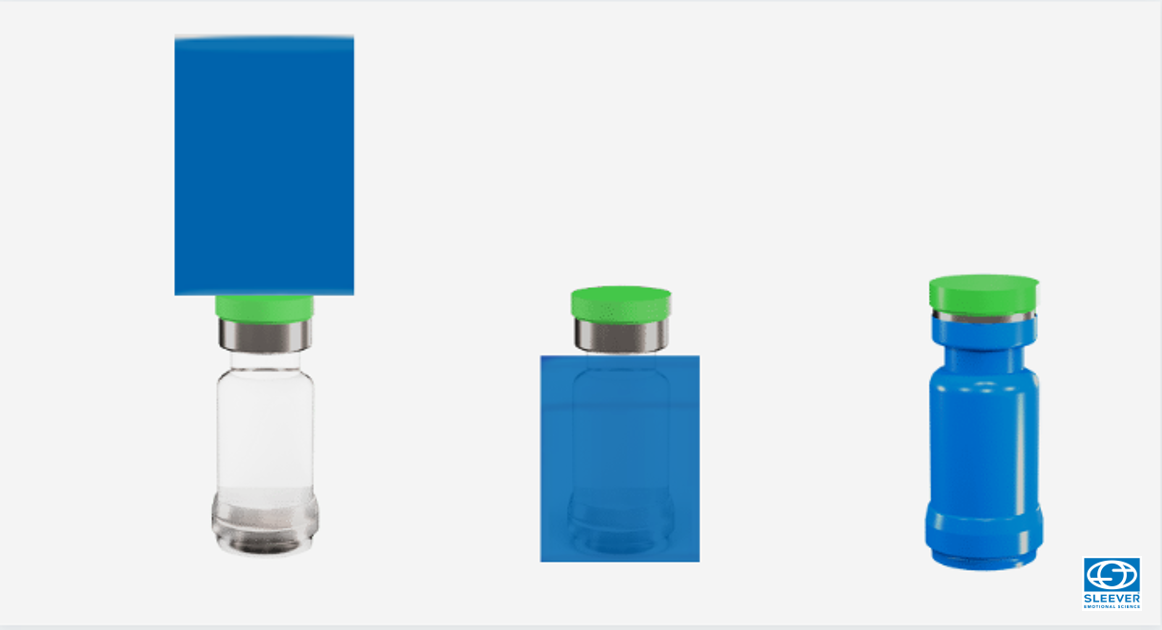

Cytobloc® is a unique solution for protecting and securing transparent glass vials to protect personnel from contamination during handling. Composed of a cup and an anti-breakage shrink-sleeve, its implementation involves a lateral, upper and lower guidance system throughout the process.

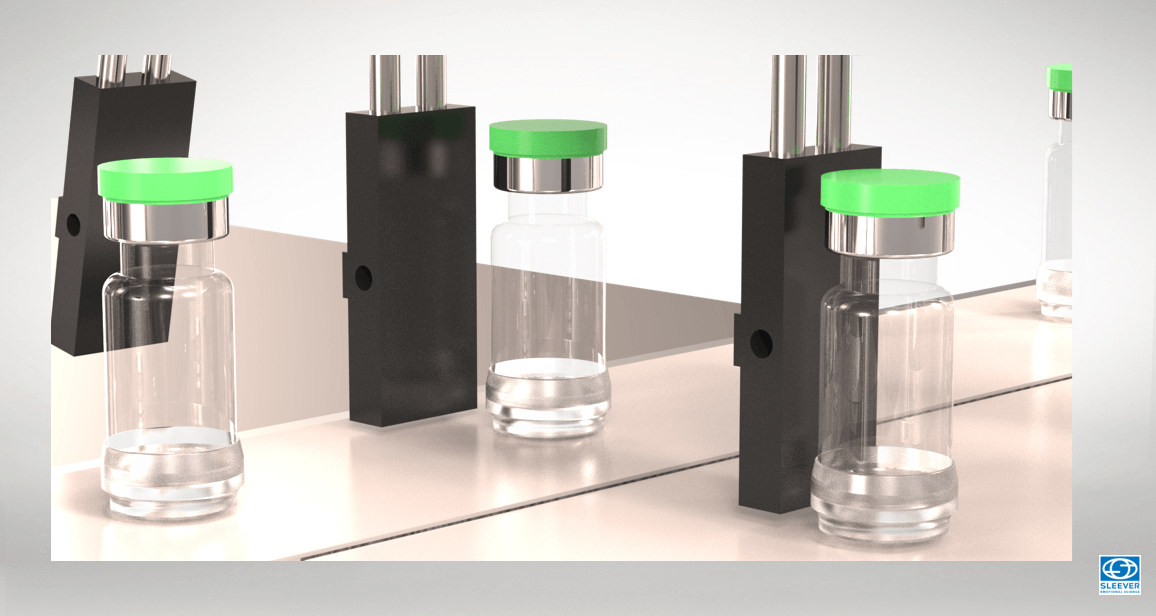

Mastery of multi-format management of extremes

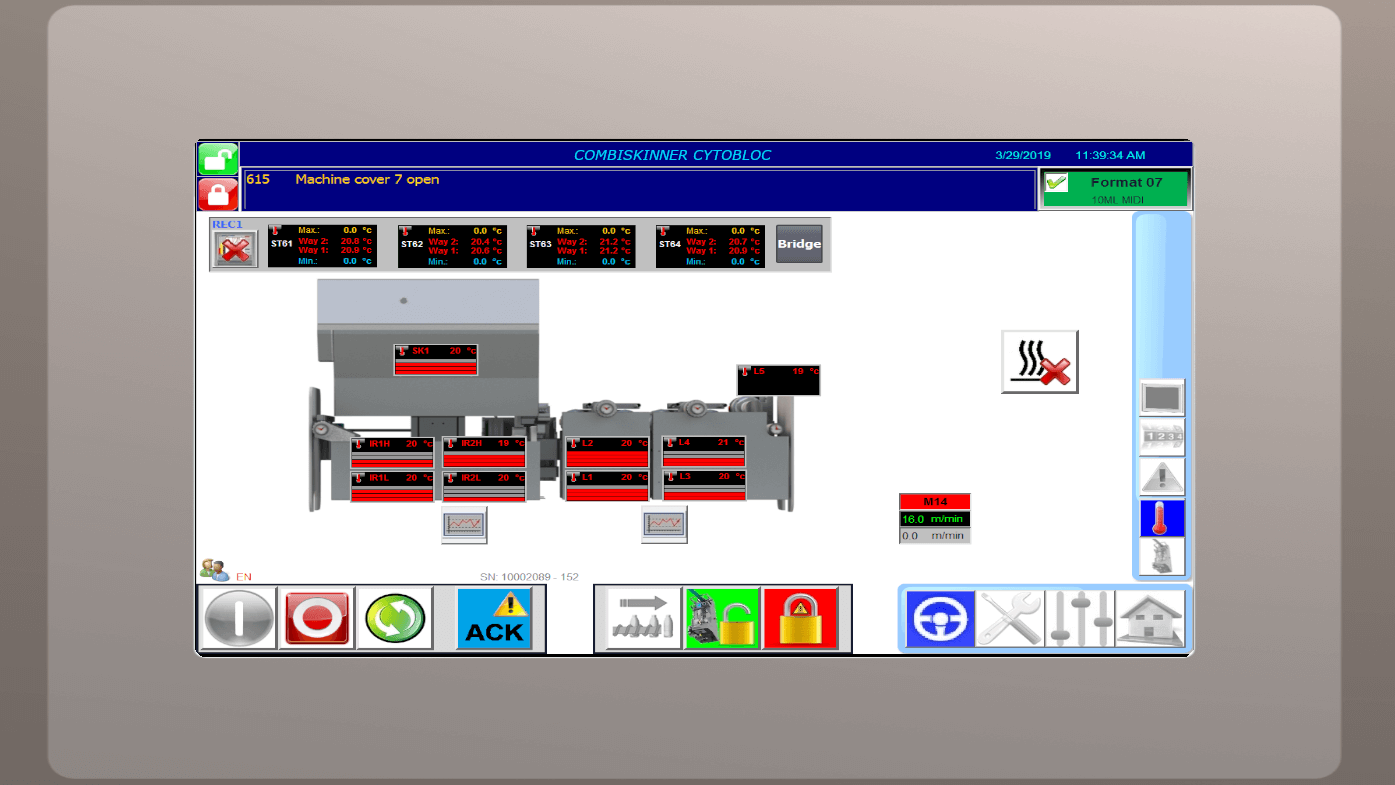

This equipment is specifically designed to handle the particularly wide range of cytotoxic product containers, from 2 to 100ml, on more than 10 different formats. The tooling includes common elements and elements specific to each format. Format changes can be made without tools, and settings are pre-saved in the interface and automatically synchronized, for quick and easy operations.

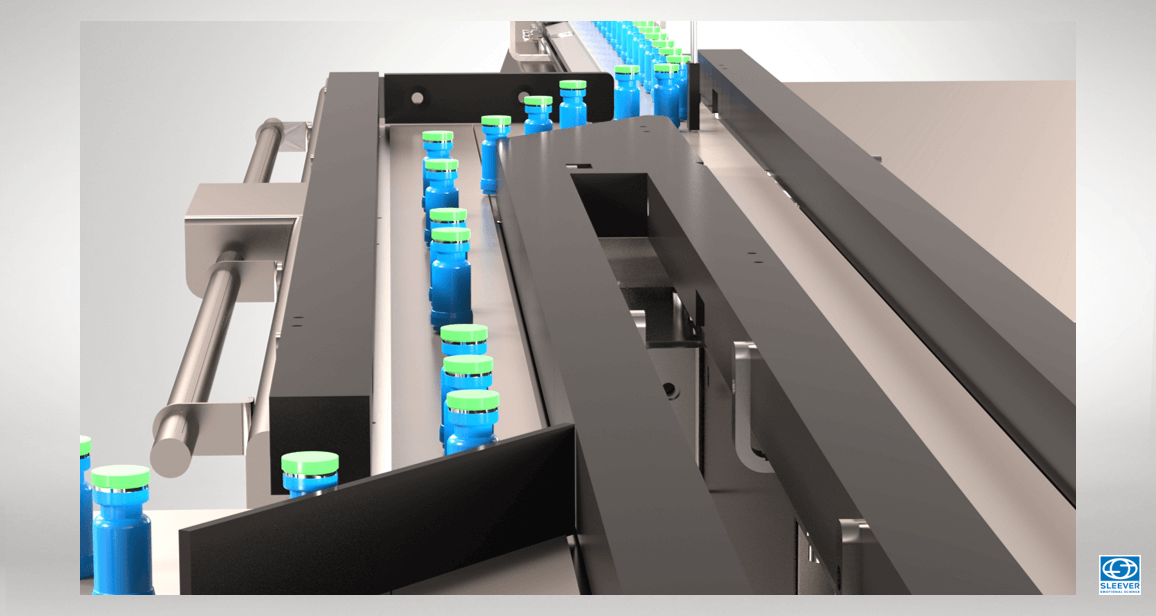

A technology adapted to the high speed of feather weights' products

An adapted technology that allows products weighing less than 10 grams to be held upright at 300 products per minute, from the machine entrance to the shrink-sleeve application, without loss of pitch, and a confirmation system for shrink-sleeve application without loss of pitch until the shrink tunnel entrance.

The guarantee of a product at the right temperature

Different temperature sensors are installed in the shrink tunnel. The first ones are used to ensure the right shrink temperature of the shrink-sleeve and the second ones are used to measure the temperature deviation for the safety of the product. If the temperature increases, the information is transmitted to the operator for corrective action and then recorded for the traceability of the product. Then communicate to a server located outside the machine.

Hot air shrink technology adapted to sensitive products and optimized consumption

The hot air shrink tunnel ensures that sensitive products are not altered during the shrink-sleeve label shrinking phase. Each recipe has its own adjustment and memorized temperature for both the infra-red ramps and the hot air nozzles which ensure the finishing of each product. The settings per recipe allow to control and optimize the energy consumption for each format.

Options

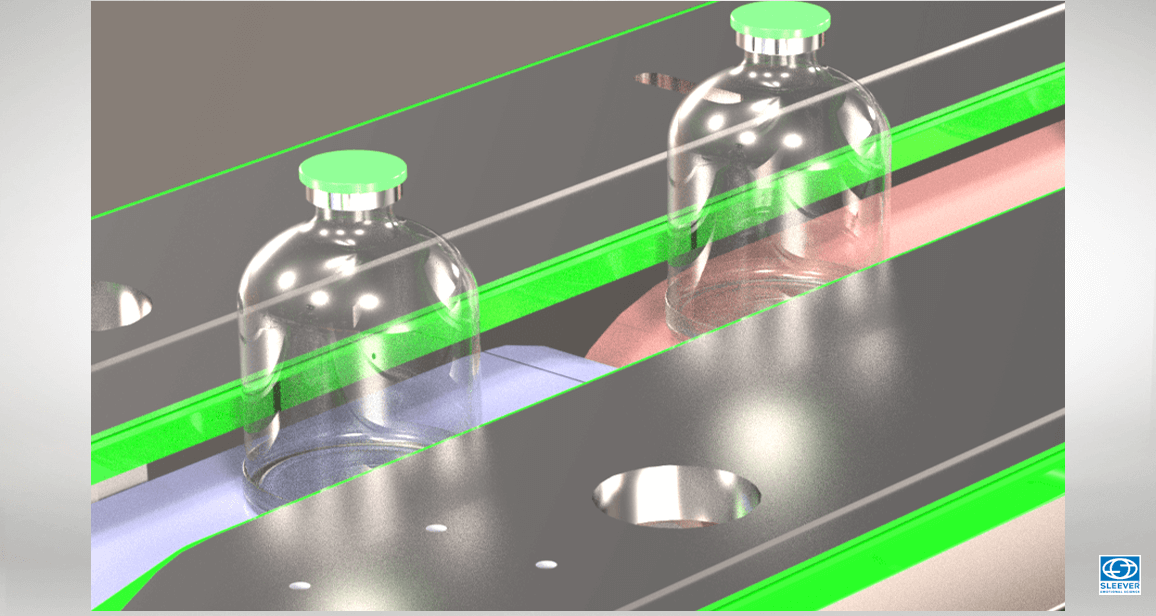

Separate conveyors to break the thermal bridge

The product transfer conveyors are dissociated, thus avoiding the transfer of calories to the products upstream of the machine and avoiding any alteration of the products during the accumulation phases at the machine entrance.

360° product control

A control system with 4 cameras allowing a 360° control around the product twice: after the shrink-sleeve apply and after the shrinking. This system is connected to an ejection system and a line clearance in case of anomaly.

High speed upright product ejection without dropping them

The ejection module has been specially designed to discard light and unstable vials running at high speed, while keeping them in an upright position, so that they are not altered during the operation.

Line clearance in case of machine stop

The line clearance module avoids any alteration of the products in case of machine stop.

This module avoids keeping products in the shrink tunnel during a stop due to a production anomaly.

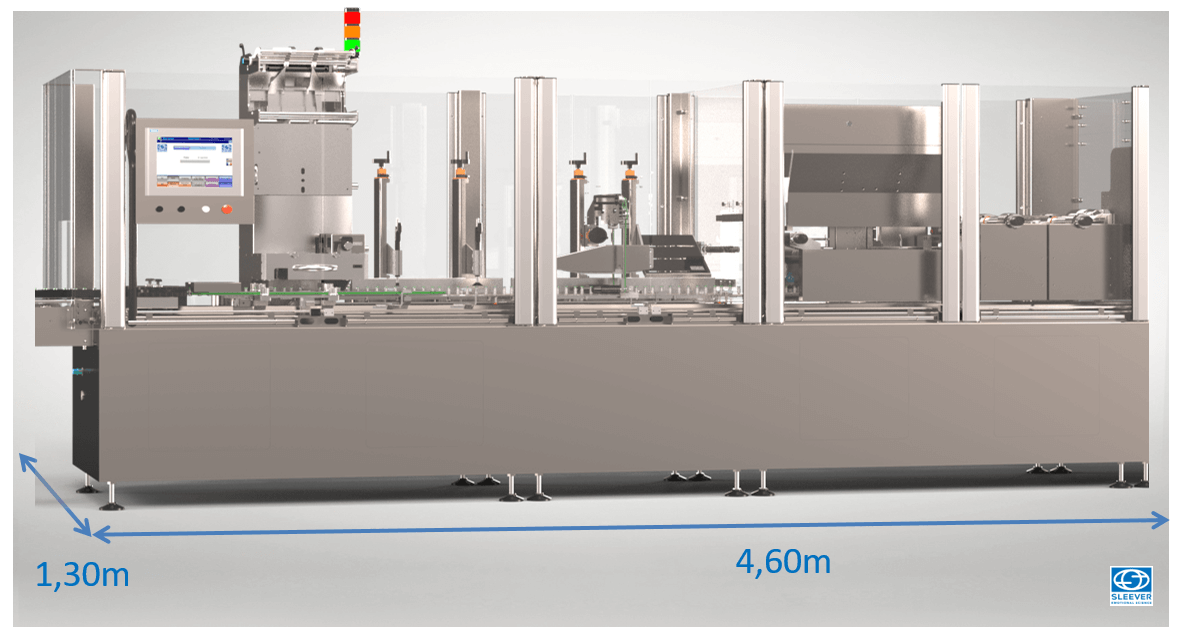

Specifications

Machines

| Conveyor height | 980 +/- 50 mm |

| Speed | 300 cpm |

| Cutting diameter | 100 mm |

| Electrical consumption | 59 KW/h |

| Machine length | 6400 mm |

Packaging

| Materials | Glass |

| Shapes | Cylindrical |

| Product diameter | 15 to 65 mm |

| Product height | 32 to 95 mm |

| Sizes | 2 - 100 ml |

Sleeves

| Applications | Full body with protective cup on its base |

| Films | OPS |

| Film thickness | 95 microns |