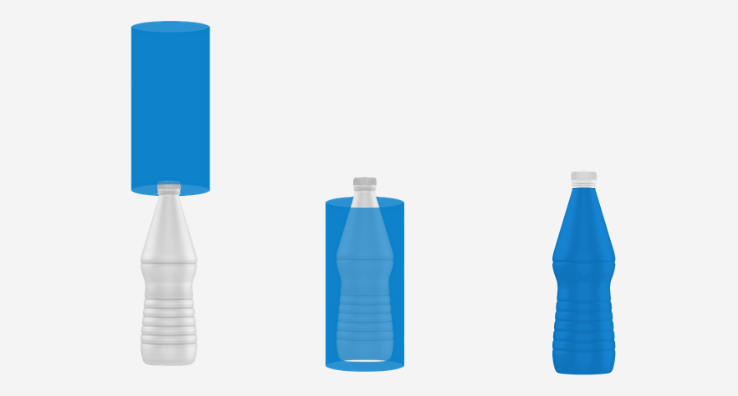

The equipment for the full body decoration of complex shapes' products

- A compact machine, which can be integrated into low speed packaging lines for the food, hygiene and cleaning products

- An operator-friendly graphic panel

- A modular and adjustable feeding system

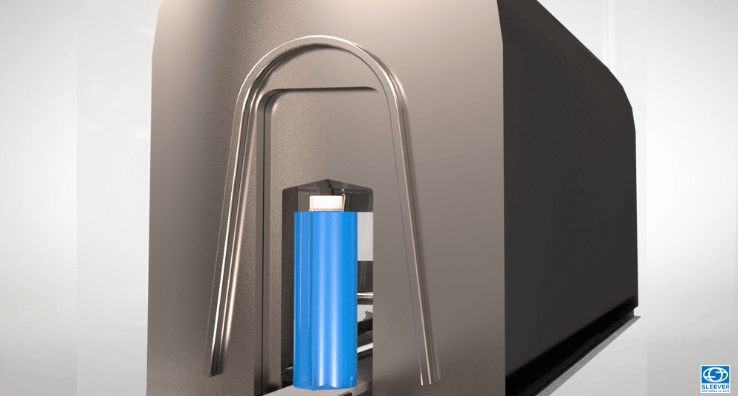

- A unique and innovative steam shrinking tunnel design

Features

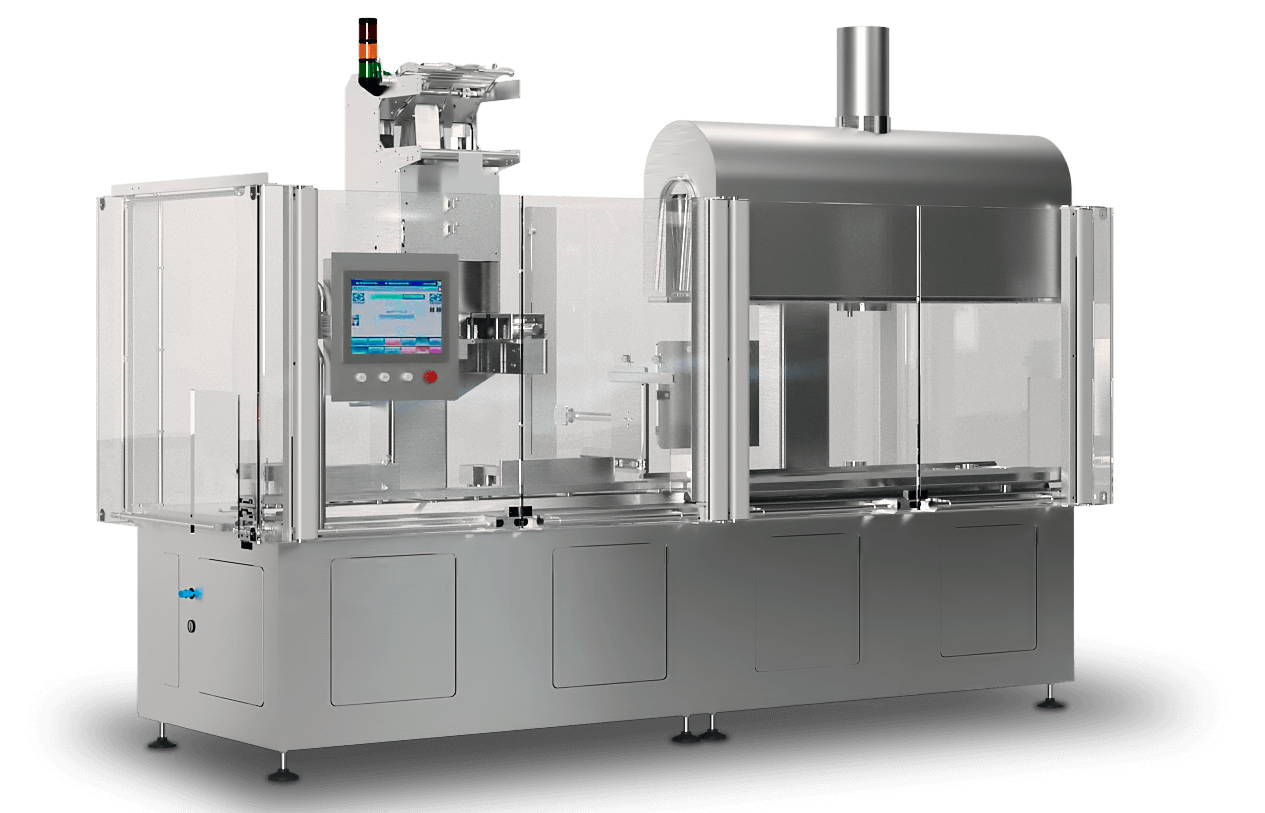

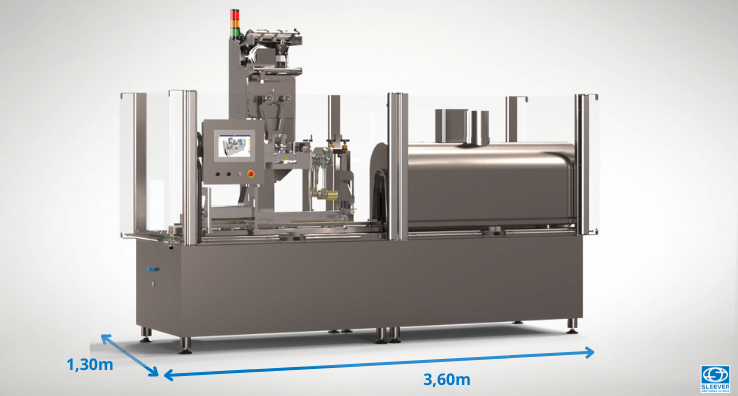

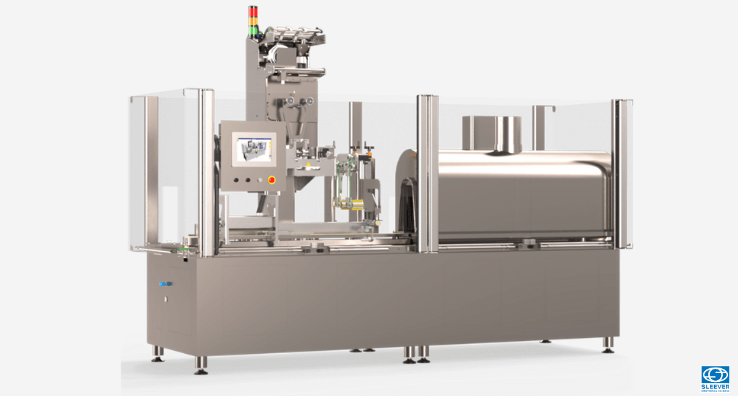

An ultra-compact, all-stainless steel machine with a 360° casing

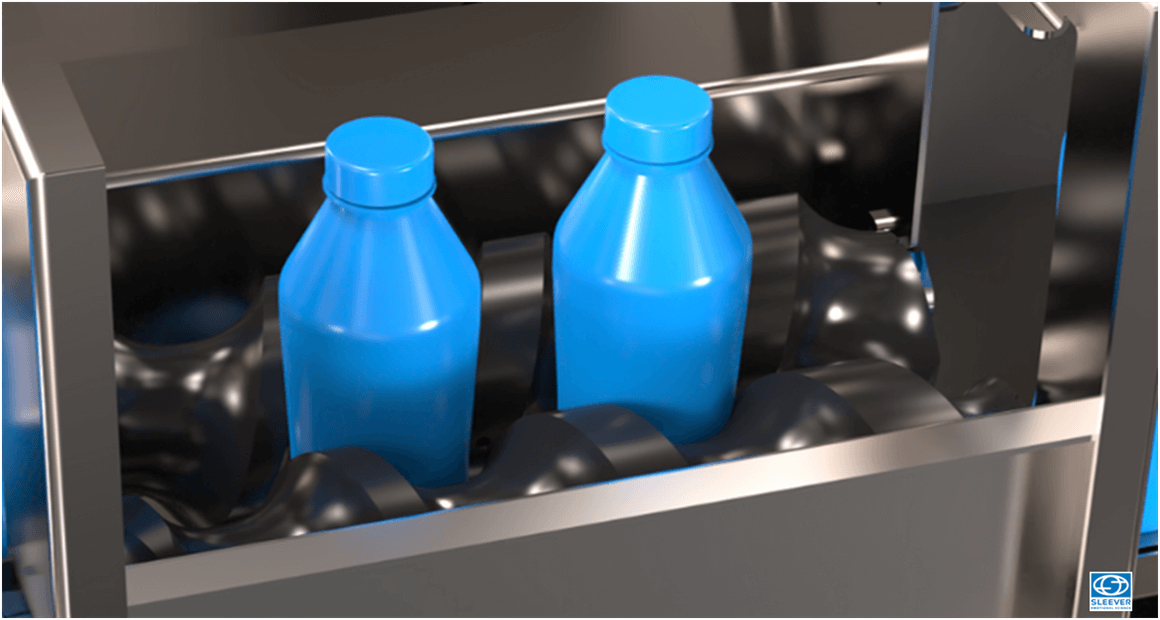

An all stainless steel monobloc structure offering an optimized footprint: it includes the applicator head, a shrink tunnel equipped with a height-adjustable system and the electrical cabinets. This machine meets the expectations of brands and subcontractors for the processing of full or empty packagings, from 50 ml to 2L, in plastic, glass or metal containers (aerosol, can, jar or bottle) to apply a Shrink Sleeve Decoration Label.

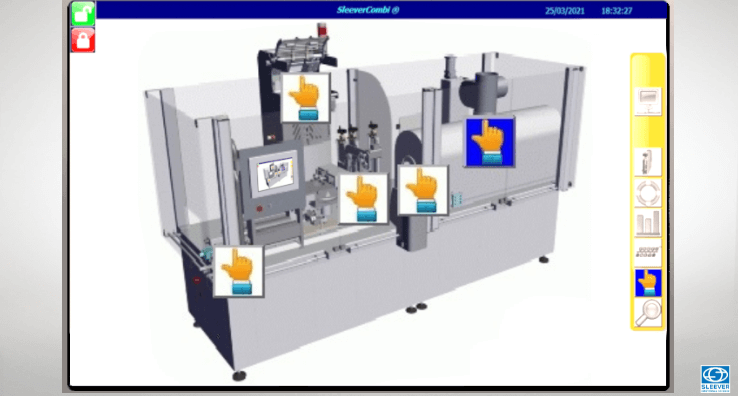

A large touch screen that makes it easy to understand and control the machine

The operator controls all the supervision functions throughout production with a large screen featuring a user-friendly graphic interface.

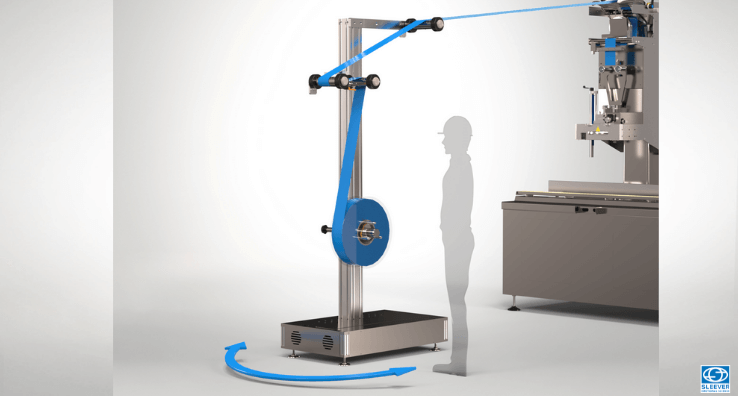

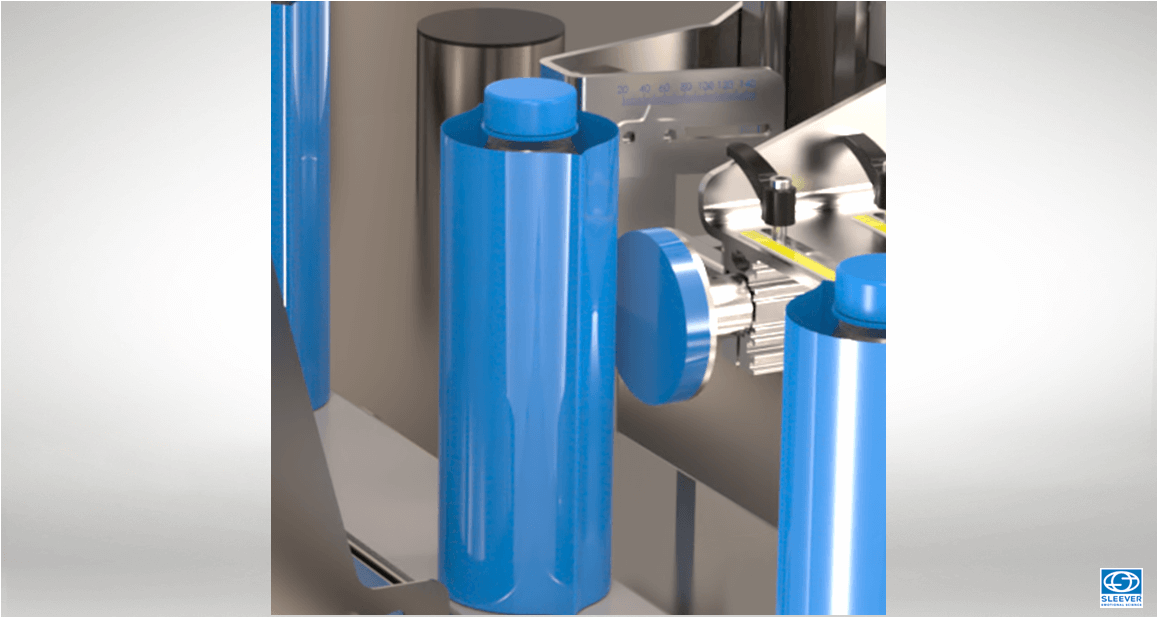

Easy access, orientation and multiple functions to suit your line

Operators have easy access to the loading station which is positioned at standard operator height. The shrink-sleeve unwind unit can be fully rotated for better ergonomics and can be upgraded to integrate optional features: splicing table, multi-reel holder, marking or micro-perforation...

Optimize your carbon footprint, control your energy consumption

The unique and innovative design of the steam shrink tunnel minimizes energy consumption through the combination of three key elements: a height -adjustable system, a steam diffusion system and an expansion chamber, all of which are sized for each format. This allows for a controlled and repeatable quality of finish.

Options

The modular machine for multi-formats

With its modular design, this machine can accommodate multiple product formats, offering easy changeovers without tools or adjustments. The operator is completely autonomous and can complete the changeover in a matter of minutes.

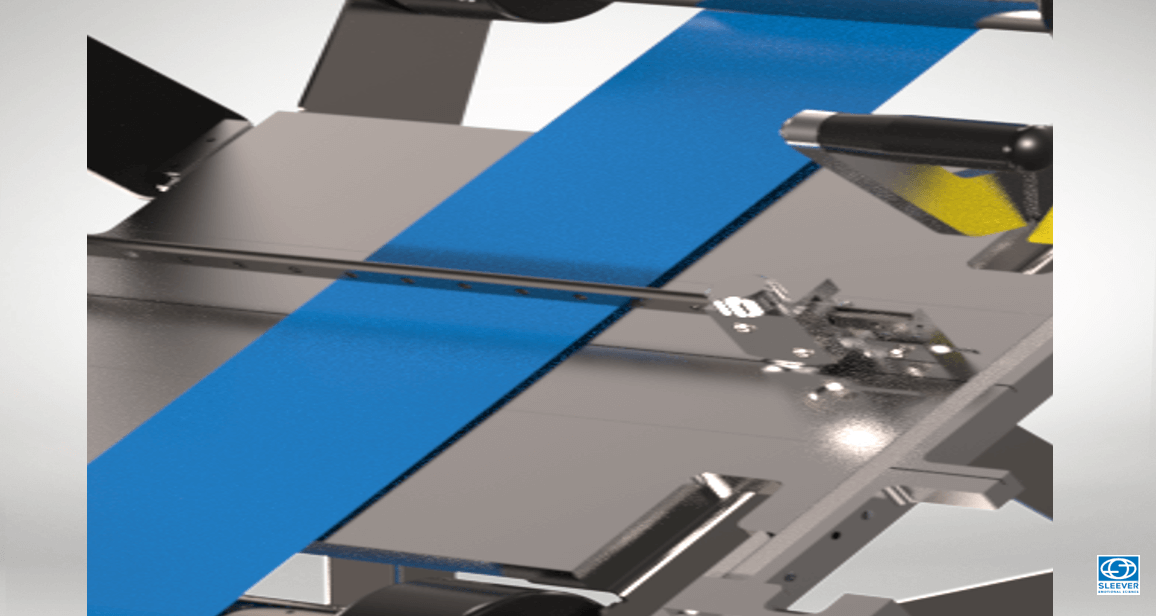

The quality of the reel splice is a key element of your productivity

When changing reels, the quality of the reel splice is a guarantee of productivity. The splicing table is equipped with a double locking system, a secure cutting tool, and an adhesive tape dispenser. This brings comfort and safety to your operator.

A guaranteed and constant level of quality

An inline control module integrated in the monobloc structure, before the shrink chamber, provides a reliable and efficient solution with its multi-check system. Very flexible, it also adapts to the multiple shapes and materials of your packaging.

Specifications

Machine

| Conveyor height | 980 +/- 50 mm |

| Speed | 80 - 150 bpm |

| Cutting diameter | 100 mm - 130 mm |

| Steam consumption | From 50 to 150 kg/h |

| Steam pressure | 6 - 8 bars |

| Electrical consumption | 9 kW/h |

| Machine length | 3600 mm |

Packaging

| Materials | Glass, Plastics, Metal |

| Shapes | Cylindrical, oval, square, complex shapes |

| Sizes | 100 ml to 2L |

| Products diameter | 35 to 128 mm |

| Products height | 35 to 300 mm |

Sleeves

| fonctionnalité | Habillage intégral |

| Type of films | PET, RPET ... |

| Films thickness | 40 to 90 microns |

| Finishing | Neutral, printed effects, opaque... |