Eco-design and recyclability of your PE-PP packaging

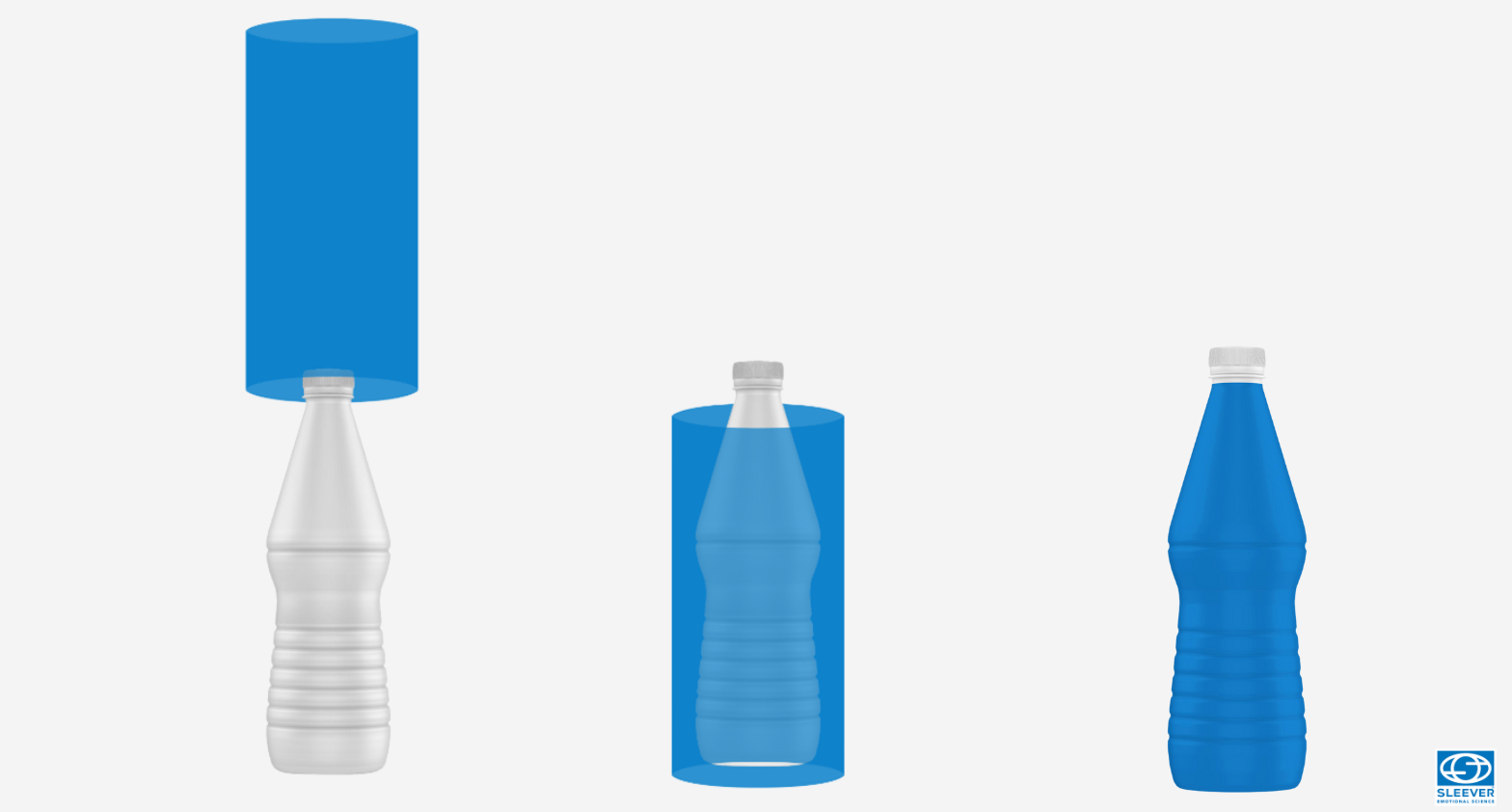

- Bottles decorated with a full-body sleeve label compatible with the recycling stream of PE and PP.

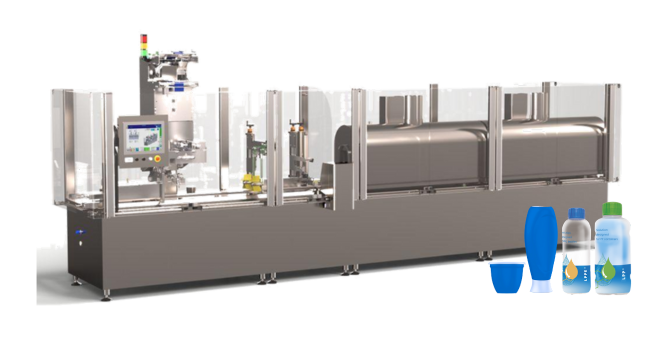

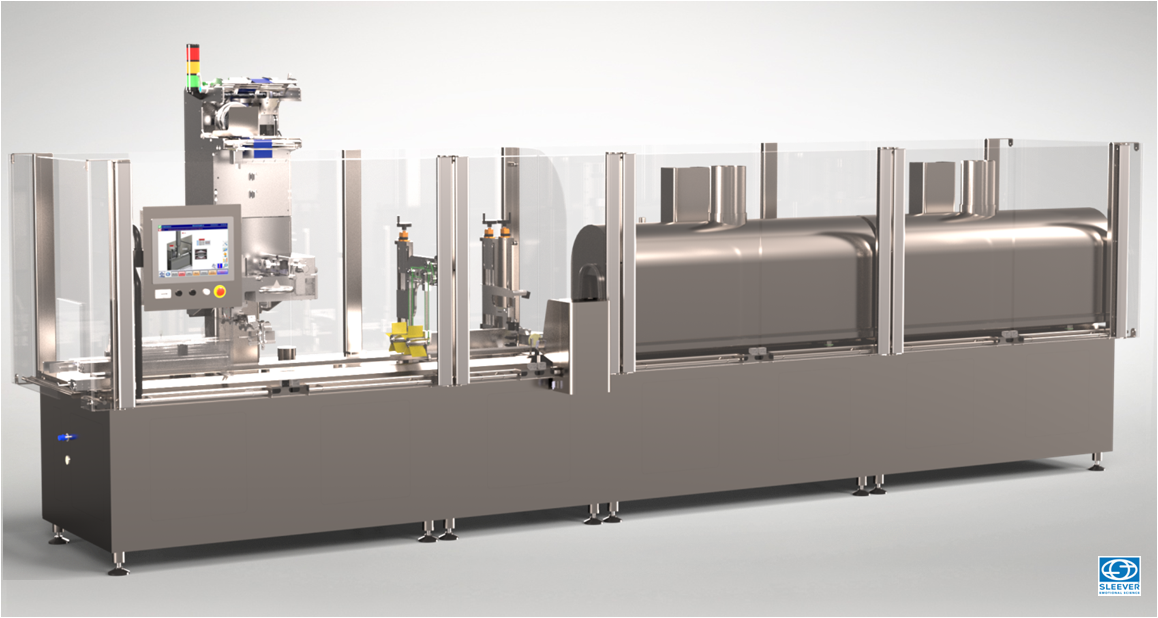

- Modular equipment designed for speeds of 300 to 350 cpm.

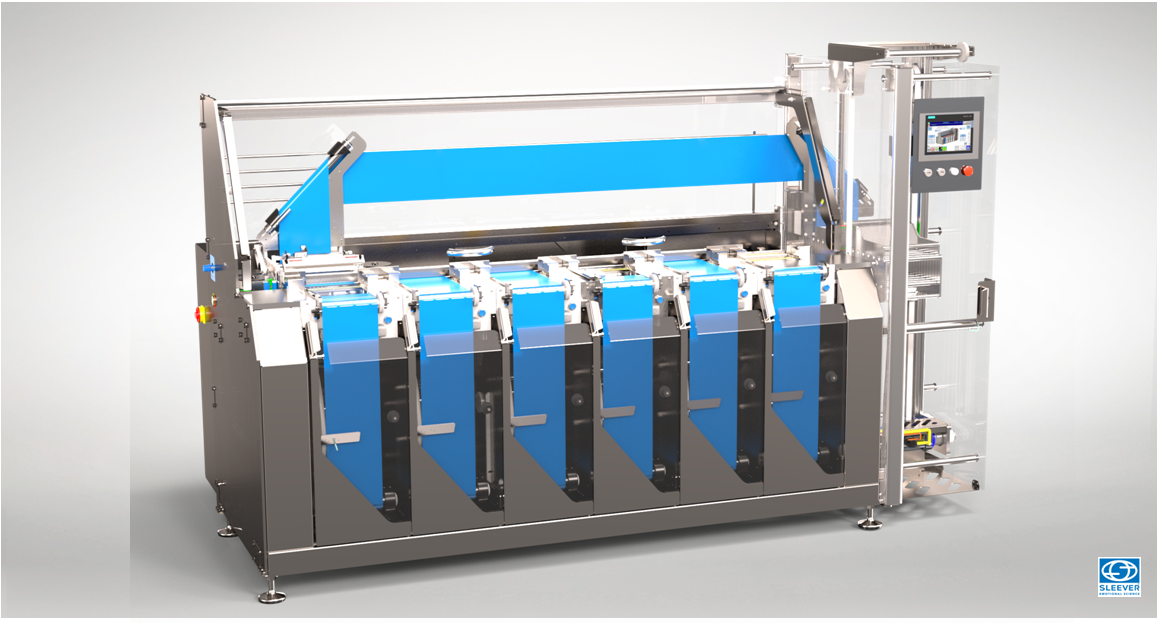

- Ergonomically designed magazine for operator autonomy and comfort.

- Optimized energy consumption to move towards carbon neutrality.

Features

Innovative technology to enhance the recyclability of your PE-PP packaging

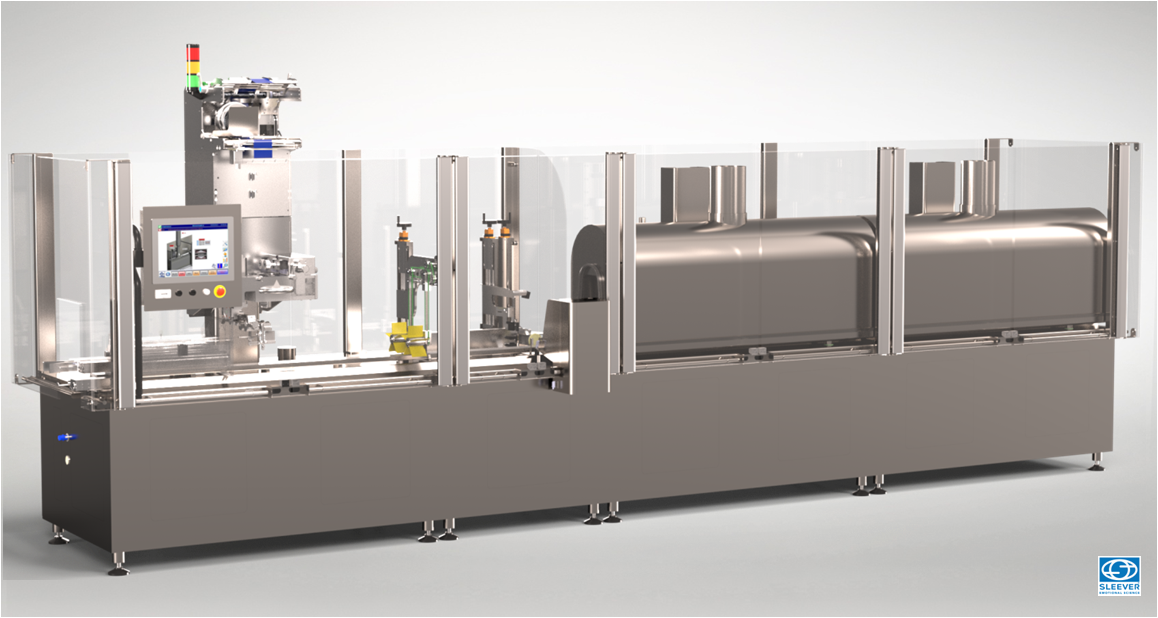

A machine designed to decorate your jars and bottles, ranging from simple to sophisticated shapes, in the liquid food markets. It accommodates sizes from 50ml to 600ml for savory or sweet sauces, condiments, soups, and drinkable yogurts. This equipment enables the application of LPPE® sleeves compatible with the PE and PP recycling steps.

Modules designed for high speeds in the liquid food industry.

This machine is equipped with modules to ensure the performance and quality of the output products: orientation device for complex shapes, control and ejection system to ensure zero defects, and a drying module at the exit of the shrink tunnel to facilitate tertiary packaging under optimal conditions.

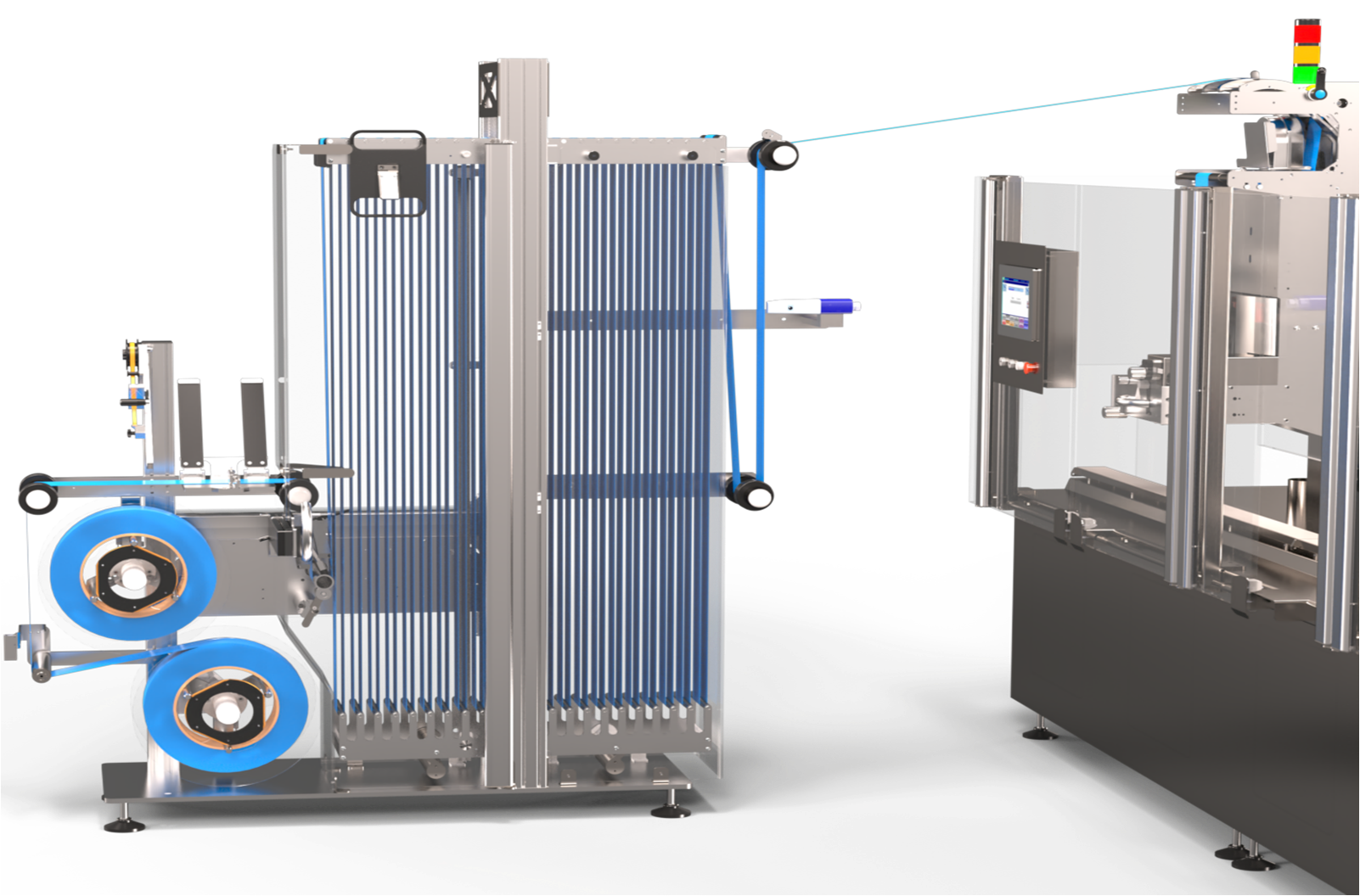

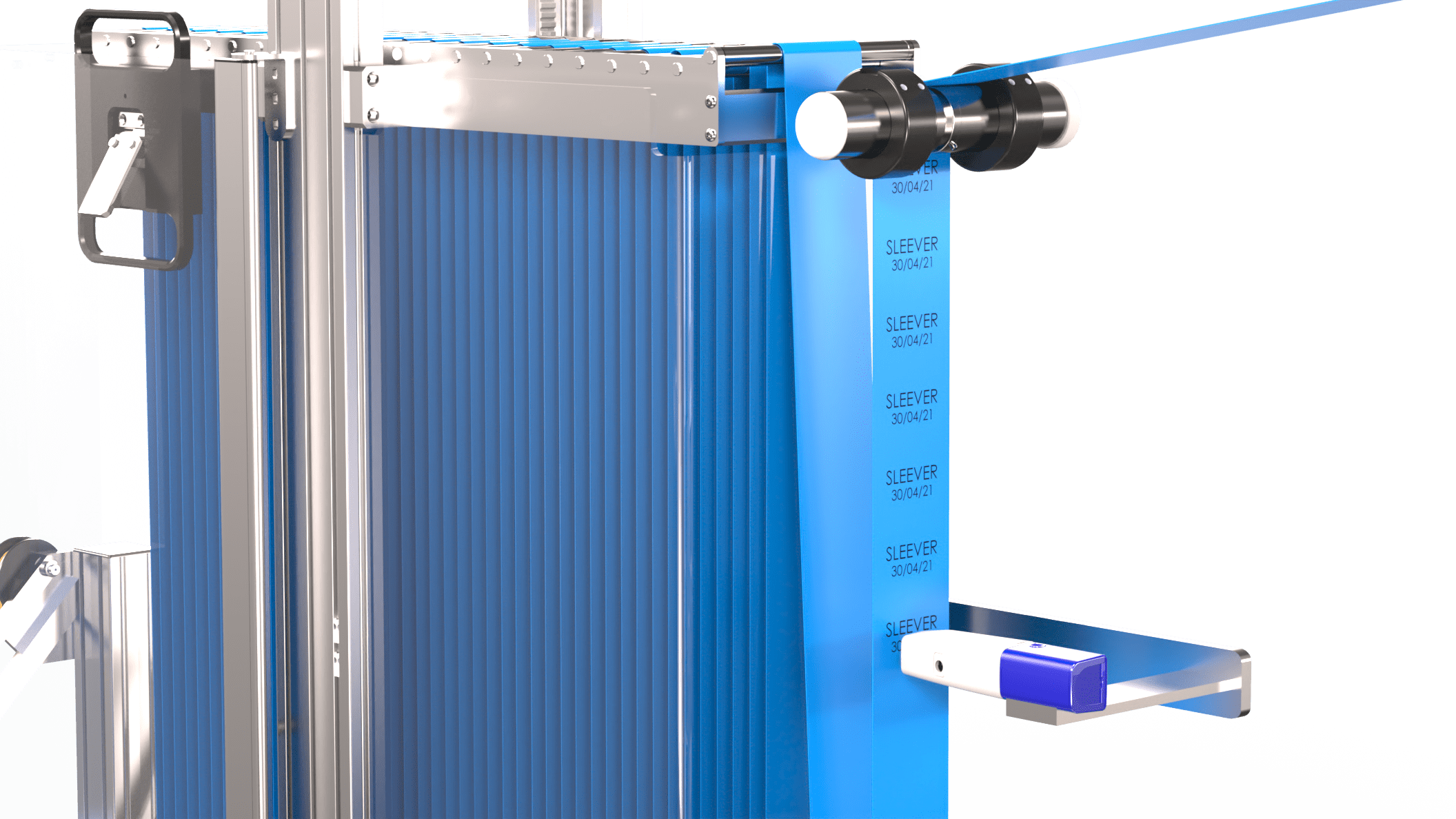

A high-capacity magazine to ensure autonomy.

With a large capacity, this magazine meets high sleeve scrolling speeds, and its design is tailored for next-generation films. Located outside the machine, it provides easy access to the reels, positioned at a human height. Its connecting table enables quick and error-free connections. Altogether, it ensures autonomy and ergonomics for operator comfort.

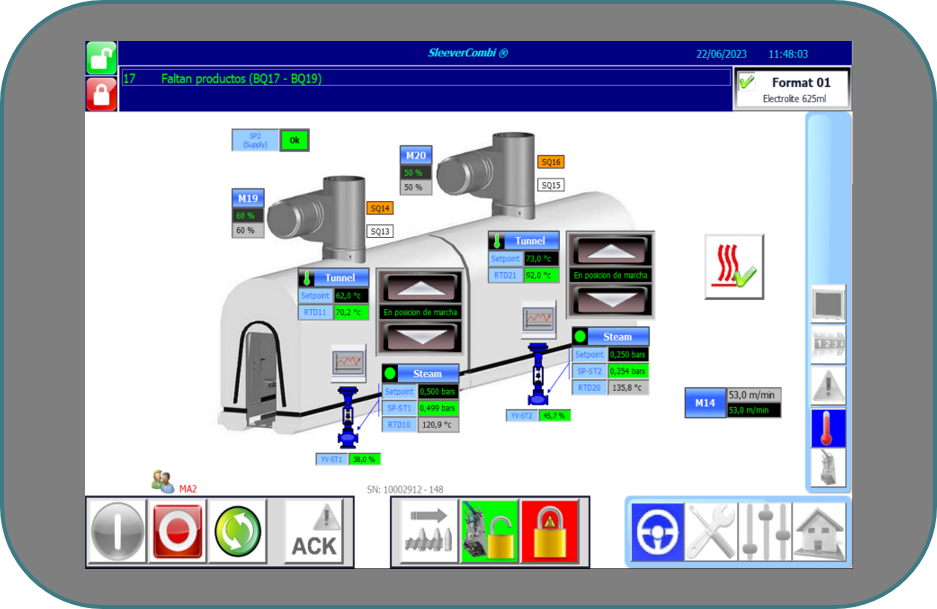

Energy management to reduce the carbon footprint of your products.

This exclusive shrink technology combines several features: the expansion chamber, the lift-lower system, and the steam diffusion array adjust to each format, with centralized parameter management from the 12-inch HMI. This system optimizes energy consumption.

Options

Operator comfort remains the priority for high-speed production lines

This equipment comes with a multi-reel device and an integrated automatic connection function, ensuring zero machine downtime. It is specially designed for operators managing a production line, enabling them to increase their autonomy and productivity gains.

When traceability and unit marking are required in food markets

The marking is positioned within the high-capacity magazine module for easy and quick access. It allows various forms of marking or coding to meet traceability and serialization needs: printing of expiration dates, barcodes, lot numbers, and various product information. Multiple printing technologies are available: inkjet, laser, etc., adapting to the line speeds of food markets.

Master your format changeover times with the carrying trolley.

An ergonomic tool-carrying trolley, lightweight and easy to move, available for operators, specially designed to store your tools and keep them accessible next to the equipment to reduce downtime during format changes. They are protected when not in use and during transportation.

Specifications

Machines

| Conveyor height | 980 mm +/- 50mm |

| Speed | 300 cpm |

| Cutting diameter | 100 mm |

| Steam consumption | 300 Kg/h |

| Steam pressure | 6 - 8 bars |

| Electrical consumption | 12 kW/h |

| Machine length | 6400 mm |

Packaging

| Materials | HDPE- PE |

| Shapes | Cylindrical, square, complex shapes... |

| Products diameter | 45-90 mm |

| Products height | 185 - 210 mm |

| Sizes | 20 cl - 1 l 80 gr - 800 gr |

Sleeves

| Applications | Full body, partial sleeve |

| Type of films | LPPE |

| Films thickness | 50 microns |