For food, home care,personal care and pharmaceutical markets, everything is designed to ensure that tamper evident is visible to the consumer

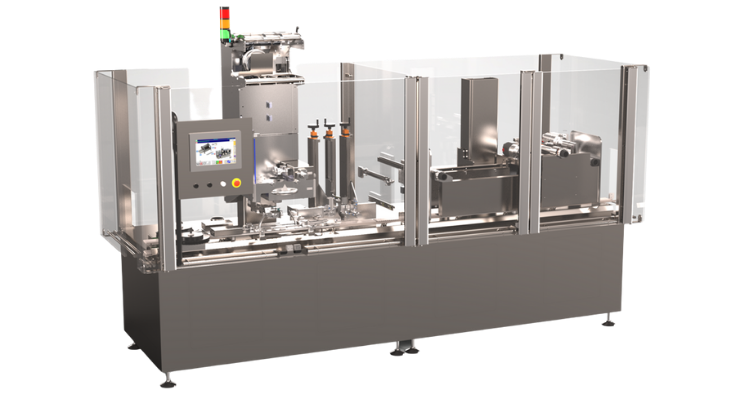

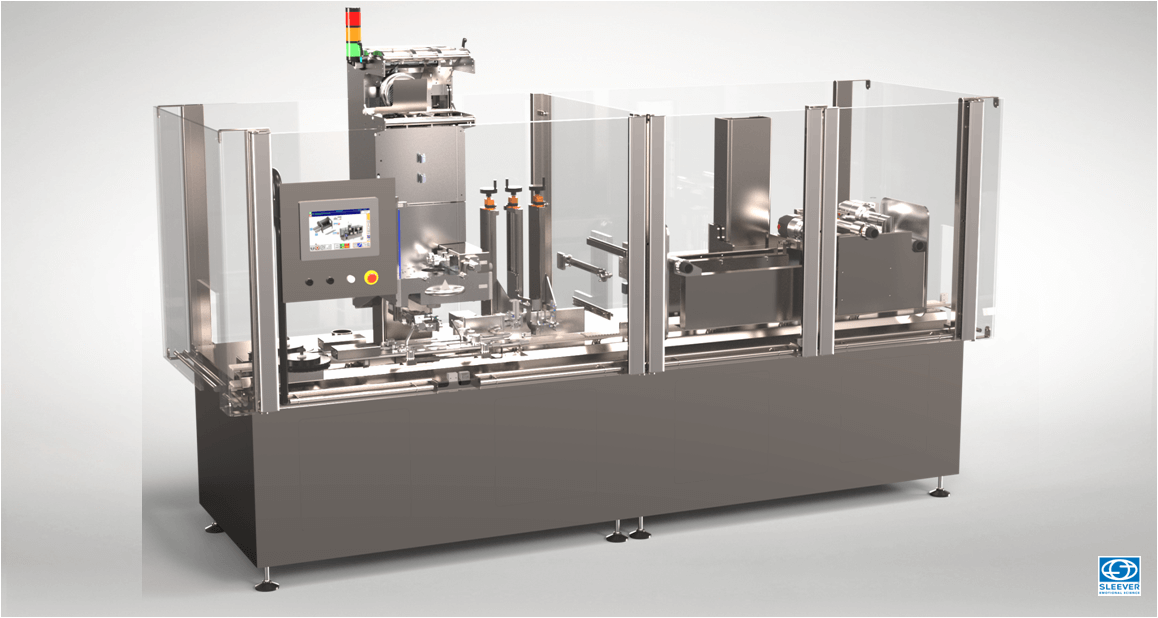

- A tamper evident band applicator machine designed to secure everyday products for the food, hygiene and healthcare markets.

- Intuitive, and Easy to use, this labelling equipment is adapted to all your formats' changes, allowing you to have a great degree of flexibility: multiple materials, shapes and capacities.

- This tamper evident labelling machine can be adapted to host additional modules to ensure the correct positioning of your tamper-proof shrink band.

- Hot air shrinking technology tailored to your product specifications

Features

A tamper evident machine for a protected label and product

An all stainless steel tamper proof shrink banding machine that meets the specifications of the food, hygiene, pharmaceutical and healthcare markets, and of brands and contract packers.

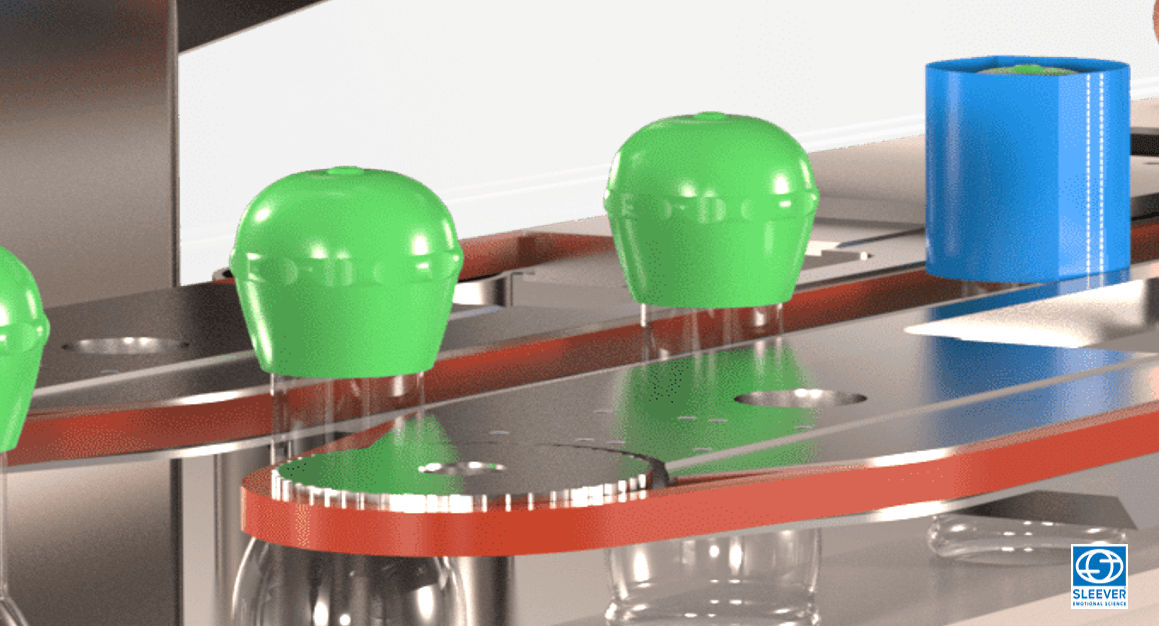

A tamper-proof equipment's design that has been studied to protect the label during every phase: from transfer with specially polished selection screws, to Teflon guides that never cause friction on the label, to the on-the-fly application that guarantees that there is no contact between products.

A tamper evident labelling Machine with an easy format changeover

Flexibility, a necessity to go from a mill to a pepper box, from glass to plastic, from one capacity, one diameter, one shape to another. This tamper proof labeling machine comes with a dedicated set of tools for each format, to provide the required flexibility for on-the-go adjustments.

Their tool-less set-up and easy adjustments allow for quick restarts for frequent format changes in production.

Tamper proof machine with custom Modules to secure your products

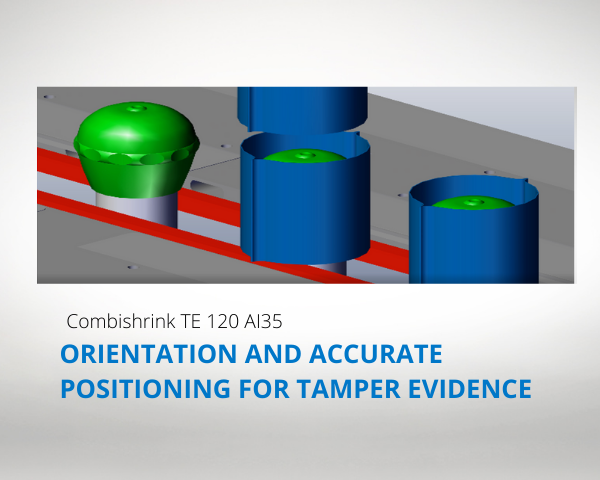

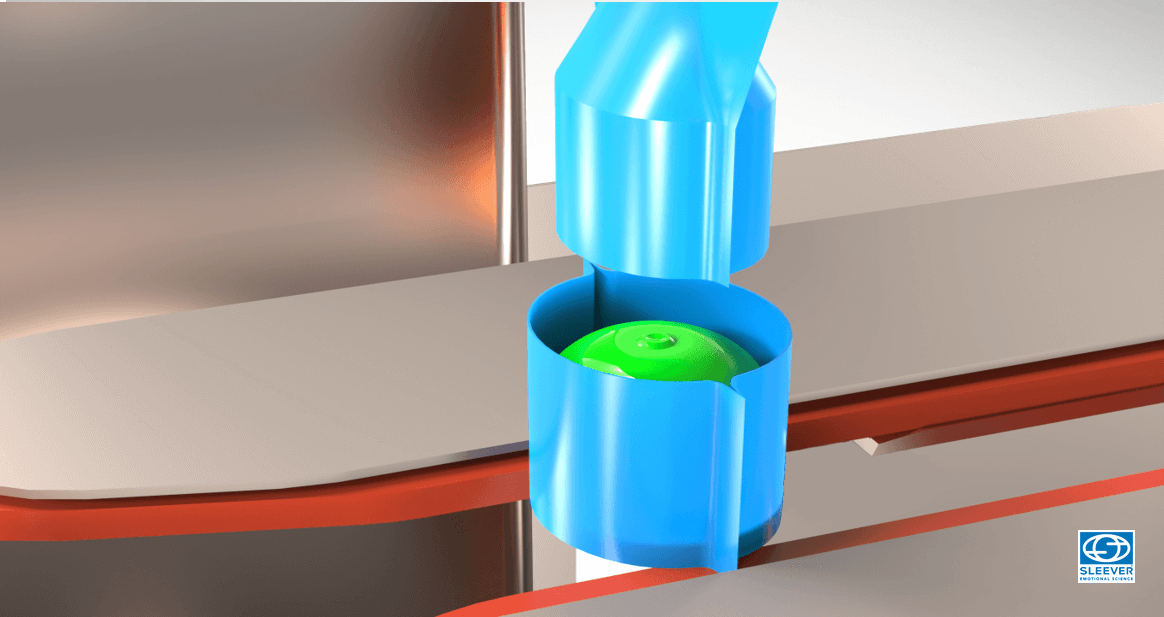

The security function uses different modules depending on the shape and diameter of the products.

A blocking system guarantees the shrink band application at the right height, and a sleeve orientation module allows to avoid sagging and fixing nozzle to ensure the transfer of the label.

These systems ensure the correct positioning of the guarantee of first opening, allowing for an easy identification and visibility by the consumer.

Tamper evident labeling machine for an optimized consumption

This tamper proof labelling machine includes a flexible and versatile hot air shrink tunnel to ensure that sensitive products such as food (boxes of chocolates, sauces), skin care or hygiene creams are not altered during the sleeve shrinking phase.

Each recipe has its own adjusted and memorized temperature for both the infrared ramps and the hot air nozzles that ensure the finishing of each product. The settings for each format allow you to control and optimize the energy consumption for each format.

Options

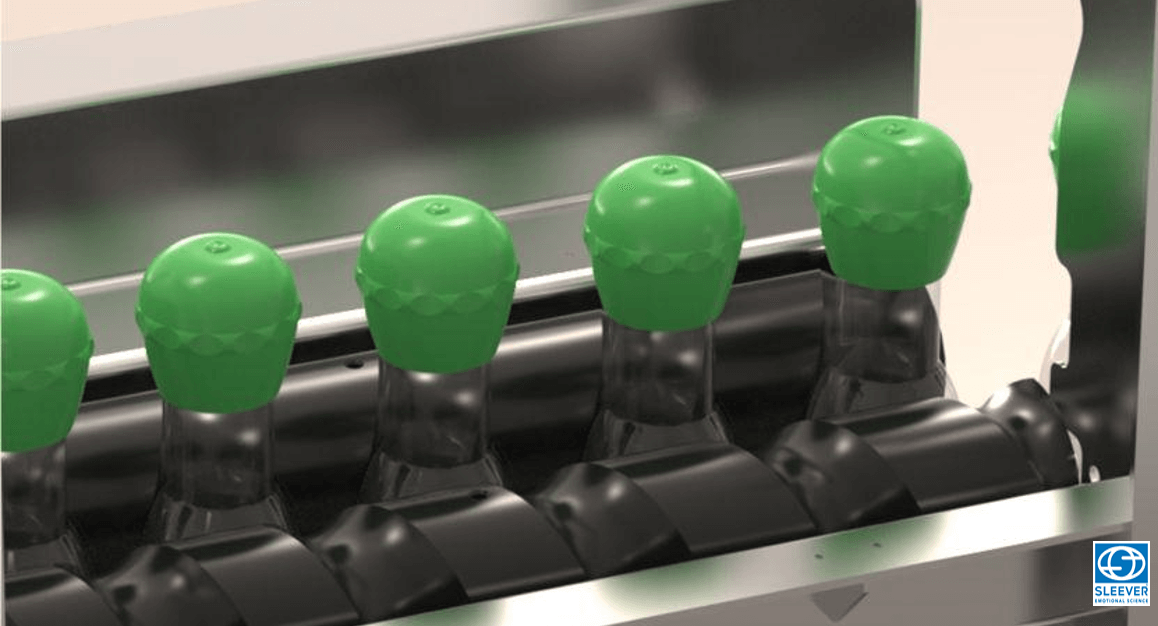

The guarantee of a well-positioned tamper evident shrink band

This module composed of two belts allows you to position the sleeve at the desired height to ensure that the tamper proof shrink band will be positioned at the right height to guarantee the first opening, by securing bottles' caps, lids, mills, liquid soap pumps, pouring spouts...

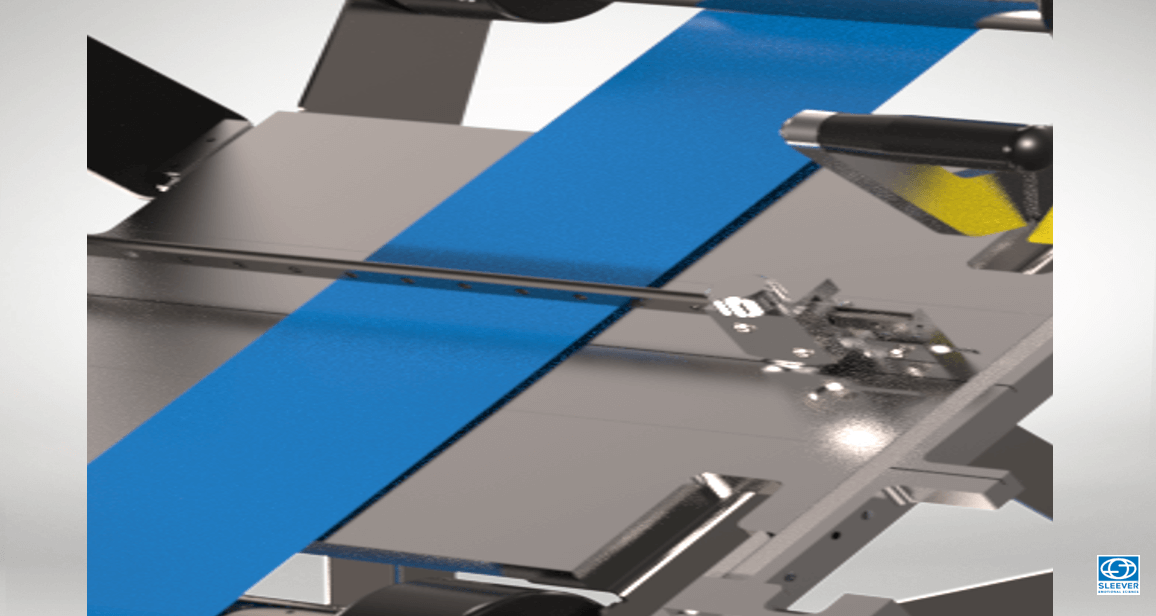

A Marking Module for your tamper evident banding operations

This tamper proof labelling machine module allows to mark the labels to include critical information : guarantee the traceability of the product, its origin, the specification of its use-by date and compliance with constantly changing regulatory specifications. It can be used for coding in logistics and distribution for barcodes or datamatrix. The technology used is set up and adapted according to products' specifications (inkjet, laser ...).

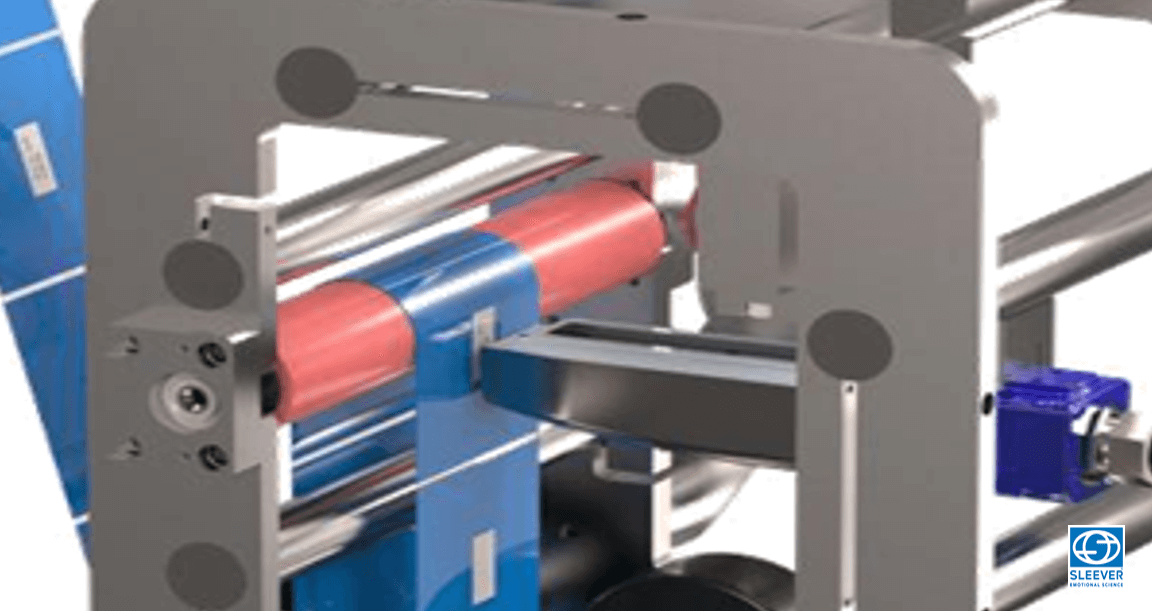

Reel junction Module for Tamper evident labelling machine

When changing reels, the quality of the sleeve splice is a guarantee of productivity. The splicing table is equipped with a double locking system, a secure system, and an adhesive tape dispenser.

This provides comfort and safety for the user while guaranteeing a smooth, intuitive and fast reel change-over.

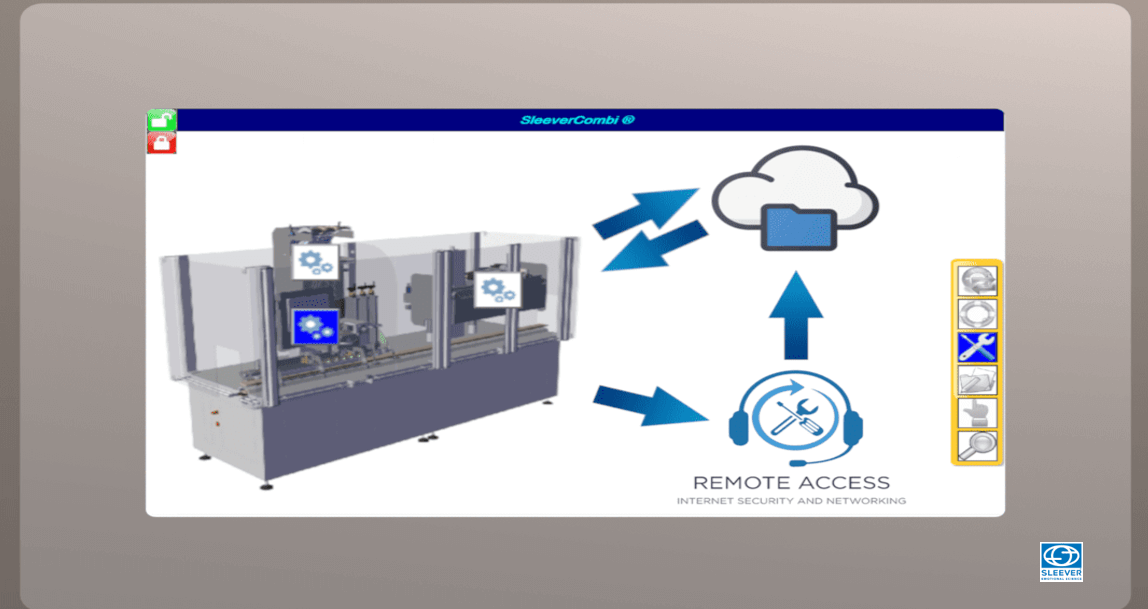

Interactive and interconnected tamper evident labelling machine to secure your products

This Ethernet module allows to communicate with the whole production line, with both the upstream and downstream machines to regulate the line and improve the efficiency of your tamper evident labelling operations. Being connected allows you to open up to the outside world and allows for remote assistance, which can be used for diagnosis and remote intervention if necessary. A solution that optimizes travel costs for certain interventions and saves time.

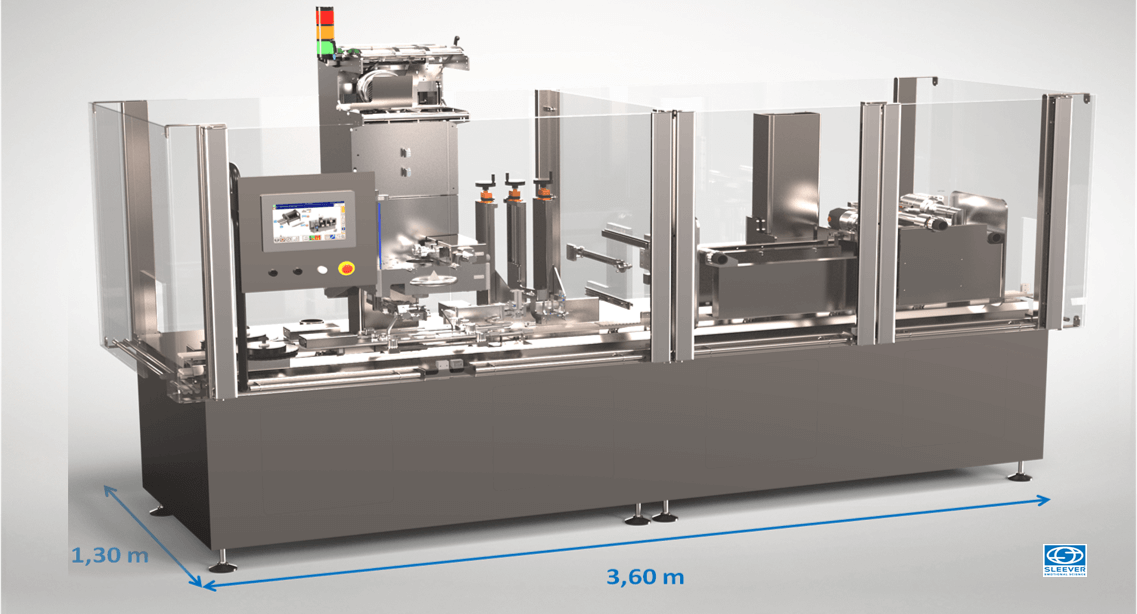

Specifications

Machine

| Conveyor height | 980 +/- 50 mm |

| Speed | from 150 to 200 bpm |

| Cutting diameter | 100 mm |

| Electrical consumption | 25 kW |

| Machine length | 3600 mm |

Packaging

| Materials | Glass, Plastics, Metal |

| Shapes | Cylindrical,square, hexagonal, oval complex shapes... |

| Content | 20ml - 1L |

| Product diameter | 35 to 95 mm |

| Product height | 90 to 200 mm |

Sleeves

| Functionalities | Tamper evidence |

| Type of films | PET, RPET, OPS |

| Films thickness | from 50 à 75 microns |

| Finishing | neutral, printed... |