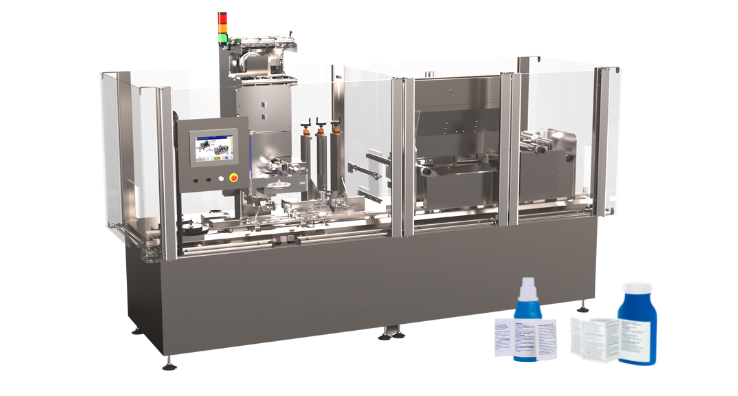

A proven and innovative machine offer to reduce the carbon footprint of your products

- Dedicated equipment for the application of a shrink-sleeve label with a multi-page leaflet to optimize resources

- Modular design for the implementation of a multifunctional shrink-sleeve label

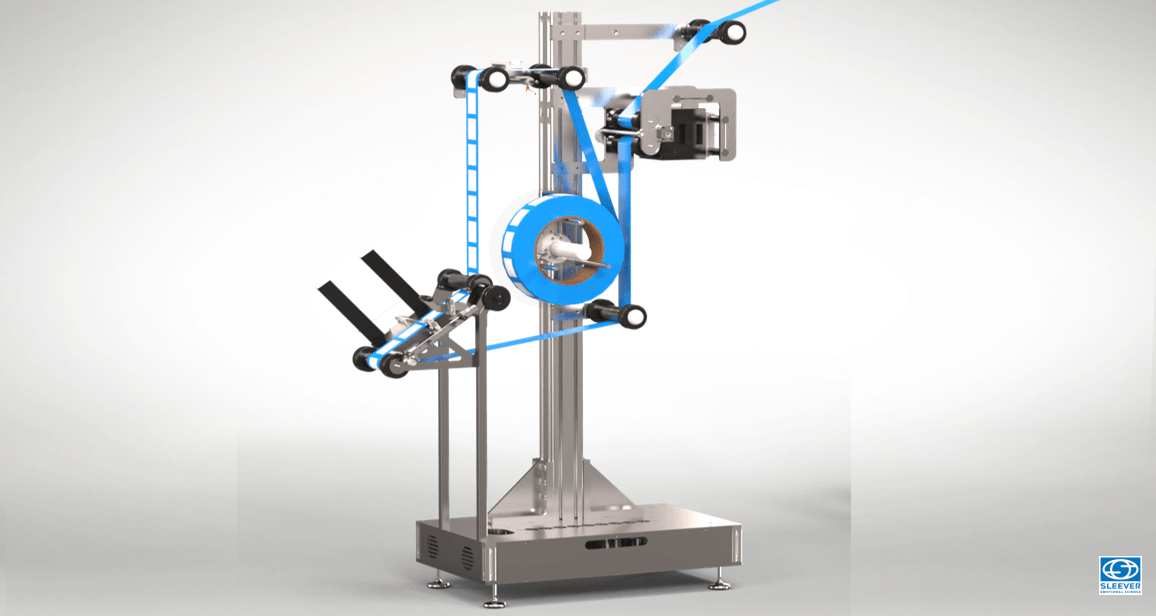

- Unwinding unit adapted to the management of multiple consumables

- An eco-designed equipment, with a controlled energy consumption, to reach carbon neutrality

Features

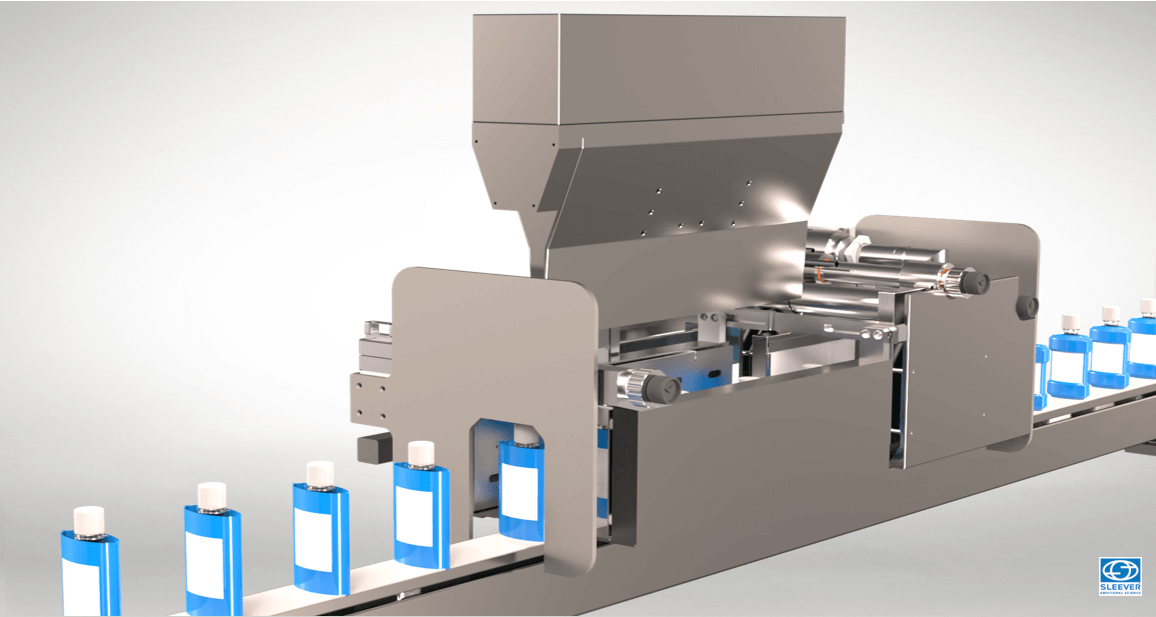

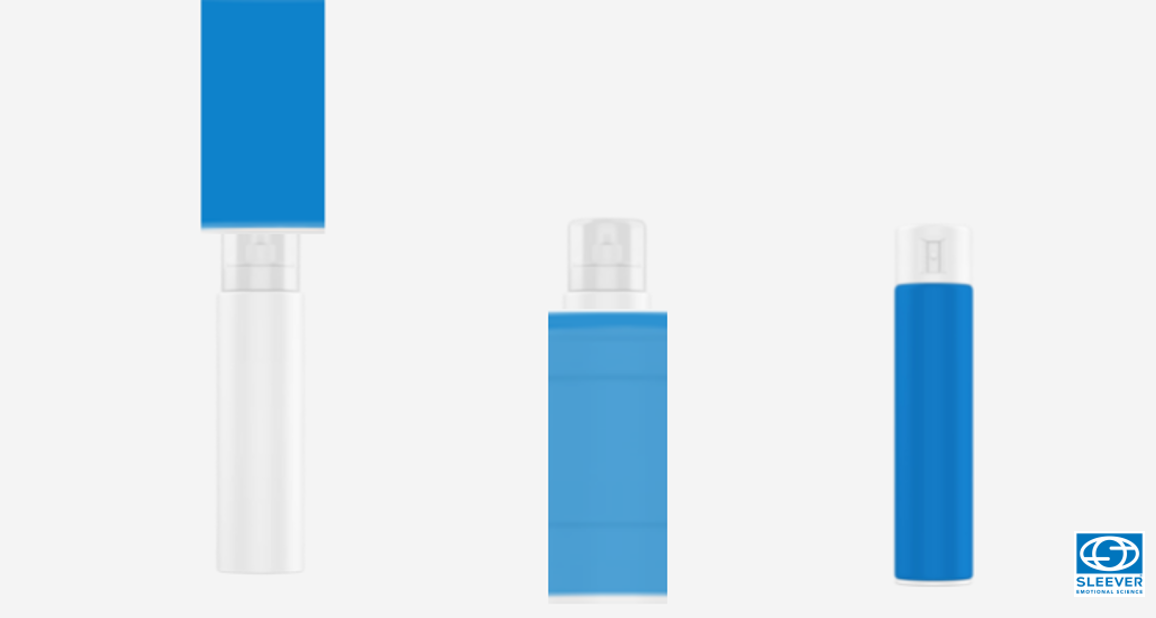

An all-in-one shrink-sleeve label for an optimized packaging

A dedicated, compact and modular equipment that meets industry standards and requirements, to implement Notiplus®: an adhesive-free, full body shrink-sleeve label, that integrates a multi-page leaflet, for an optimized all-in-one packaging.

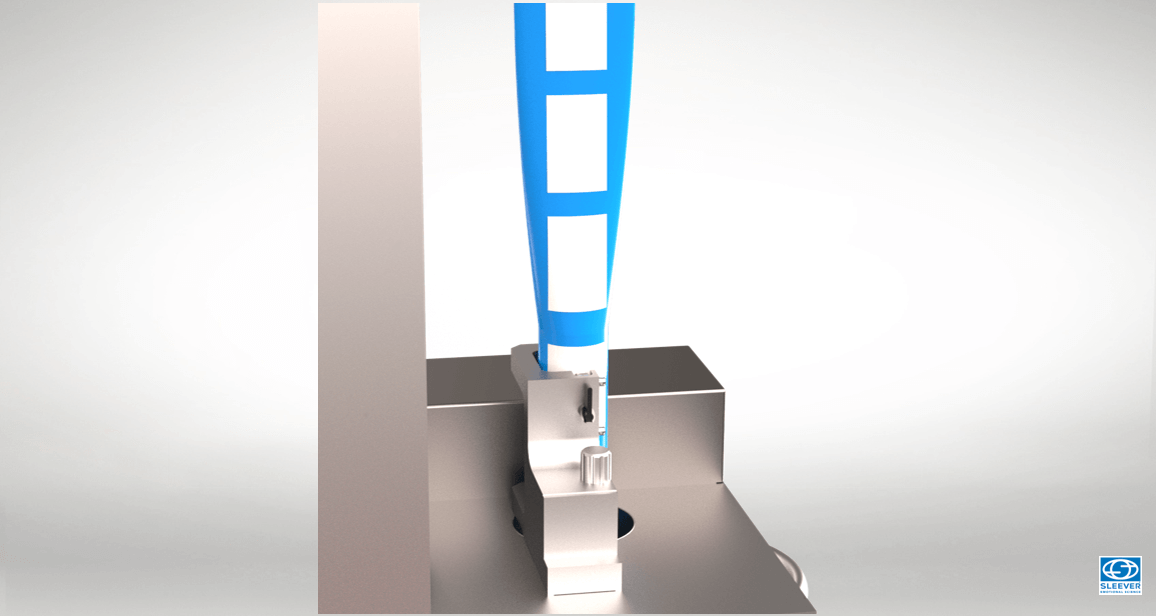

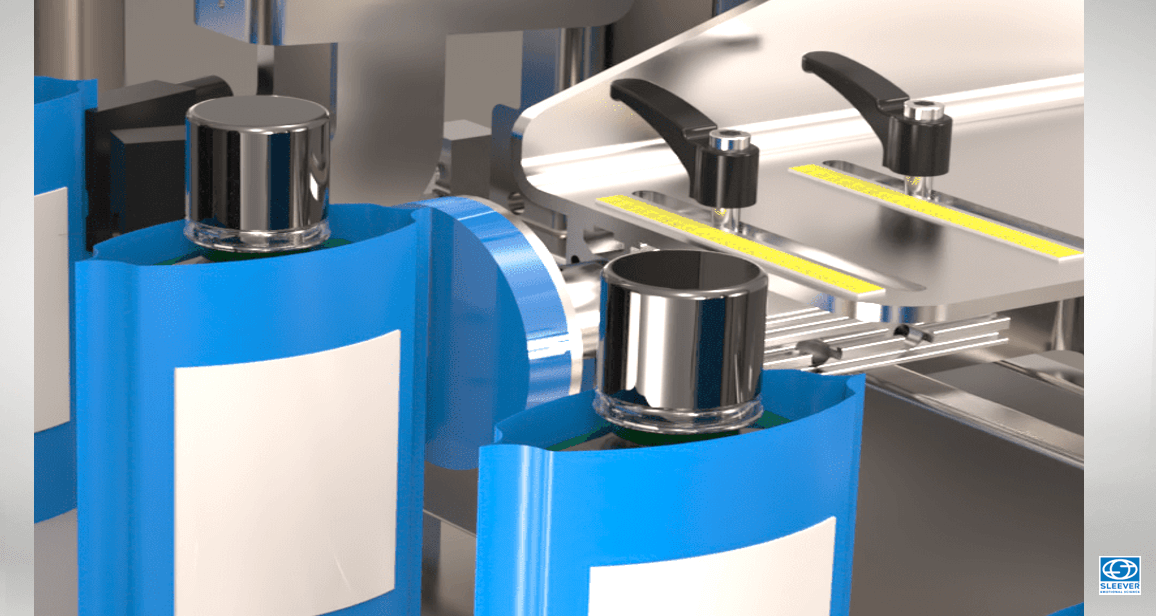

Dedicated module for an all-in-one shrink-sleeve label

This tooling is designed to meet the specifications of this shrink-sleeve product, which includes a label and a multi-page leaflet. It allows to follow the shrink-sleeve during all the stages of the application, while being adapted to the thickness of the notice.

An operator-friendly shrink-sleeve unwinder unit

An unwinder unit designed to support larger mandrels, linked to reels incorporating the overhang of the leaflet. Located outside the machine, it offers easy access to the reels, positioned at man height, and the splicing table allows a fast and error-free operation. The whole system offers autonomy and is operator-friendly.

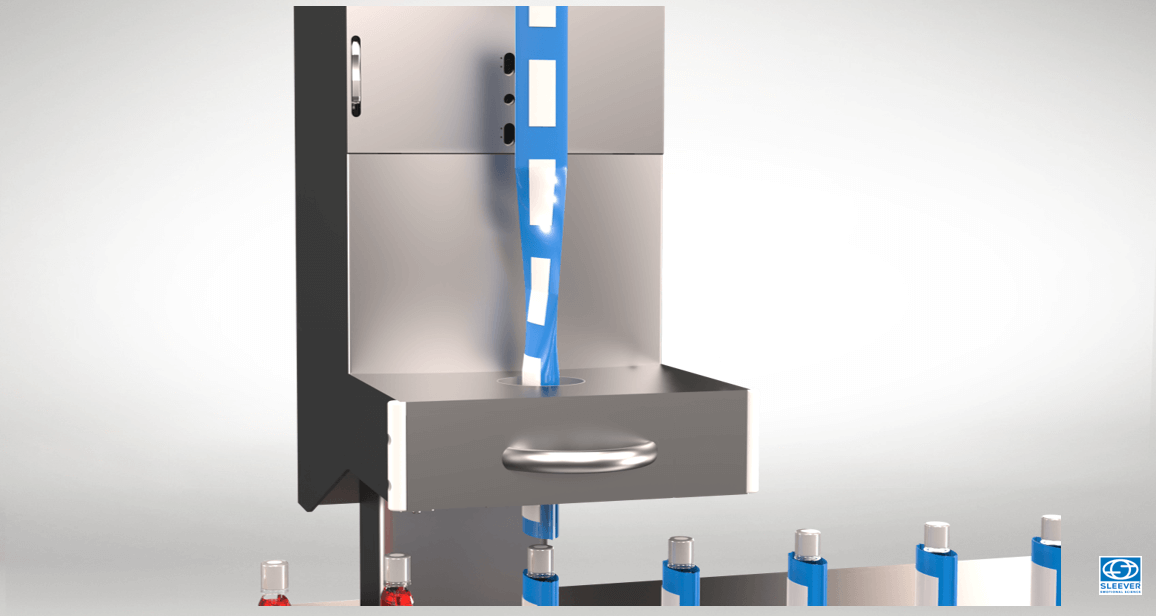

Energy management to reduce the carbon footprint of your products

This exclusive shrink technology combines several systems: the infrared technology adjustement, the height-adjustable tunnel and an exclusive diffusion system are adjusted to each product to optimize energy consumption.

Options

The assurance of a well- positioned leaflet

The shrink-sleeve orientation module allows to adapt to the shape of the container to get the right positioning of the leaflet on the back side of the product. The entire surface of the facing is thus available for product communication.

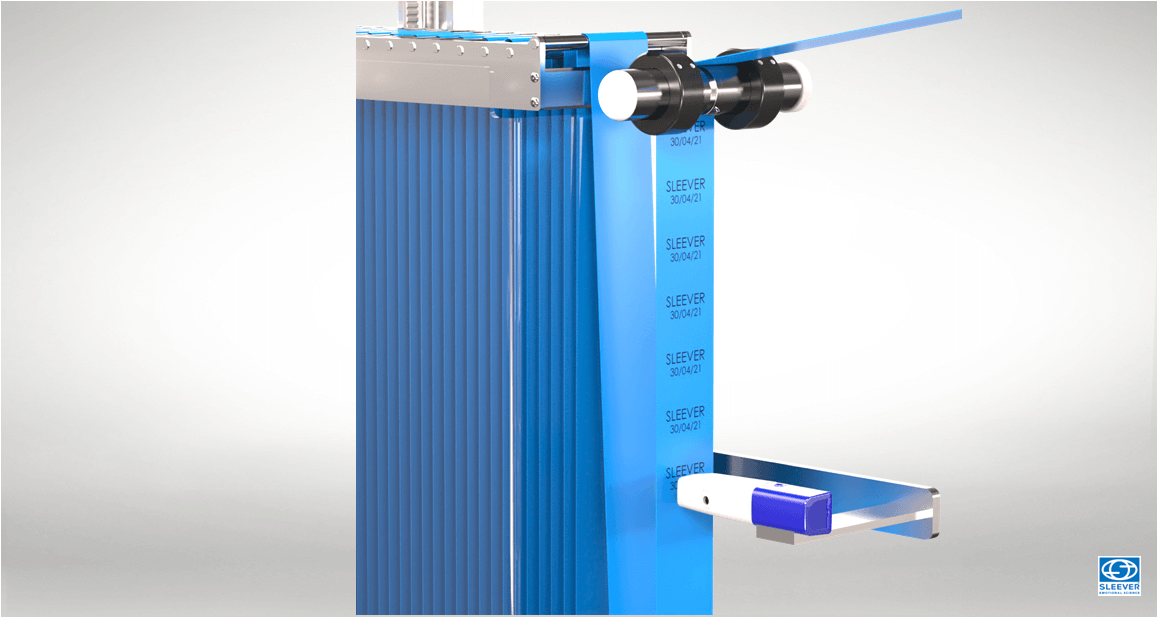

When traceability and unit marking are required

This marking unit allows for various types of marking or coding to meet the needs for traceability and serialization: printing of the expiration date, barcode, batch number, and various information concerning the product. Several printing technologies are available (inkjet, thermal transfer, laser) and can be adapted to your line speeds. It is positioned in the shrink-sleeve unwinder module for quick and easy access.

The performance of your line combined with an efficient control module

This quality control system detects non-conforming products which are rejected via an adequate system (ejection cylinder associated with a bin, or an ejection table with exit conveyor), according to specifications. This ensures performance and guarantees the expected level of quality.

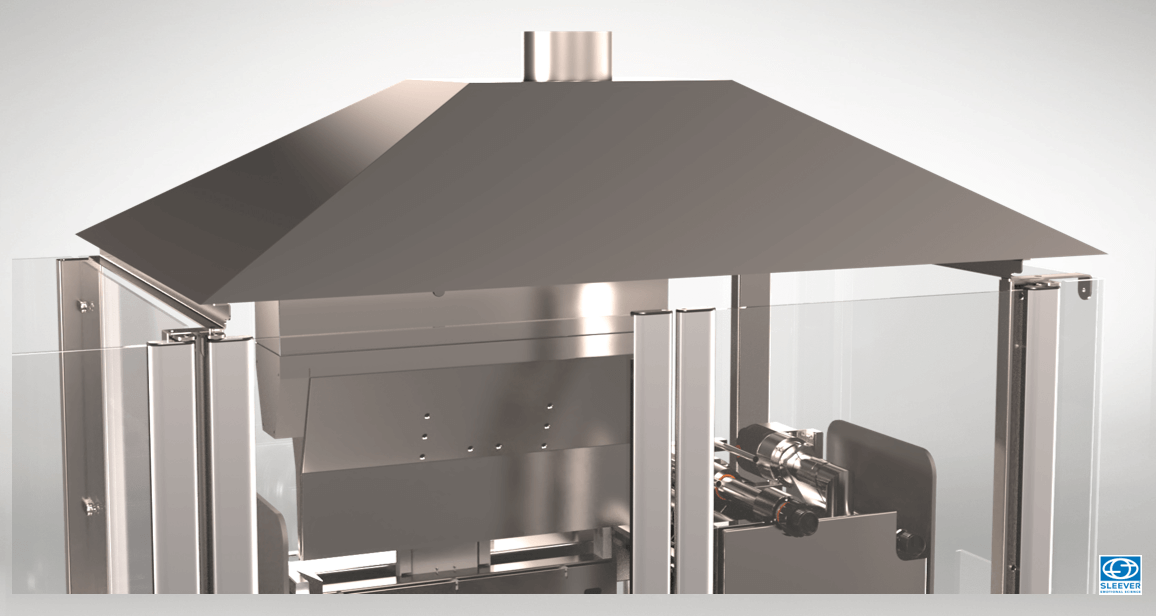

Controlled temperature for working in a controlled atmosphere

The extraction hood prevents heat diffusion related to the shrinking technology and the modification of the temperature in the packaging area. Thus, the working constraints of working in controlled atmosphere are respected.

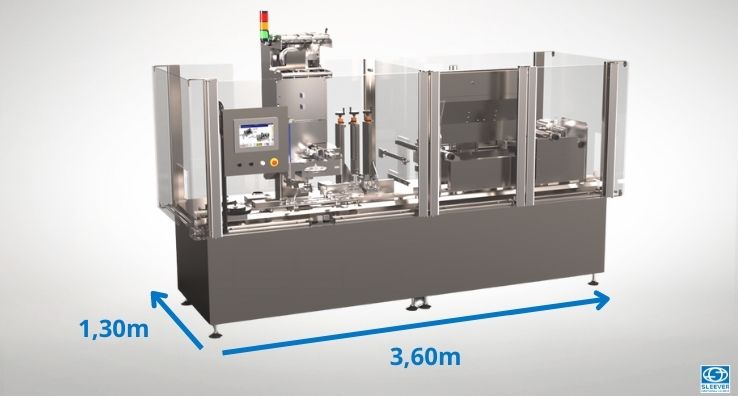

Specifications

Machines

| Conveyor height | 980 +/- 50 mm |

| Speed | 200 cpm |

| Cutting diameter | 100 - 130 mm |

| Electrical consumption | 80 KW/h |

| Machine length | 3600 mm |

Packaging

| Materials | Glass, Plastics, Metal |

| Shapes | Cylindrical, Square & complex Shapes |

| Product diamter | 50 -100 mm |

| Product height | 50 - 200 mm |

Sleeves

| Applications | Full body with leaflet |

| Films | PET, RPET, OPS |

| Film thickness | 40 - 50 microns |