Tamper evidence for small food formats and household products

- A horizontal application adapted to unstable packages, small formats and sophisticated and varied shapes

- Total tamper resistance with protection and security features

- An ergonomic design for frequent and quick format changes

- A combination of performance and quality finish

Features

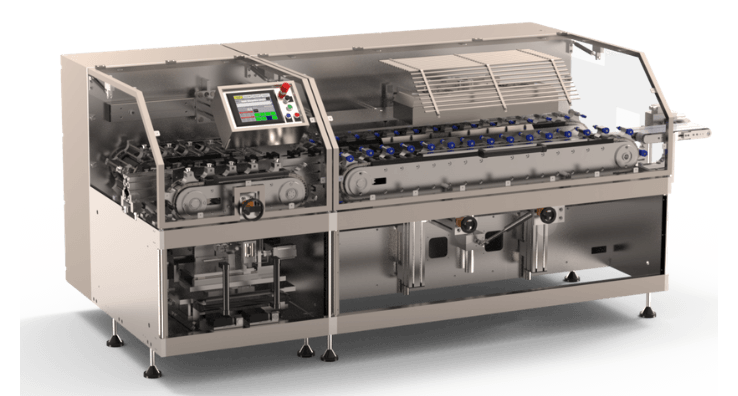

An ultra-compact machine specifically adapted to the small and unstable formats of confectionery and household items

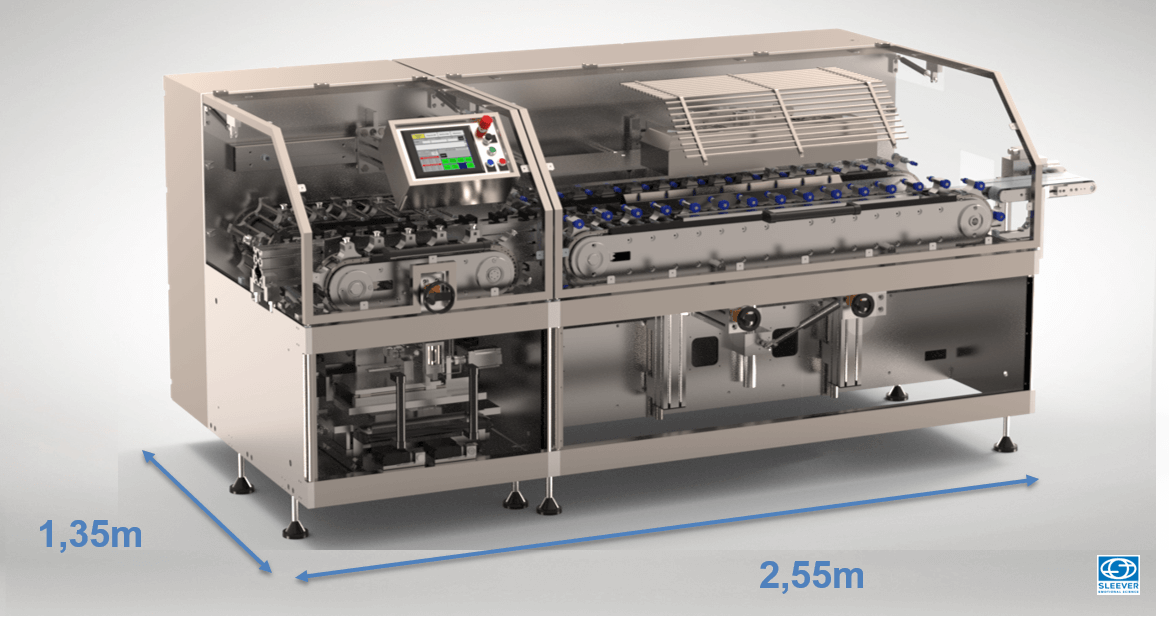

Its design and horizontal application technology meet the security needs of confectionery, DIY and homeware brands for their small and unstable formats. Its very compact size, less than 7 feet long, allows for optimal floor space and fits into any workshop. It consists of a single chassis and includes the horizontal application, the infrared/hot air shrinkage applicator and the integrated electrical cabinet.

Increased security thanks to full product protection

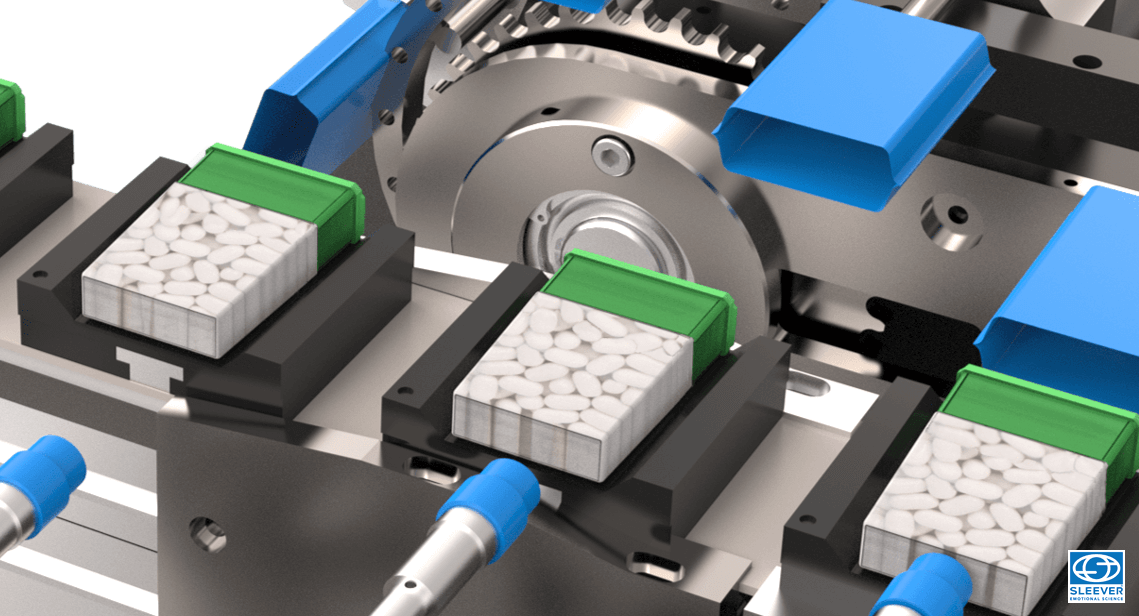

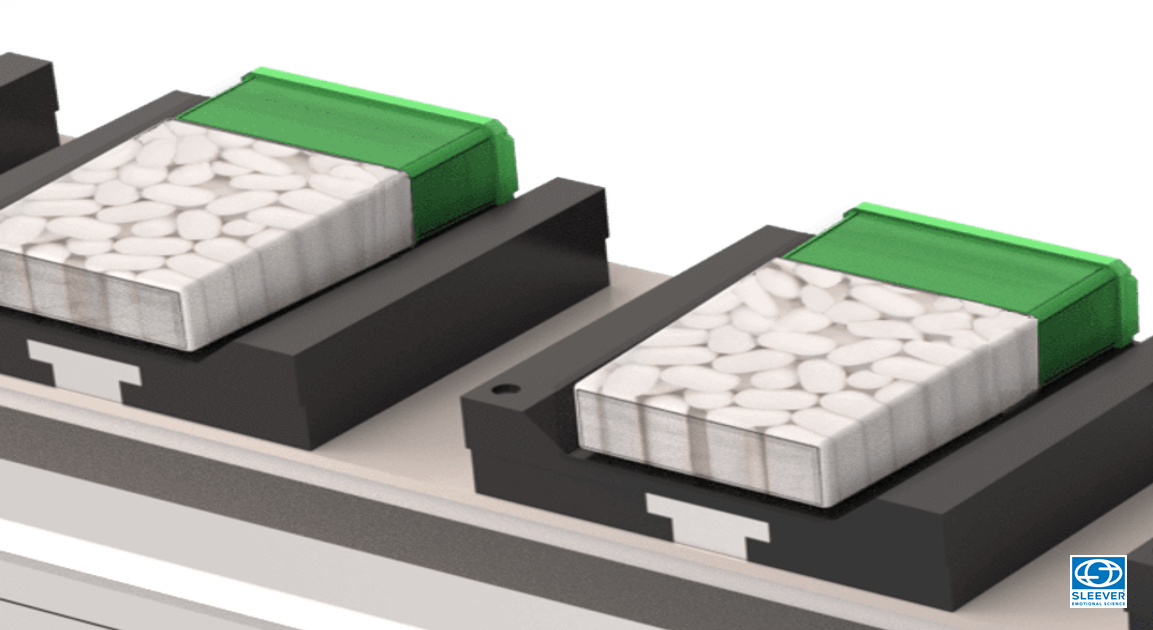

During the application process, the product is fed flat onto a closed-cells conveyor where it is maintained regardless of the complexity of its shape or the speed of the machine: after transferring it to the inside of the shrink-sleeve, it is fully wrapped for complete protection and enhanced security.

An ergonomic design for easy changeovers

Everything has been designed to promote flexibility and optimize format changeover times, which are common in the confectionery and object markets. Each format has its own toolkit that can be replaced without any tools, such as the retractable honeycomb blocks on the conveyor. The settings are stored in the PLC and memorized on the interface, which makes the operator's work easier. Changes can be made in just a few minutes and the restart is immediate. Ergonomics is ensured by easy access to every part of the machine.

A technology that does not compromise on speed while ensuring a quality finish

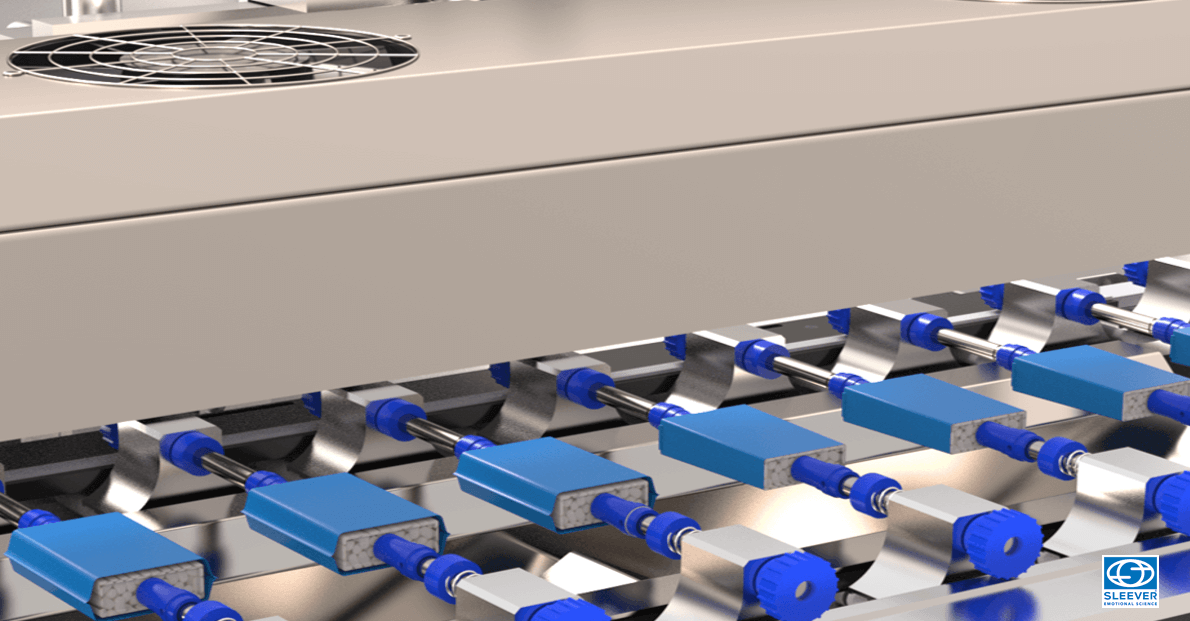

The quality of the finish is guaranteed thanks to a gripping system that keeps the products rotating while continuously advancing under the infra-red ramp ensuring the shrinkage of the shrink-sleeve label: in this way, the product is not in contact with the conveyor at any time and therefore avoids any risk of damage. This technology combines quality with high speed up to 130 cpm.

Options

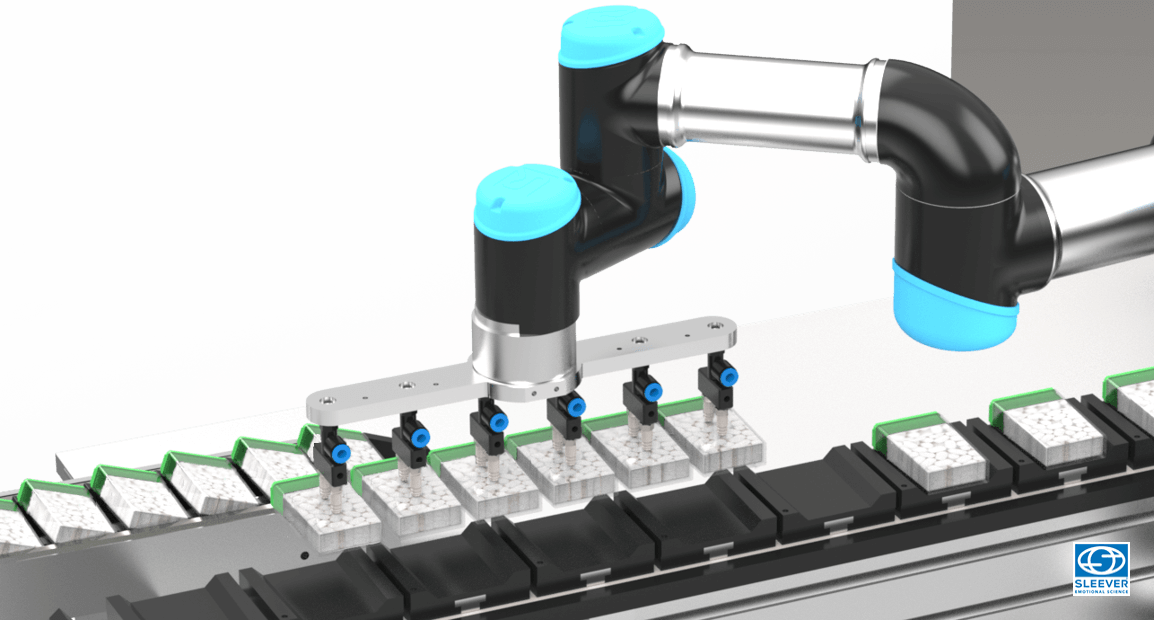

Automatic loading: a tailored solution for your performance

This module allows the products to be directly loaded on the conveyor and frees up an operator station assigned to this function. This system brings reliability and perfect repeatability throughout production.

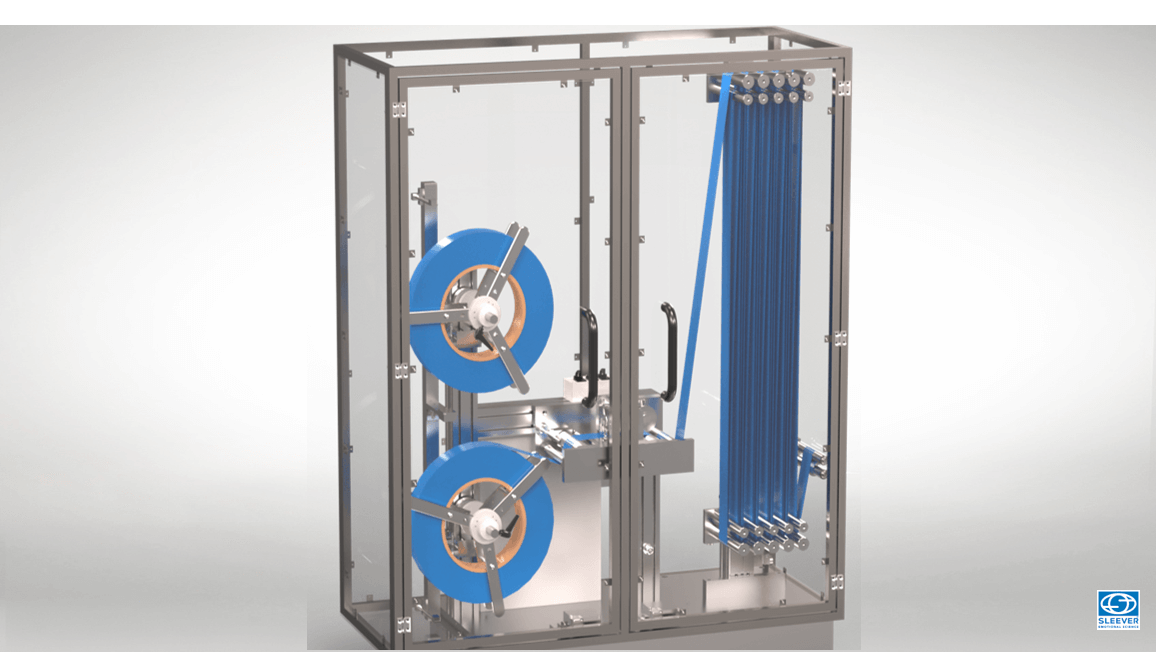

Large capacity unwind unit for increased autonomy

This large capacity unwind unit offers the machine greater autonomy, thus freeing up time between two reel splices, an operation that is made easier and safer with the splicing table. Time saved and efficiency guaranteed for your operators!

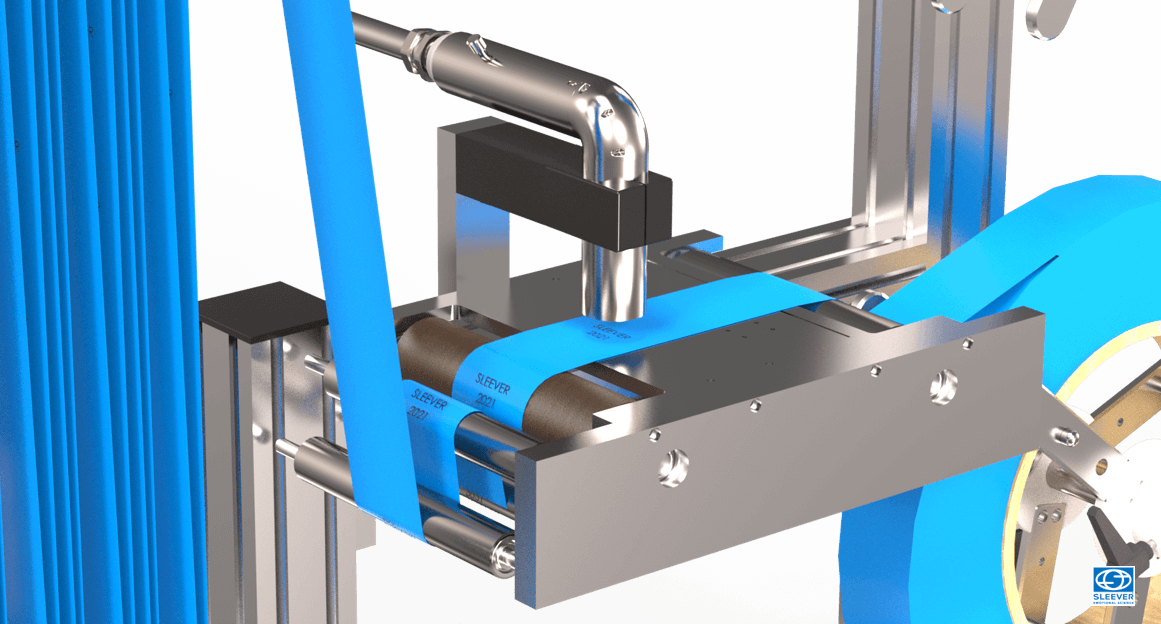

Ensure the traceability and serialization of your products

Multiple solutions ensure the traceability of your products and meet the regulatory requirements and identification needs of your products. Different printing technologies (laser, inkjet, thermal transfer) and coding types (alpha-numeric, barcode and datamatrix) are available, depending on your product specifications.

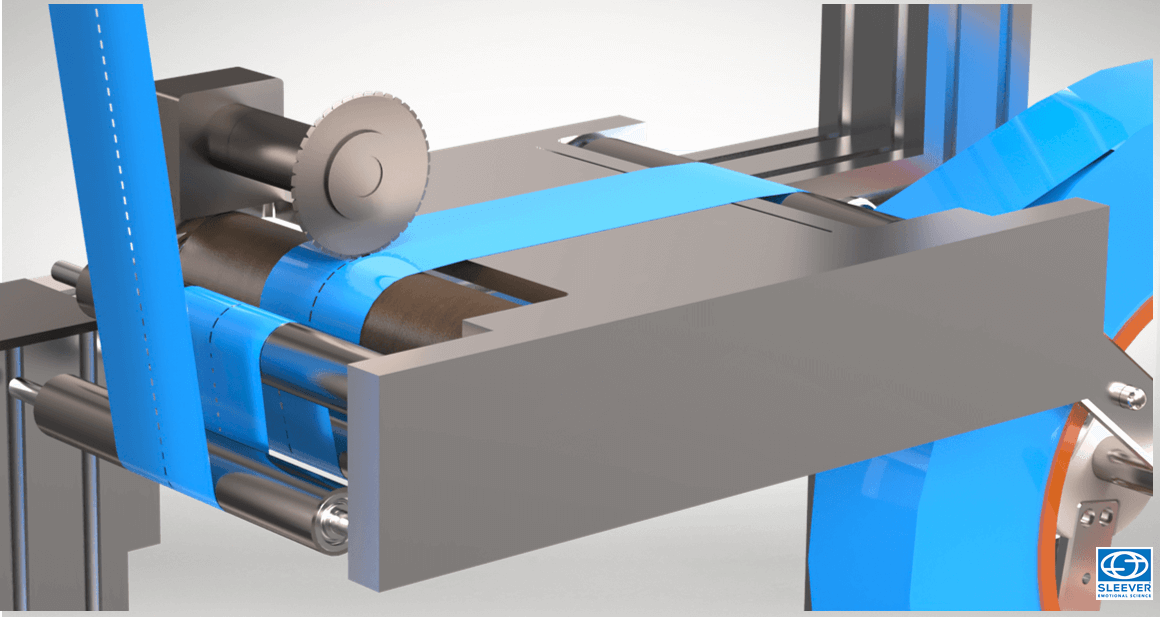

In-line micro-perforation for increased flexibility and consistent quality

By allowing you to choose the type of opening for your shrink-sleeve label, depending on the type of tamper evidence you are looking for, in-line micro-perforation gives you flexibility and a high level of quality, regardless of the type of shrink-sleeve or the shape of your product.

Specifications

Machine

| Conveyor height | 960mm |

| Speed | 130 cpm |

| Compressed air | 6 bars |

| Electrical consumption | 20 kW/h |

| Machine length | 2540 mm |

Packaging

| Material | Objects , plastics, metal |

| Shapes | Cylindrical,square, hexagonal, oval complex shapes... |

| Product diameter | 4-30 mm |

| Product length | 65-150 mm |

Sleeves

| Applications | Tamper evidence |

| Films | PET, RPET, OPS |

| Film thickness | 40 to 50 microns |

| Finishing | Neutral , printed,... |