Enter the circular economy with a machine dedicated to your dry PET packaging

- Your product labelled with a full body shrink-sleeve label to enter the post recycling stream (dry food, beauty, pharmceutcial)

- A modular machine designed for high production rates

- An ergonomically designed shrink-sleeve unwind unit for the operator's autonomy and comfort

- Optimized energy consumption for carbon neutrality

Features

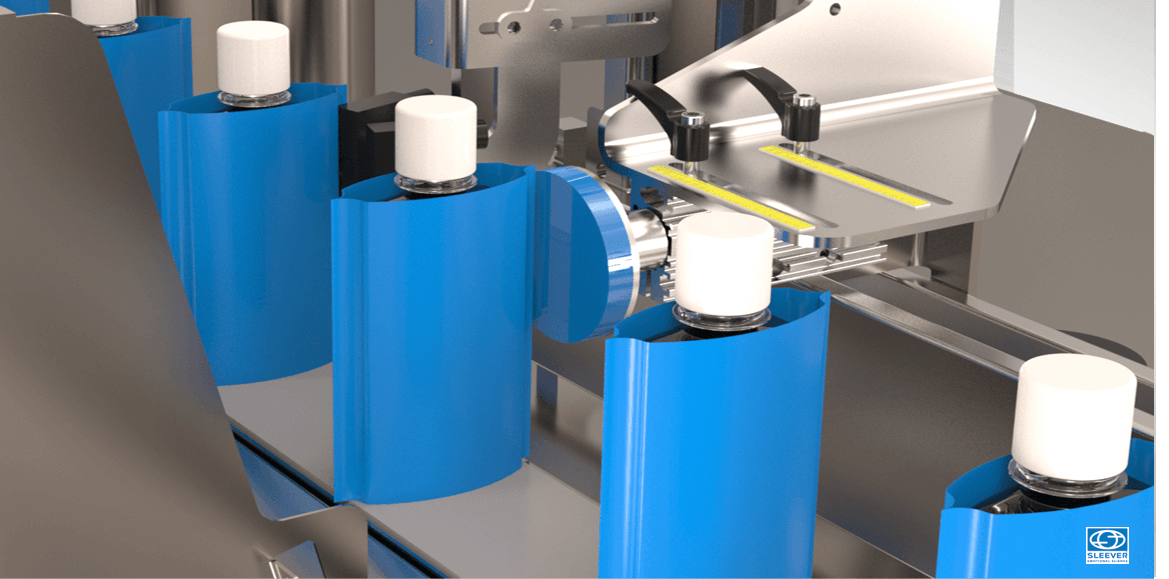

Modules designed for the speeds required by food, healthcare, and cosmetics markets

This machine is availale with modules to guarantee the performance of your process and quality of your products: an orientation module for complex shapes, and control and ejection module.

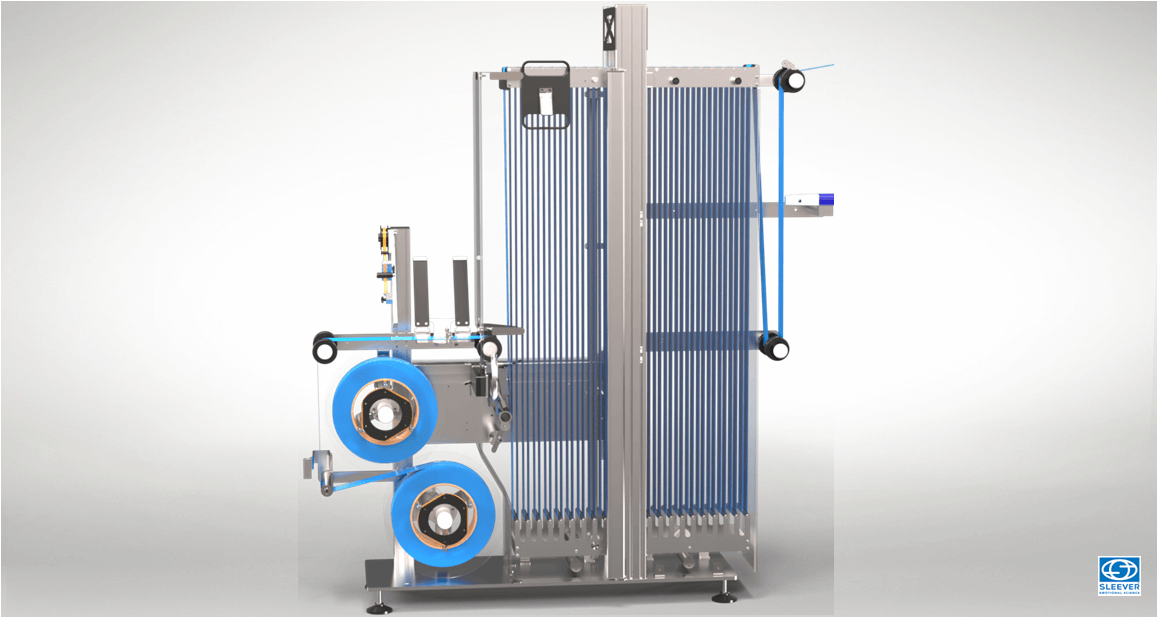

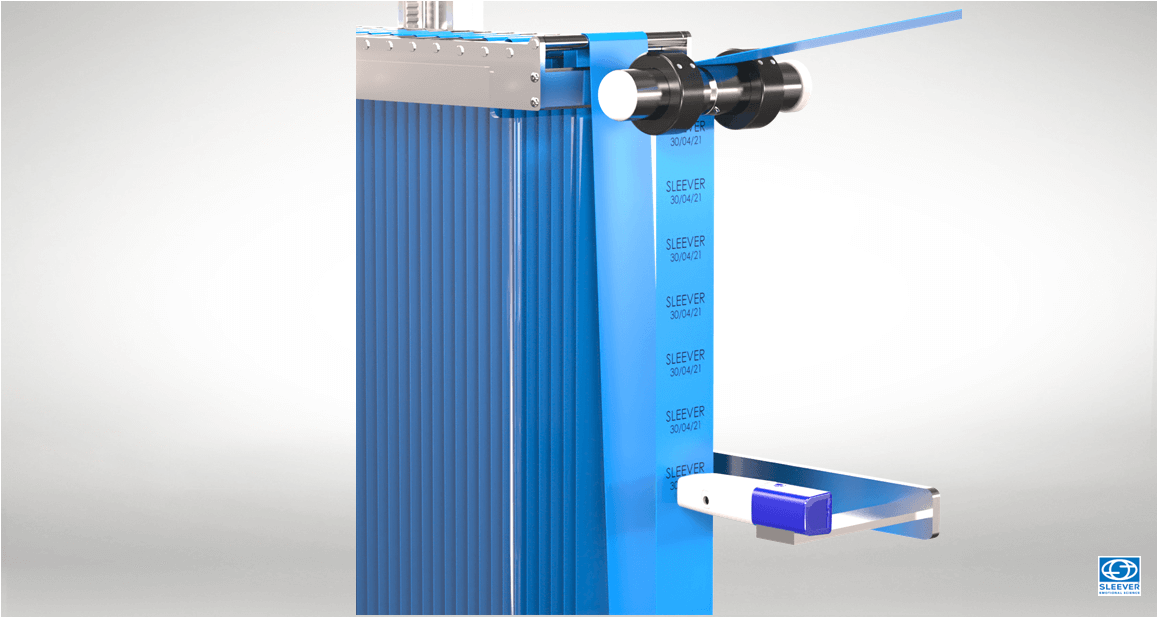

An ergonomic design for quick and easy reel sfeeding, a large capacity sleeve unwind unit for autonomous use

This high-capacity magazine handle your line requirements and is designed to accommodate eco designed shrink-sleeve. Built as a separate module, Iit offers easy access to the reels;the splicing table allows quick and error-free splicing. The overall system provides autonomy and ergonomics for operator comfort.

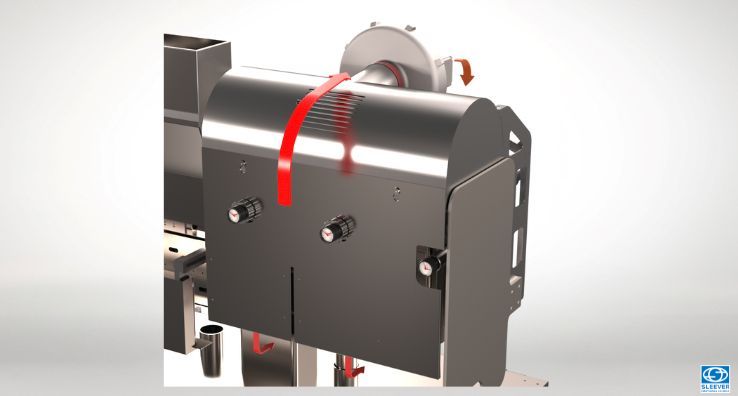

Energy management to reduce the carbon footprint of your products

This shrink-sleeve label technology combines several advantages: the infrared technology, the height-adjustable tunnel and the hot air distribution system are adapted to each product to optimize energy consumption. The hot air reintroduced above the heat exchangers at the end of the shrinking process is recycled. This is a closed loop process. The hot air nozzles only provide the additional heat to reach the set temperature and reduce consumption by 50%.

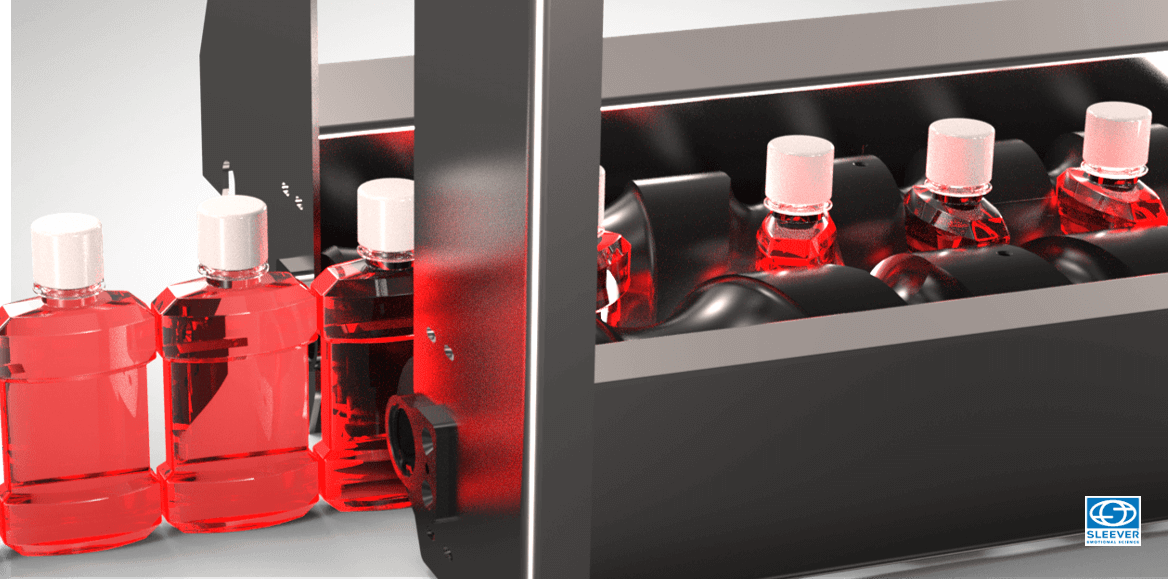

An innovative technology for the recyclability of your dry PET packaging

A machine designed to decorate all full or empty packaging whichare sensitive to humidity for example confectionery, health, and cosmetics products. Flexibility of capacity (100gr to 2kg), and shapes (classic and sophisticated). This machine allows the use of the LDPET DS ® product, a heat-shrinkable shrink-sleeve label dedicated to the recycling of dry PET packaging in closed loop.

Options

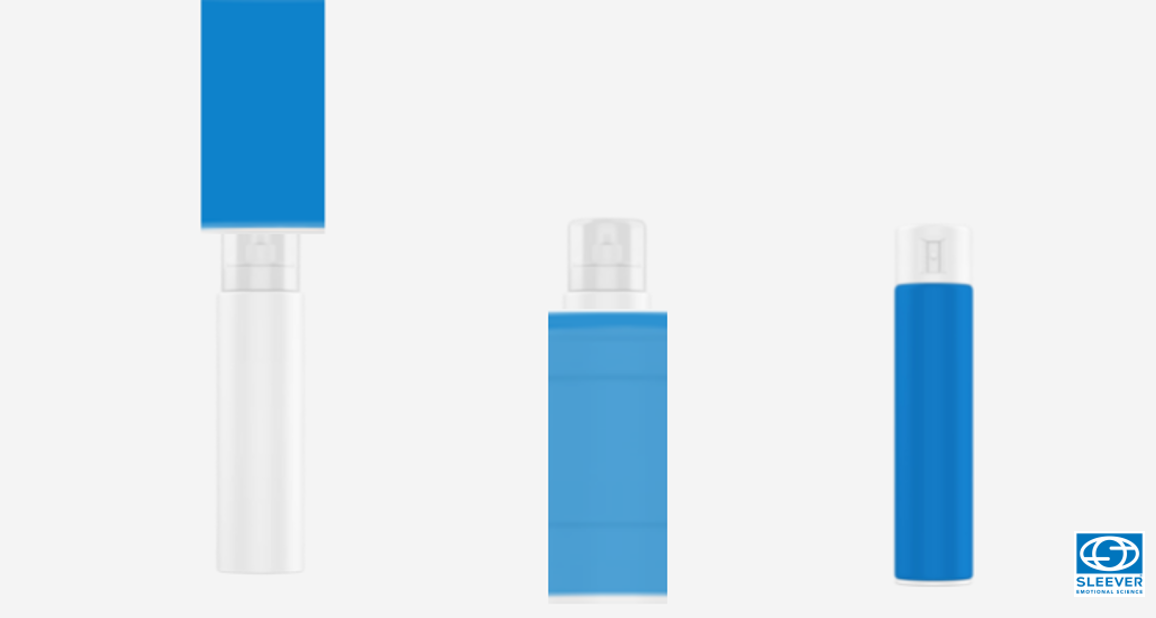

The assurance of a well-oriented product

The orientation module in the screws ensures the correct positioning of the PET packaging before the shrink-sleeve is applied. It allows the machine to adapt to specific packaging shapes, for example square or rectangular profiles.

With modularity become the key of your performance

This compact monobloc machine, stainless steel, can be equipped with different modules to meet your requirements. With multiple configurations of single or double application modules and single or multiple shrink tunnels.

When traceability and unit coding are needed

This unit integrated into the reel feeding module for easy access and control. Different types of marking or coding are available: printing of the use-by date, barcode, lot number, and various product information. The technologies chosen are adapted to the line speeds of your products' markets.

For multiple communication uses

This module allows for communication with upstream and downstream machines to regulate the line and improve efficiency. Being connected allows you to open up to the outside world and allows for remote assistance, which can be used for diagnosis and remote intervention if necessary. A solution that optimizes travel costs for certain interventions and saves time.

Specifications

Machines

| Conveyor height | 980 +/- 50 mm |

| Speed | 120 -250 cpm |

| Cutting diameter | 100 - 130 mm |

| Electrical consumption | 15 to 40 KW/h |

| Machine length | 3600 mm |

Packaging

| Shapes | Cylindrical, complex shapes... |

| Product diameter | 45 mm - 125 mm |

| Product height | 100 mm - 200 mm |

| Sizes | 20 gr - 2 kg |

| Material | PET |

Sleeves

| Applications | Full body |

| Films | TPEG, PET, LPPE |

| Film thickness | 20 - 75 microns |