Secure Your Glass Bottles with a Tamper Evident Seal's Application

- A compact design and gentle handling made for the alcohol and cognac market lines.

- Able to handle a large number of formats

- Quality assurance through the control and positioning accuracy of the sleeve

- A remote feeder magazine keeps up your productivity rate

Features

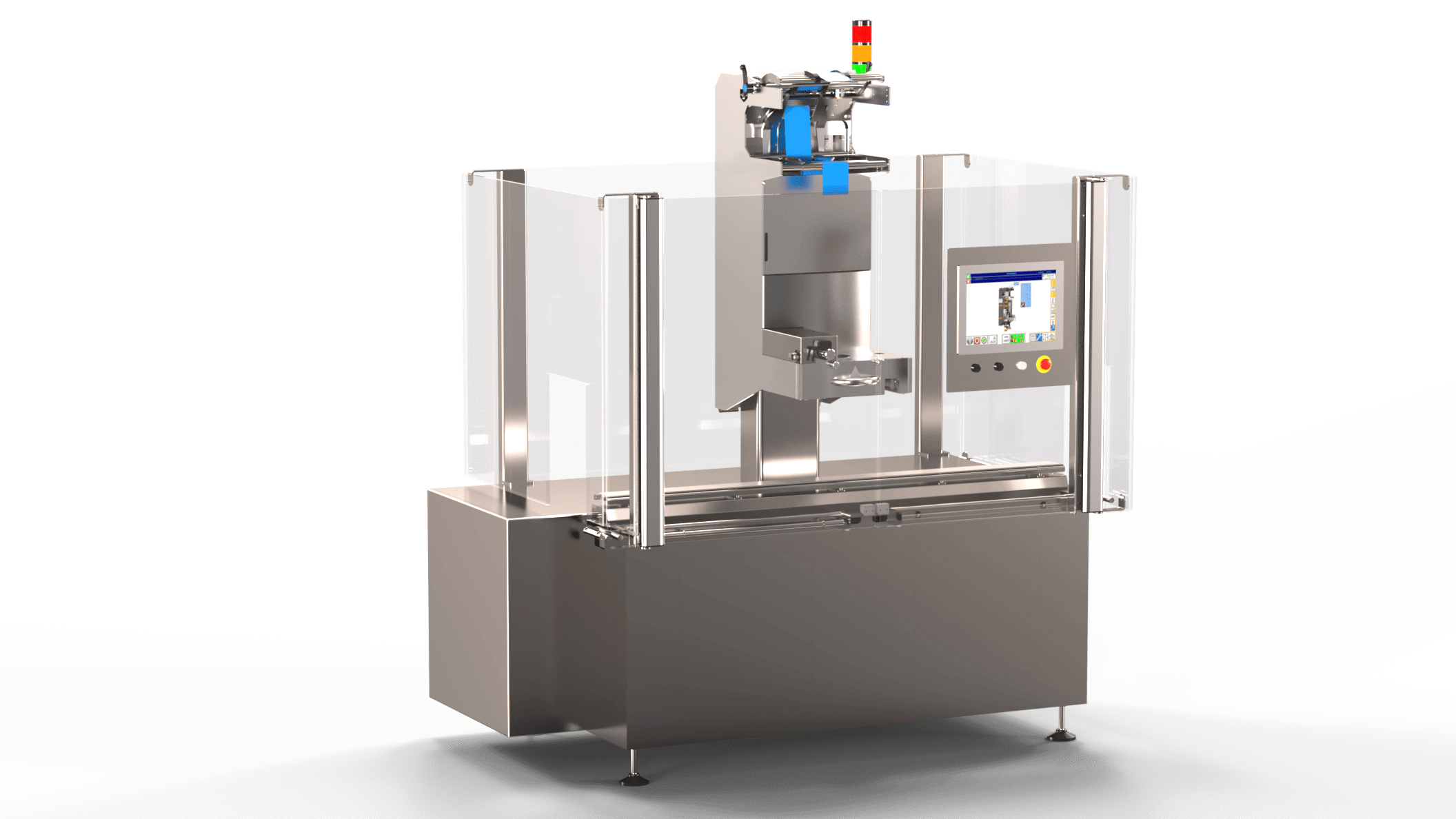

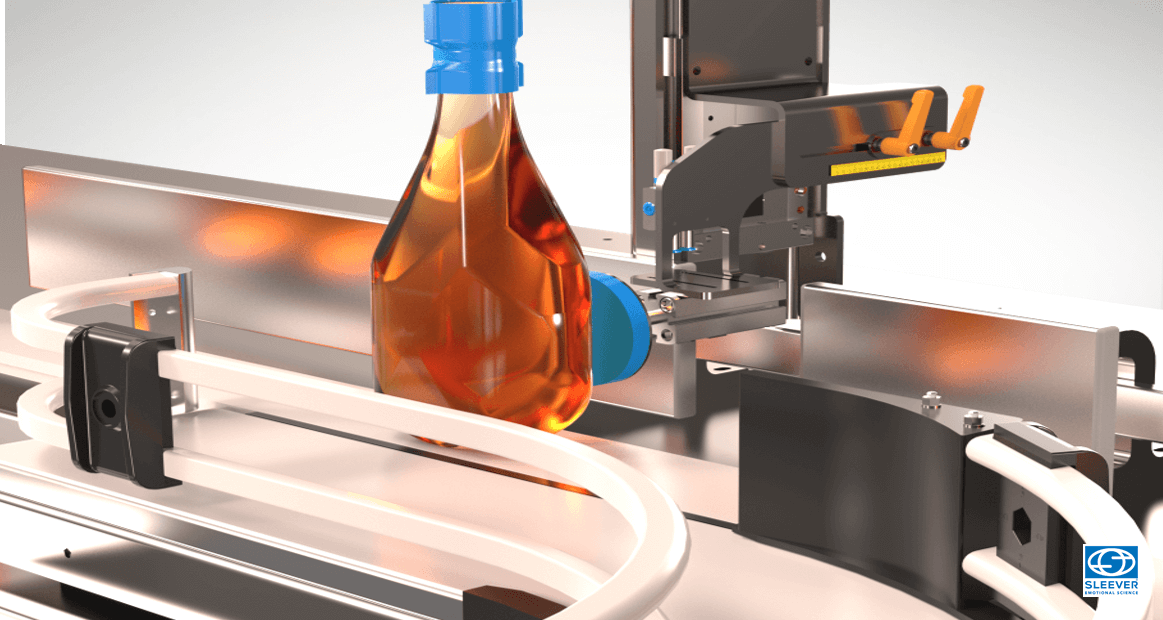

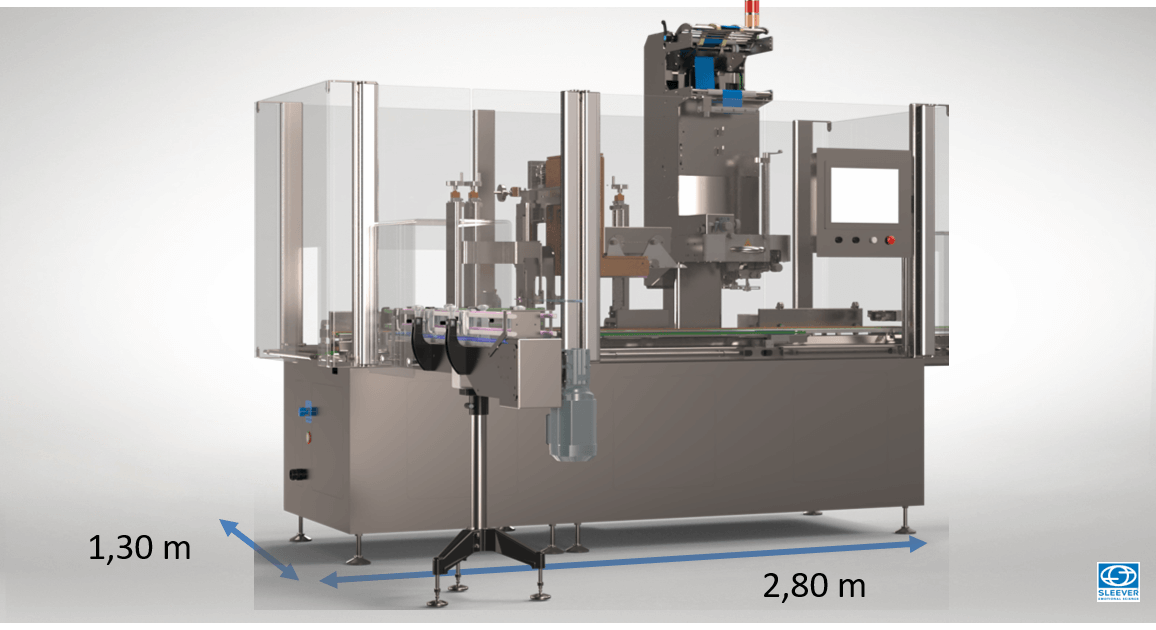

Compactness and gentle handling designed for the alcohol and cognac industry

This compact machine fits into the small workshops that are typically found in châteaux or great wines or cognac companies. Its design ensures the gentle handling and transfer of luxury products: the guides and junctions are adapted to protect the bottles and decanters from any contact with metal, and the control and ejection system is designed to not alter the product.

Freedom of shape and a variety of capacities to secure your decanter collections

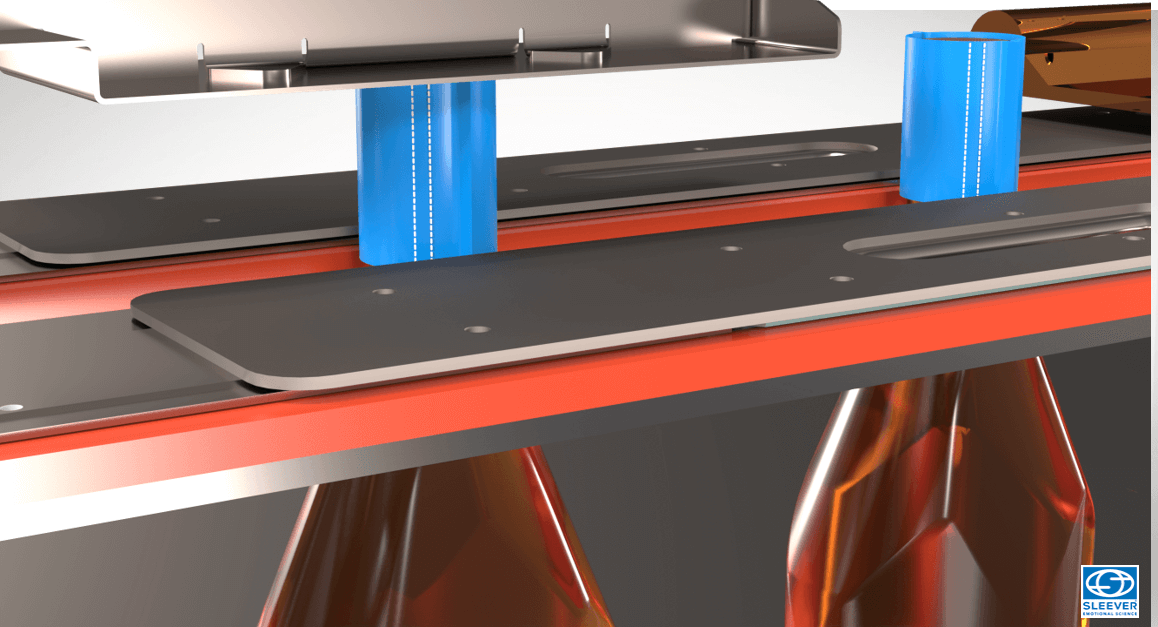

This technology guarantees the successive and alternating use of different sizes of carafes and glass bottles with multiple and varied shapes, capacities and closures. Dedicated tools for each format can be directly replaced without tools.

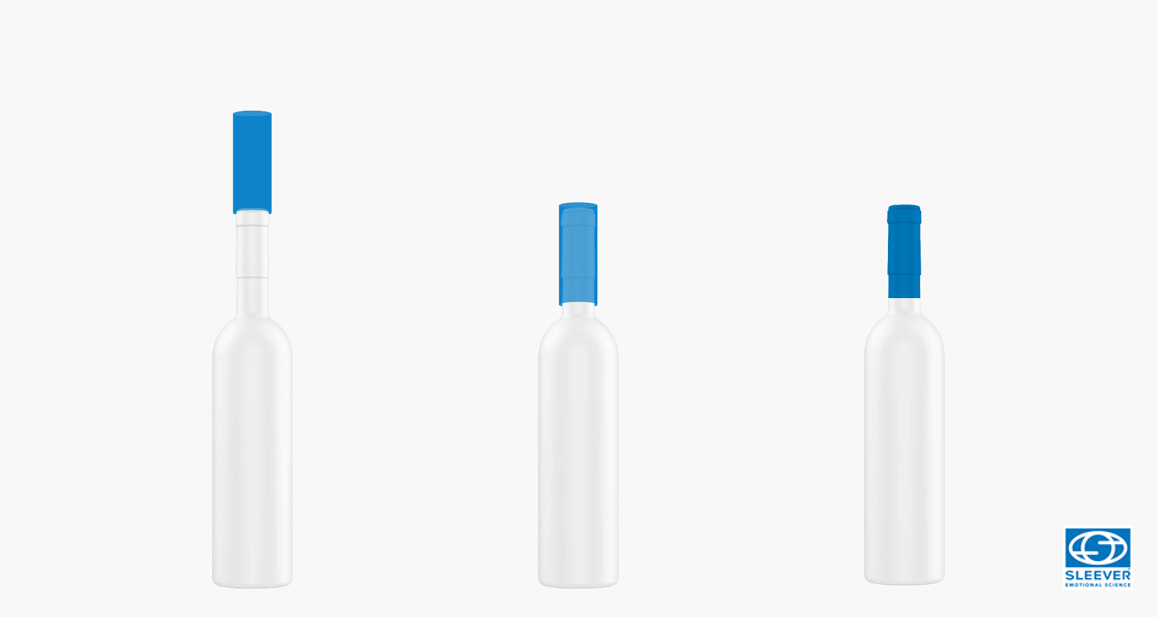

Positioning accuracy that guarantees an outstanding quality finish

For a fast and accurate height adjustment of the tamper-evident seal on your range of caps and corks, a confirmation system combined with a position holder ensures an optimal transfer up to the shrink stage. This system is coupled with a sleeve position control module that validates the required quality level.

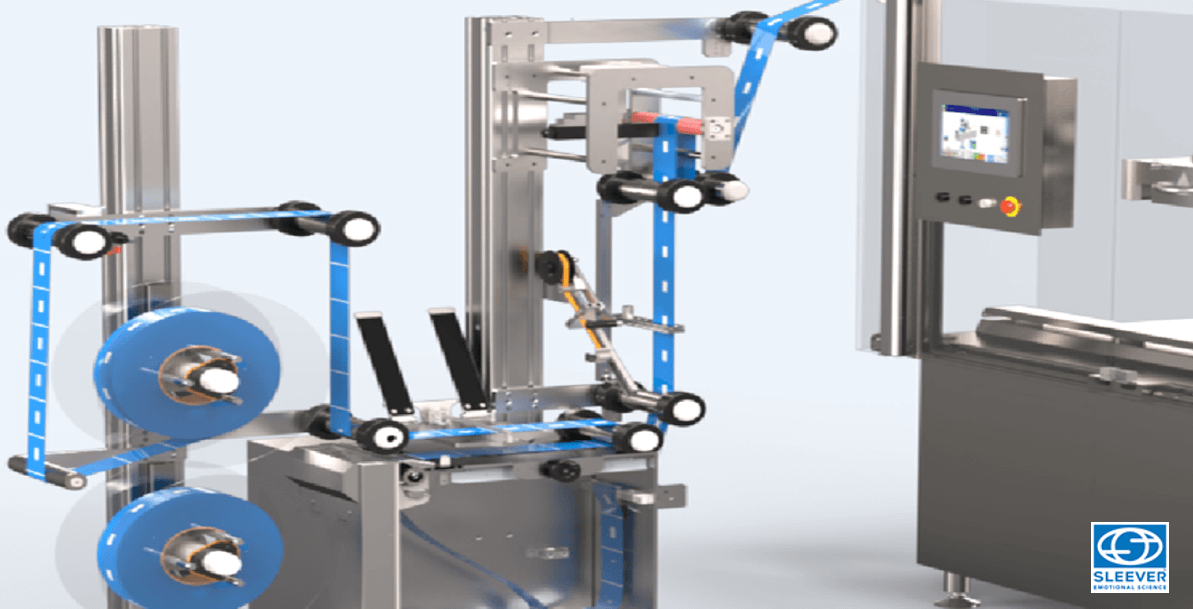

An ergonomically designed unwind unit for continuous production

This remote feeder, which can be oriented according to the line configuration, can be easily integrated into the line while maintaining productivity levels. Sleeve splices are made in masked time to avoid production downtime. The easily accessible reels are positioned at eye level, and splices are made on an ergonomically designed table: the best way to facilitate and secure your operators' tasks.

Options

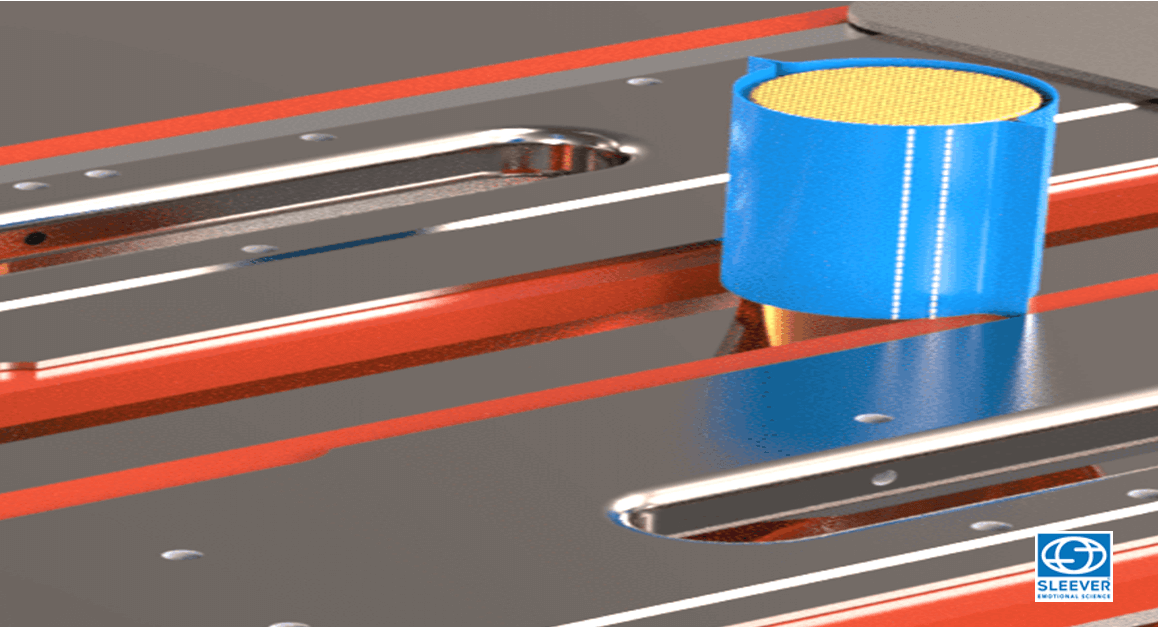

The assurance of a perfectly positioned tamper-evident seal

This module, composed of two belts, allows for the correct height positioning of the sleeve and tamper-evident seal: the first opening guarantee will thus ensure its function of securing the cap or stopper.

Gentle ejection of non-conformities

This module includes all the detection and control cells that allow for the identification of non-conformities that have been previously recorded and parameterized in the PLC. It removes non-conforming products from production with a curved conveyor, equipped with non-metallic guides, to ensure a gentle and careful discharge of the product.

An interactive equipment for a global supervision of your line

This module allows for communication with the upstream and downstream machines in order to regulate the entire line and adjust to its specifications. You can adjust the speed of the conveyor, the start-stop mode, identify the format number with the batch number and/or retrieve data from the production counters.

Optimize your format changeover times

This cart is ergonomic, light and easy to move, specially designed to store your tools and keep them available for the operators next to the machine, and reduce downtime during format changes. The guarantee of having a protected set of tools for a longer life.

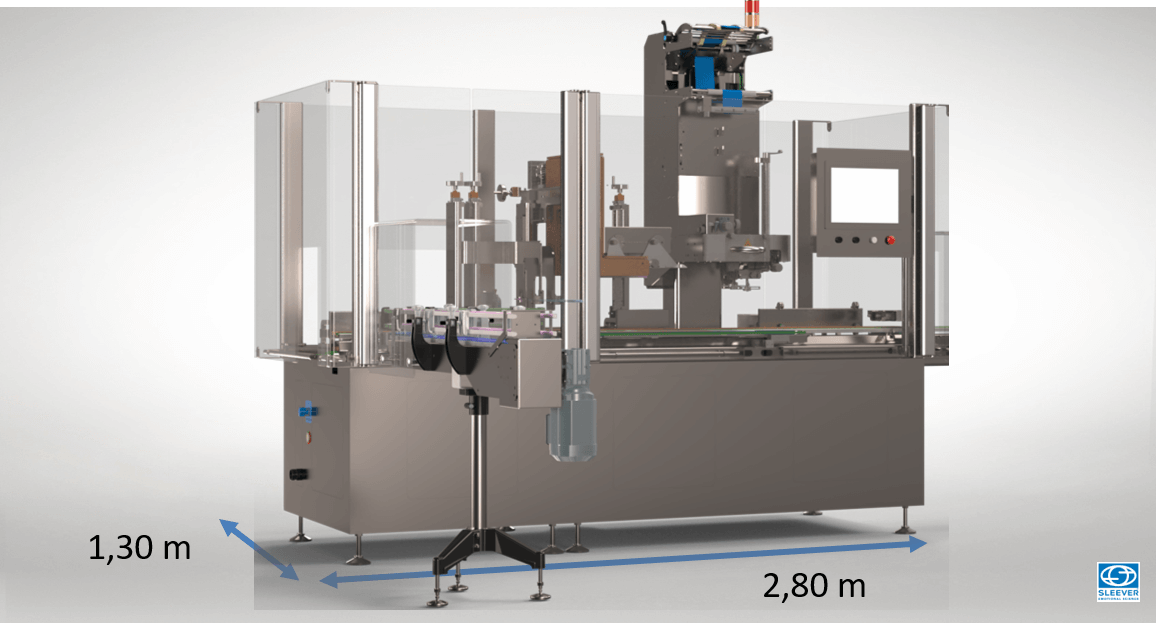

Specifications

Machine

| Conveyor height | 980 mm +/- 50mm |

| Speed | 90 bpm |

| Cutting diameter | 100 mm |

| Electrical consumption | 7 KW/h |

| Machine length | 1800 mm |

Packaging

| Material | Glass |

| Shapes | Cylindrical, square, special... |

| Sizes | 20 ml to 1,5L |

| Products diameter | 20 - 135 mm |

| Products height | 90 - 300 mm |

Sleeves

| Application | Tamper evidence |

| Type of films | PET, RPET & OPS |

| Films thickness | 50 - 75 microns |