A path forward PET closed-loop recycling: Crystal Wash®

To support brands in their ecological transition, we have developed an offer dedicated to the recycling of primary packaging, with shrink-sleeve labels and equipment solutions designed for each material and adapted to the recycling streams of different markets and countries.

A crystallizable shrink-sleeve label for closed-loop PET recycling

An innovation dedicated to bottle-to-bottle PET recycling

Our Crystal Wash® sustainable label sleeving solution offers to PET packaging the full body decoration benefits, in terms of premium decoration and maximized communication surface, for any packaging shape, whilst ensuring their bottle-to-bottle recycling. Compatible with the closed-loop clear PET recycling process in North America, this crystallizable shrink-sleeve label will be 100% recycled with the PET packaging allowing the of new r-PET packagings.

It is a good example for our ‘Path Forward Recycling’ approach under which we develop innovative shrink-sleeve and machinery technologies to promote primary packaging recycling.

Approved and recommended by APR

Our sustainable sleeve label Crystal Wash®, is approved and recognized by APR (Association of Plastic Recyclers), the major recyclers’ Association in the USA.

Furthermore, this eco-friendly shrink-sleeve label is in compliance with American PET recyclability practices, to guarantee the closed-loop bottle-to-bottle recycling of PET containers.

It enables recycling of CRYSTAL WASH® shrink-sleeve along with the PET bottles without the need of separating bottles and shrink-sleeve before. The sleeved bottles are grinded resulting in a mixture of PET bottle material and printed PET shrink-sleeve material which is washed in a hot caustic (alkali) washing step.

During washing step, the ink washes off and leaves the clear substrate but does not contaminate the wash water nor the PET film meeting requirements of APR testing protocol.

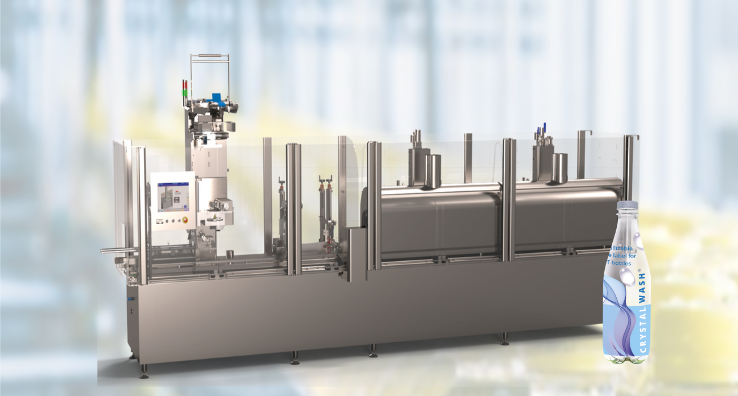

A shrink-sleeve equipment offer to apply our sustainable label

To implement our CRYSTAL WASH® sustainable label solution on your products, we offer a range of equipment designed to fit with this crystallized PET film’s characteristics such as adapting the steam shrinking technology for the soft drinks, home and personal care products.

Those flexible and modular Machines adjust to your packaging specifications, to accompany you on your ecological transition by integrating your products in a circular economy flow.

All of them are equipped with energy consumption optimization systems, to reduce your carbon footprint.