The light-blocking protection compatible with clear PET recycling

Brands using sensitive products face several challenges: protecting their products from light, ensuring the recyclability of their packaging, and strengthening their brand identity.

How to reconcile these issues of protection, eco-design and image?

The light barrier shrink-sleeve label for your recyclable packaging in clear PET

LDPET® White Barrier, the light-blocking protection for your sensitive products, compatible with PET recycling

HDPE and opaque PET packaging do not meet the requirements of recycling flows: only clear PET containers allow closed-loop recycling. LDPET, a full-body shrink-sleeve label compatible with the recycling of clear PET, has been a recognized and proven in the beverage market for over 15 years.

It is now enriched with a light-blocking function to meet the specific needs of light-sensitive liquid food products:

- Light blocking with a transmission < 1%.

- Preservation of organoleptic properties: taste, color, vitamin content

- Increases the shelf life of products

Brands can reconcile recyclability, product quality and shelf visibility.

A reinforced brand identity

By choosing PET, brands can optimize their packaging costs by eliminating the aluminum seal and reducing the weight of the bottles. They can also develop a bottle shape to reinforce their uniqueness and increase differentiation at point of sale.

The LDPET White Barrier offers a full 360° decoration over the full height of the product. Its exceptional whiteness and opacity give it a premium character, and the printing technologies offering up to 10 colors allow a qualitative reproduction of the artwork.

High-performance, low-consumption equipment to reduce the carbon footprint of products

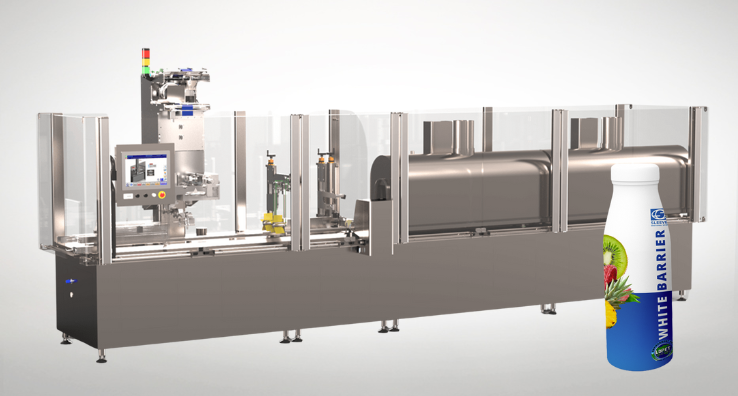

For the implementation of LDPET White Barrier, we have developed flexible equipment, which can handle several types of films: low density (LDPET, LDPET White Barrier), PET, PE/PP...

They are adapted to the characteristics of the liquid food markets, to operate in a wet environment, at medium and high speeds. Their modular design fits your specifications and the features of your packaging lines.

An energy consumption adjusted by format, allowing to reduce the carbon footprint of your products.

Protection and differentiation without compromising on recyclability

Click on the packaging to discover our offer