Flip top caps capsules: Ensuring turnkey security

- The solution for brand's partners in the hygiene, personal care and parapharmacy markets

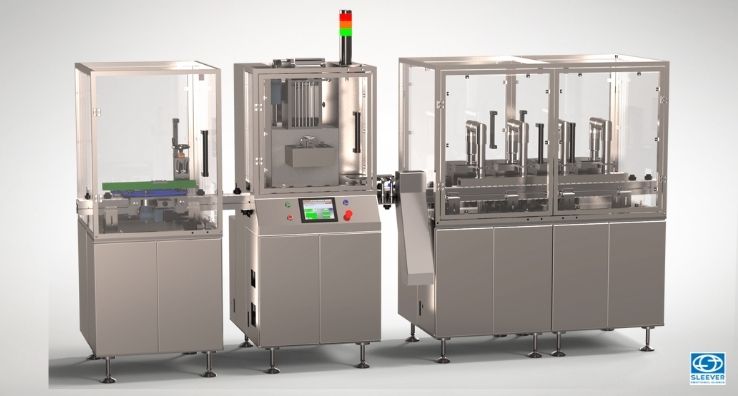

- Compact and modular equipment adapted to your production' specifications and the use of new films with 30% rPET.

- Precise and optimal label application to guarantee the correct placement of the tamper-evident band

- A quality control system that allows you to obtain a zero defect at the end of production.

Features

Modularity and flexibility at the service of security

The combination of different modules allows you to manage your range of formats and to make quick changes without requiring massive tooling. This technology allows the use of different types of films, and especially our shrink-sleeve label products with 30% r-PET to meet environmental legislations.

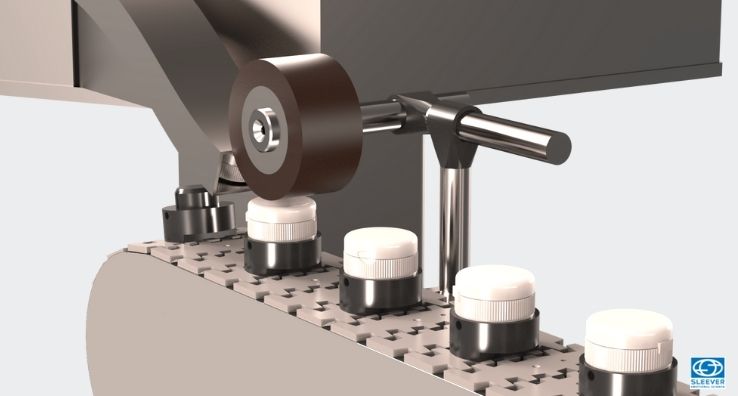

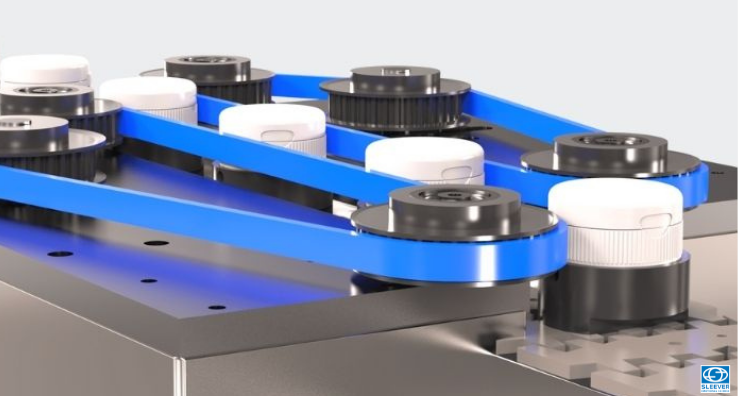

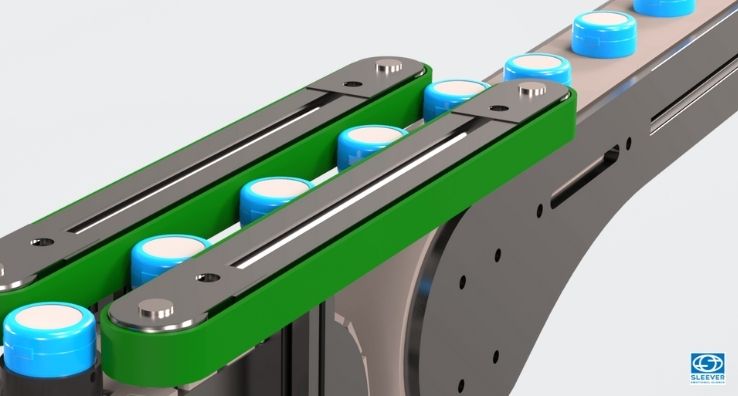

For a perfect orientation of the products

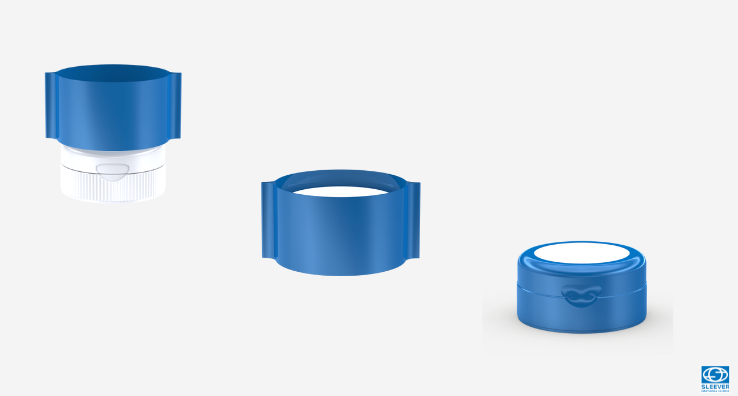

The orientation module always positions the flip top caps in the same direction, perpendicular to the shrink-sleeve opening system. This accurate positioning ensures that the cap is secured after shrinking.

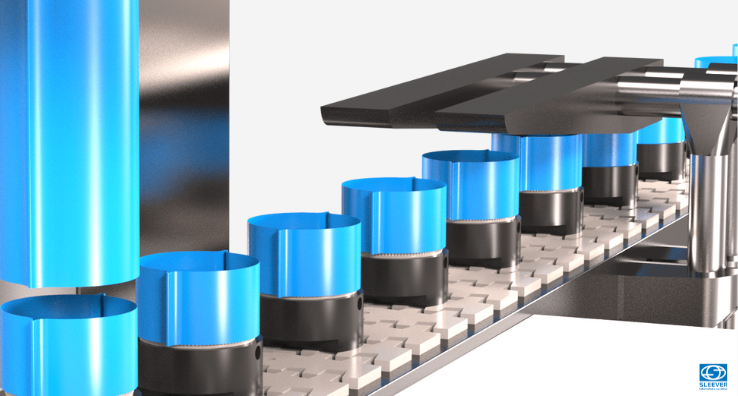

Precise Label positioning to ensure security

The combination of a shrink-sleeve referencing module and the design of the pad on the conveyor ensures the precise full-body (top and bottom) covering of the shrink-sleeve on the cap.

The guarantee of a secure product at the machine exit

Each stage of the production process is subject to precise control to ensure zero defects at the machine output. Thus, the placing and orientation of the cap, the placing of the shrink-sleeve label and the positioning after the sleeve' shrinking are checked.

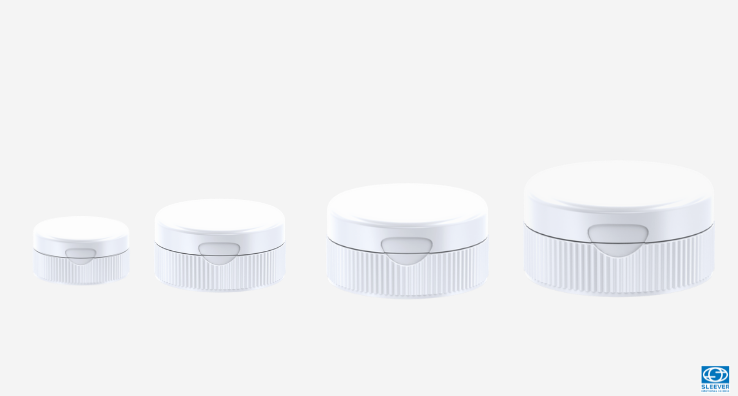

The security solution that meets the specifications of flip top caps' manufacturers

A complete technical offer to guarantee the security of a flip top cap by loading, orienting the cap, fitting and shrinking a shrink-sleeve label with a micro-perforation. A solution with a high degree of autonomy to meet the speed of the packaging lines.

Options

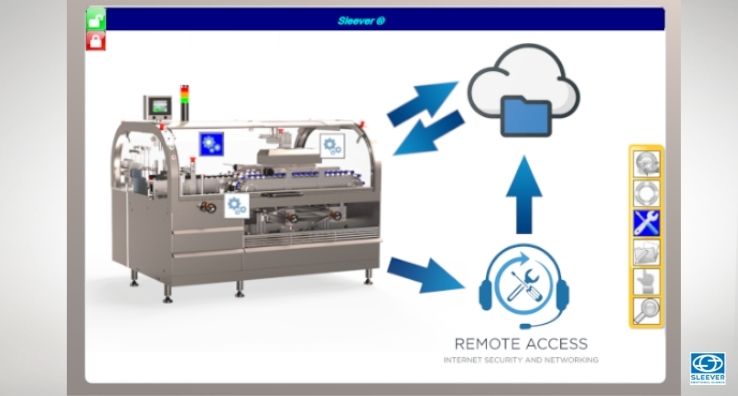

Interactivity at the service of performance

The VPN connection allows a greater opening up to the outside world and authorizes remote assistance, for diagnosis and remote intervention if necessary. A solution that saves time and optimizes travel costs for certain interventions.

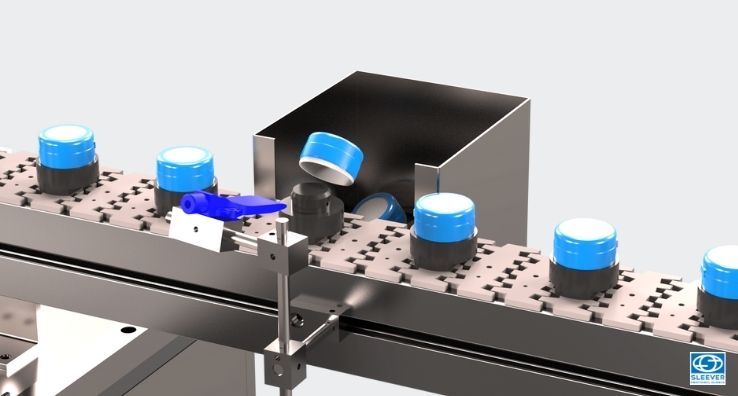

An easy transfer for your end of line operations

Taking advantage of a turnkey solution means taking advantage of the expertise offered to provide all the modules specific to your market. In this case, the transfer module allows you to switch from a pad conveyor to a standard conveyor to ensure the transfer of the product to another end-of-line operation.

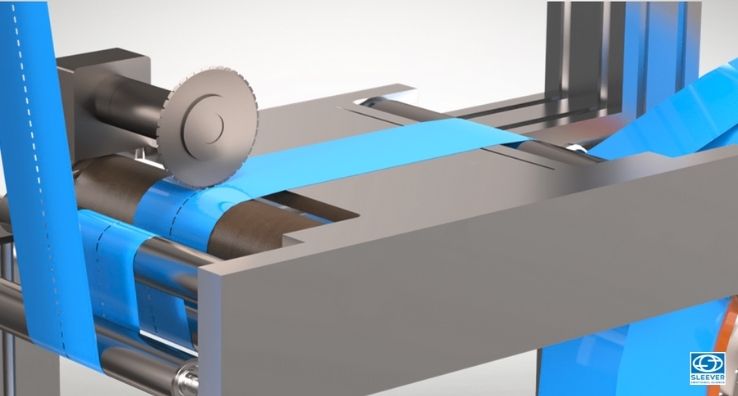

For an increased flexibility and quality assurance

By allowing you to choose the type of opening for your shrink-sleeve, and depending on the tamper-evident needs that you are looking for, an in-line micro-perforation Module offers you a great level of flexibility and quality, regardless of the type of shrink-sleeve or the shape of your product.

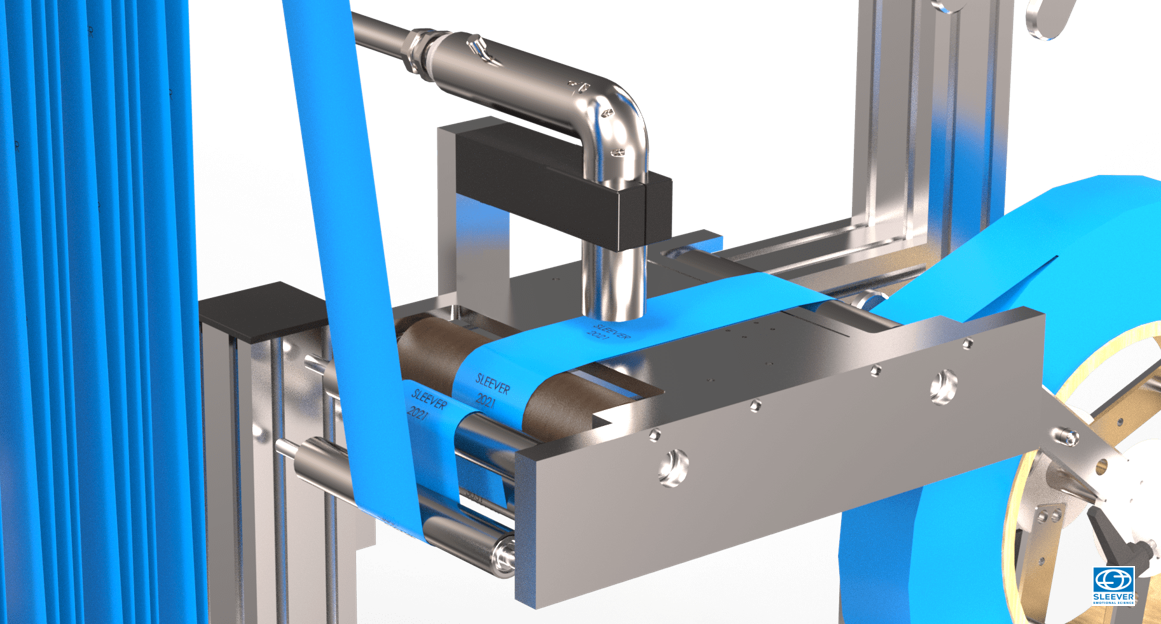

Ensure the traceability and serialization of your products

Multiple solutions ensure the traceability of your products and allow to meet the regulatory requirements and identification needs of your products.

Different printing technologies (laser, inkjet, thermal transfer) and coding types (alpha-numeric, barcode or datamatrix) are available according to your products' specifications.

Specifications

Machines

| Hauteur de convoyeur: | 980 mm +/- 50mm |

| Cadence: | 200 cpm |

| Diamètre de coupe: | 100 mm |

| Consommation électrique: | 20 kW/h |

| Machine length | 5610 mm |

Emballages

| Emballage: | PEHD,PP |

| Formes: | Cylindrique , carré, ... |

| Diamètre produit: | 30 à 50 mm |

| Hauteur produit: | 15 à 40 mm |

Sleeves

| Fonctionnalité: | Sécurisation |

| Type de films: | PET, rPET ... |

| Epaisseur de film: | 40 à 90 microns |

| Finition: | Neutre , imprimé, ... |