A micro-line for short production chain and direct distribution in dairy markets.

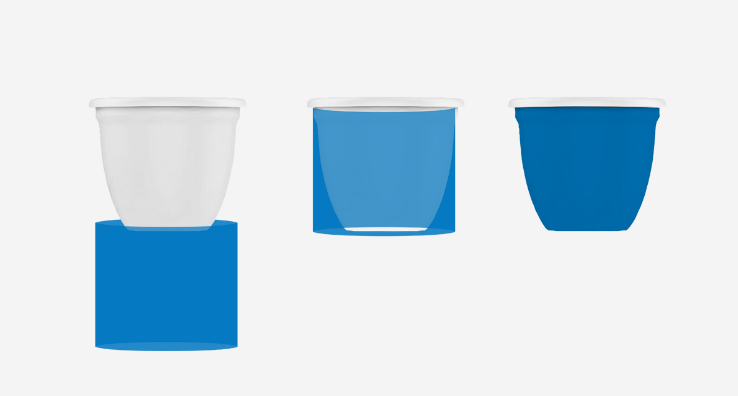

- A system offer: with eco-designed sleeves for recycling HDPE/PET pots and bottles

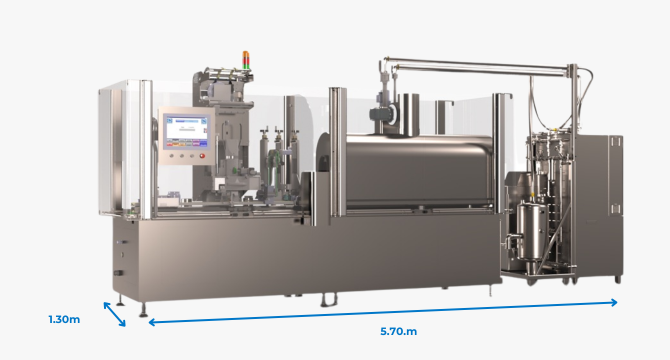

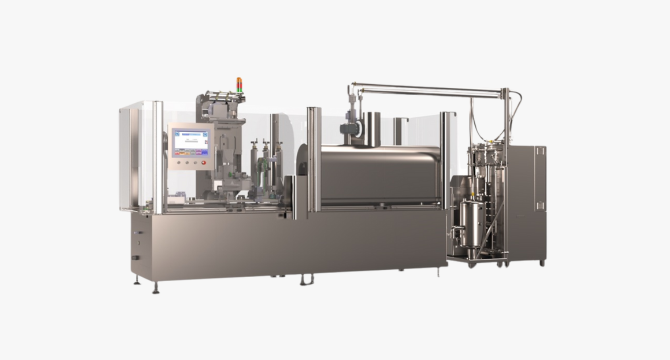

- An all-in-one modular equipment with optimized footprint and integrated steam generator

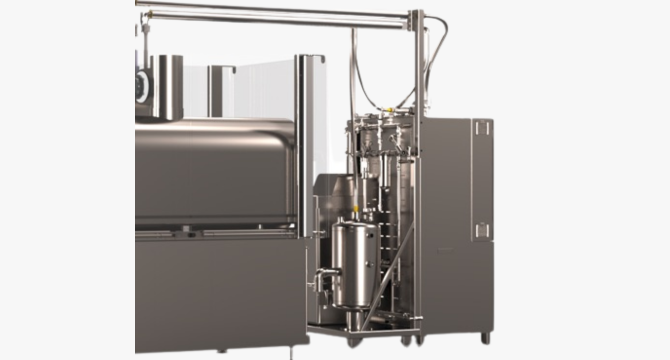

- An integrated steam generator with its water treatment to optimize energy consumption

- A multi-format design, fully configurable with HMI to ensure changes in less than 10 minutes

Features

An equipment that aligns with the eco-design of the products

A compact all-stainless steel monobloc structure integrating: dryer, application head, shrink tunnel, electrical cabinets integrated into the frame, and a steam generator. The modular design enables the handling of a wide range of products, from jars to bottles, in PET and HDPE, with multiple capacities and shapes.

Ease of implementation for various shapes.

Designed with modularity in mind, this machine accommodates various product formats. Tooling is designed for easy, tool-free, and adjustment-free interchangeability. Operators have complete autonomy and can change formats within minutes, assisted by a central HMI and tutorials accessible via QR codes.

Steam shrink tunnel with controlled consumption.

The steam shrink tunnel, with its unique and innovative design, ensures optimized energy consumption through the combination of three key elements: a lift system, a range of steam diffusers, and an expansion chamber tailored to each product, all managed centrally from the 12-inch HMI.

Minimizing carbon footprint.

Integration of the steam module along with its water treatment system:

- Optimizing energy flows (condensate recycling)

- Format-specific settings (energy reduction)

- Maximum consumption < 60% compared to existing market standards

Options

Multi-controls to ensure product quality.

A module of inline control, integrated into the monobloc structure before the shrink chamber, provides a reliable and effective solution with its multi-controls. Flexible, it adapts to the various shapes and materials of your packaging.

Tool carriage for your various formats.

An ergonomic tool carriage, lightweight and easy to move, specially designed to store your tools and keep them readily available next to the equipment. It reduces downtime during format changes. Tools are protected when not in use and during transportation.

Marking and serialization module as an external component to the equipment.

The marking is positioned in the warehouse, as an external module to the equipment for easy and quick access. It allows for various forms of marking or coding to meet traceability and serialization needs: printing of DLC (Date of Last Consumption), barcode, batch number, and various product information. Several printing technologies are available: inkjet, laser, etc., adapting to the line speeds of the markets.

Specifications

Machine

| Conveyor height | 980 +/- 50 mm |

| Speed | 500 bpm |

| Cutting diameter | 100 mm |

| Steam consumption | 200 Kg/h |

| Steam pressure | 6 - 8 bars |

| Electrical consumption | 12 kW |

| Machine length | 6400 mm |

Packaging

| Materials | PET, HDPE (PP, glass possible) |

| Shapes | Cylindrical, oval, advanced |

| Products diameter | 35 to 128 mm (jars, bottles) |

| Products height | 245 mm |

| Sizes | 80g to 800g - 20cl to 75cl |

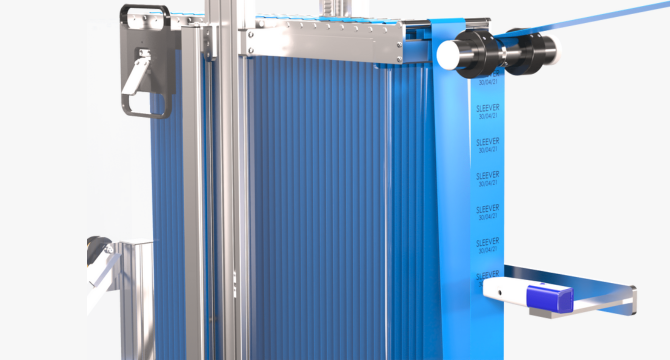

Sleeves

| Applications | Full body, partial sleeve |

| Type of films | TPEG, PET |

| Films thickness | 50 - 65 microns |