Carafes, glass bottles, special packaging, secure your products

- Controlled flexibility of multi-format for alcohol manufacturers: the guarantee of quick format changes

- Gerer of bottles with multiple and varied shapes and materials

- Precision processing for an excellent finish

- Ergonomics of the line at the service of the operator

Features

A technology at the service of the diversity of shapes and materials of your bottles

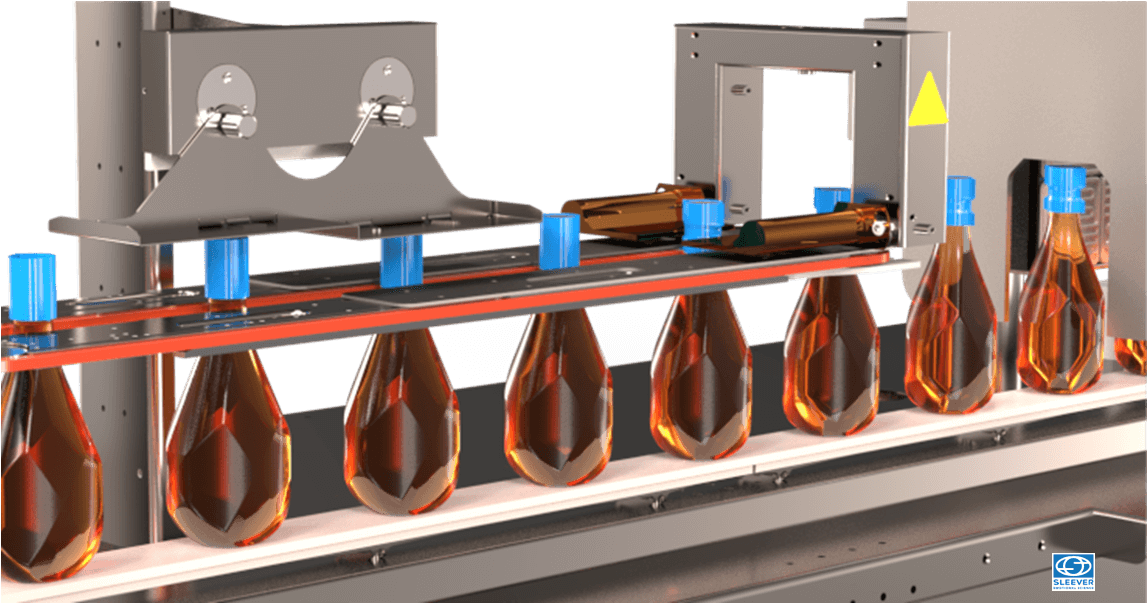

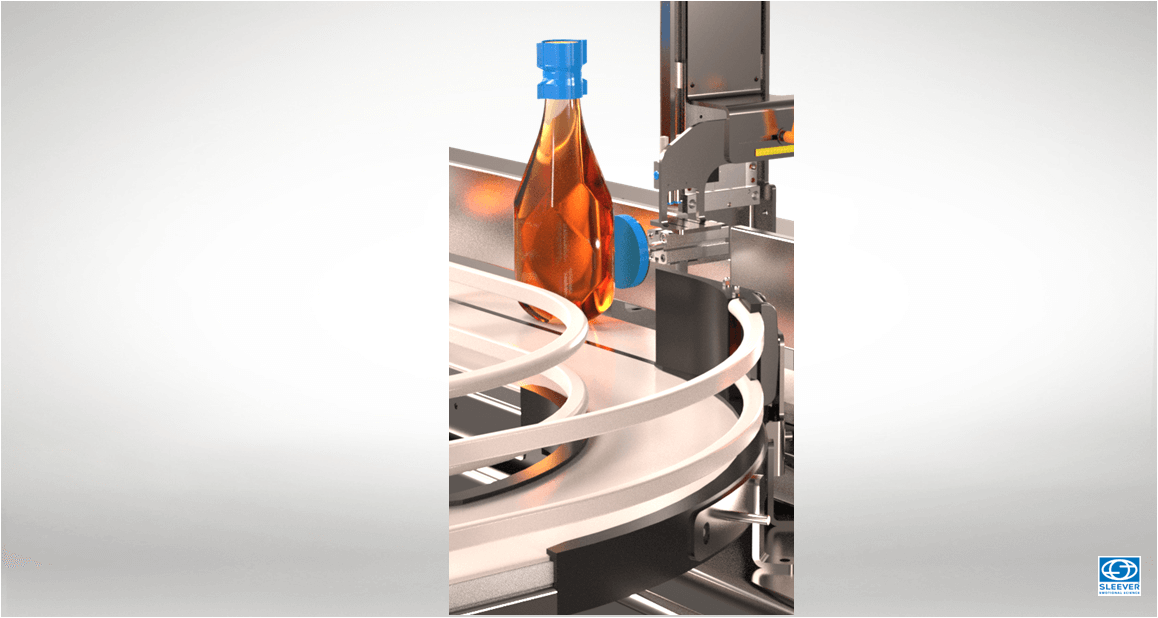

An equipment designed according to the constraints of the products of the alcohol and spirits market. The guides and tooling parts (screws, stars, etc.) are used to accompany the decanter or bottle along the entire product path. They are non-abrasive so as not to damage the label and the packaging. The height of the head can be adjusted to fit the different formats with care.

Tooling designed for delicate products with high added value, and reduced line downtime during format changes

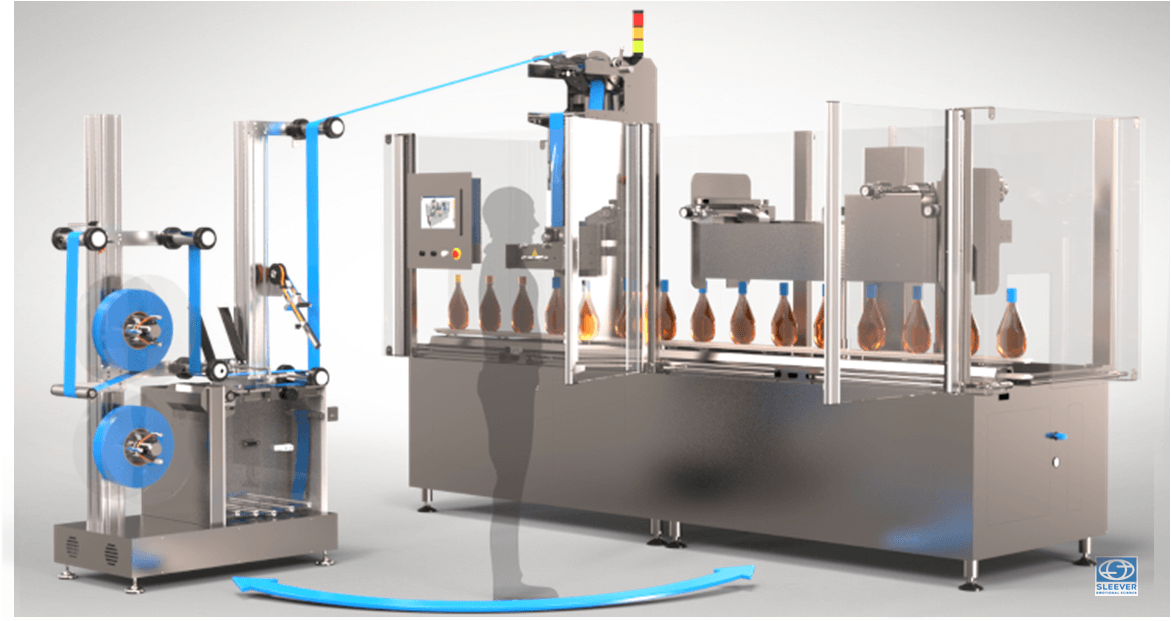

This compact machine offers quick access to tooling for a changeover time of less than 10 minutes. Interchangeable quick-fit modules, with one direction of installation, require no tools for set-up. This design allows for a multitude of formats to be accommodated and managed, more than 20 if necessary. This flexibility perfectly meets the expectations of alcohol producers who manage a multiplicity of decanters or bottles. The whole system allows to increase your productivity by optimizing the line stops.

Precise installation for tamper-proof opening

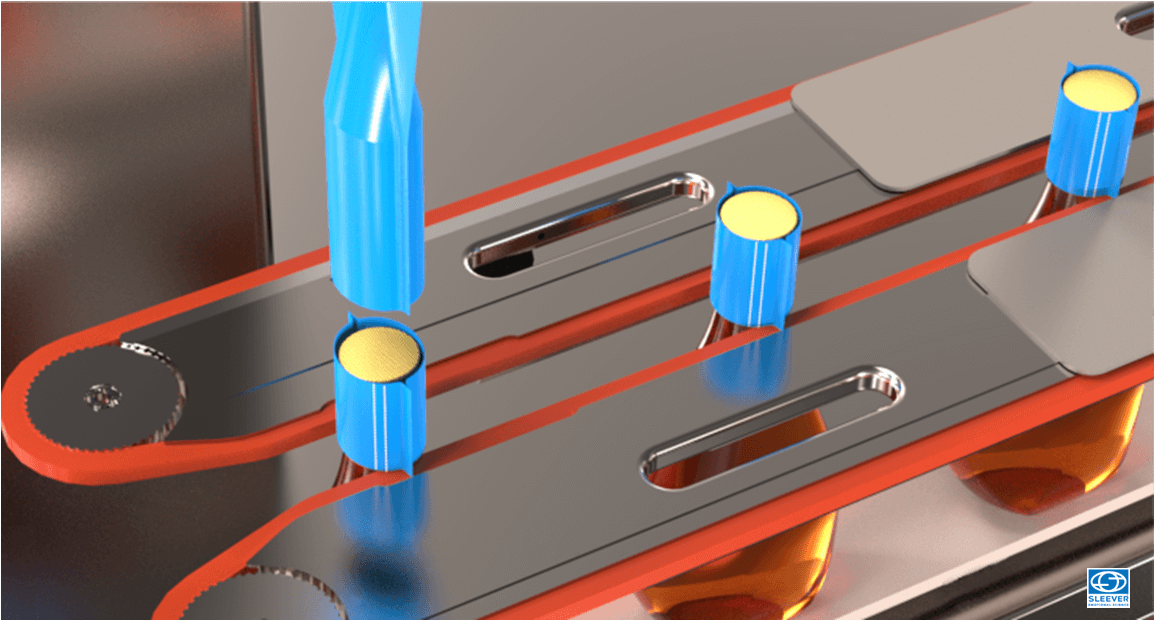

A belt module allows the shrink-sleeve to be placed at the desired height on the bottle. Once transferred, a device called cyclic jogger confirms its orientation and position with precision. Hot air nozzles located at the end of the belts fix the tamper-evident shrink-sleeve on the bottle to allow its transfer to the shrink tunnel.

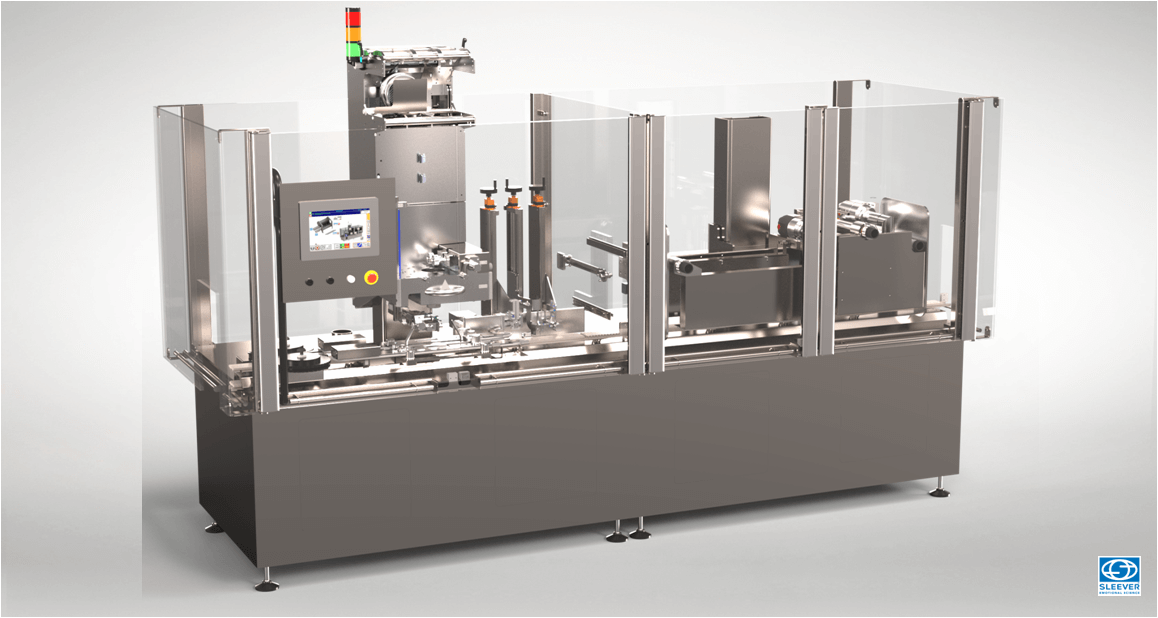

An ergonomic machine dedicated to the operator's comfort

This machine is designed for the operator, with transparent doors for a perfect visibility of the equipment in production. The graphic and interactive interface on a large touch screen makes it easy to control. The 90° oriented feeder magazine allows easy access to the coils located at man height and includes a splicing table for fast and error-free coil splicing. The shrink tunnel up/down system provides unobstructed access in the upper position for cleaning or line emptying.

Options

Multiple controls to ensure precision tampering

This one meter long module gathers all the detection cells and a pneumatic cylinder ensuring the delicate ejection of the products on a parallel conveyor. The defects have been previously recorded and parameterized in the automaton.

The orientation of the sleeve to ensure the correct positioning of the break-in guarantee

This module allows the shrink-sleeve folds to be positioned perpendicular to the belts. The shrink-sleeve label cannot slip between the product and the belts during its descent, which guarantees its correct positioning when placed on the product.

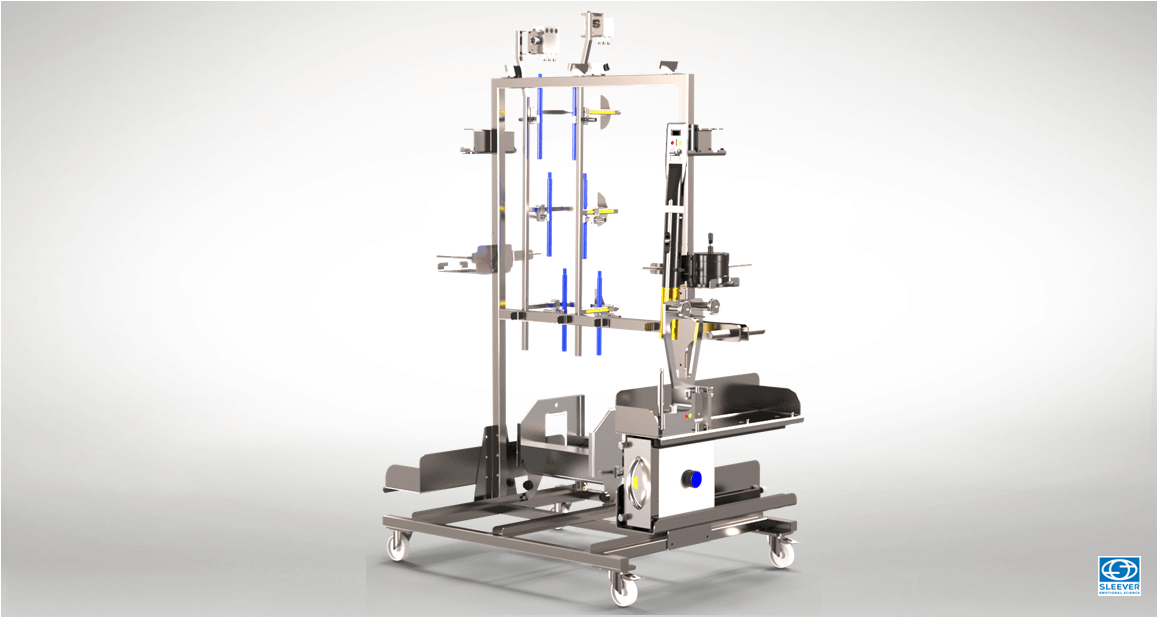

Mobile tool carriage for a variety of formats

This ergonomic, easy-to-move cart is designed to store 4 tools and keep them at the operator's disposal, next to the machine. It reduces downtime during format changes and ensures less downtime for your line. It also allows to protect the tools when they are not used and when moving.

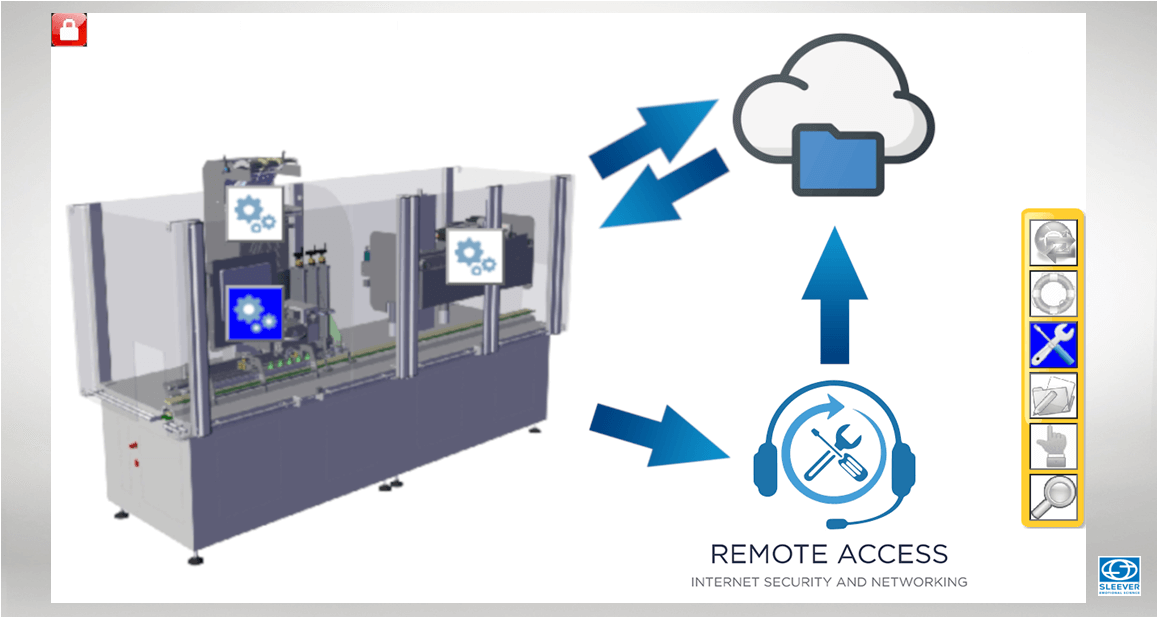

Ethernet module for performance improvement

This module exchanges data between the equipment and the line supervision system. The production data feedback will allow to optimize the equipment settings and to improve its performance. It can also be used to communicate with other machines upstream and downstream for the regulation of the packaging line.

Specifications

Machine

| Hauteur convoyeur | 980 +/- 50 mm |

| Cadence | 80 à 400 cpm |

| Diamètre de coupe | 100 mm |

| Consommation électrique | 24 kW |

Packaging

| Emballages | verre , métal |

| Formes | cylindrique , carré , complexe |

| Contenance | de 20ml à 1,5l |

| Diamètre produit | de 35 à 135 mm |

| Hauteur produit | de 90 à 300 mm |

Sleeves

| Fonctionnalité | Inviolabilité |

| Type de film | PET, RPET, OPS |

| Epaisseur de film | de 50 à 75 microns |