Sleever Machines Group

With over 1300 machines installed worldwide and 45 years of expertise, we are a major stakeholder in the shrink sleeve industry. The Sleever Group's mastery of the entire process has allowed us to offer expertise and optimal implementation.

Our manufacturing plants and expert centers on five continents make customer service key to our success: We think global, we act local.

SHRINK-SLEEVE EXPERTISE FOR EQUIPMENT PERFORMANCE

An industry reference

With our unique expertise in this technology, we have put it to work in capital goods, from design to manufacturing to commissioning.

We accompany you throughout the life of your products.

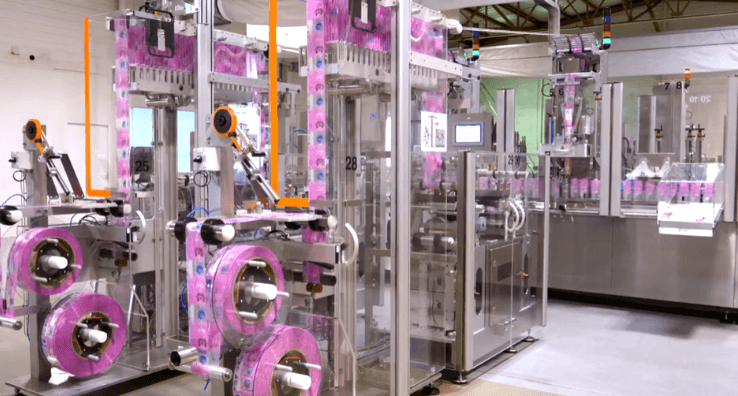

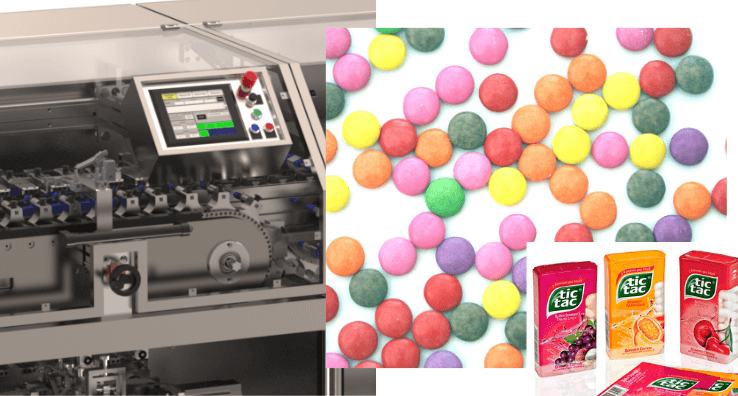

Equipment designed for operators

Our machines offer easy-to-use features that allow your operators to run them and ensure performance with simple, safe and tool-free operations. The graphic and tactile interfaces are enriched with modules such as preventive maintenance or multilingual technical documentation.

The remote access modules allow you to keep a constant link with our hotlines and expert centers around the world.

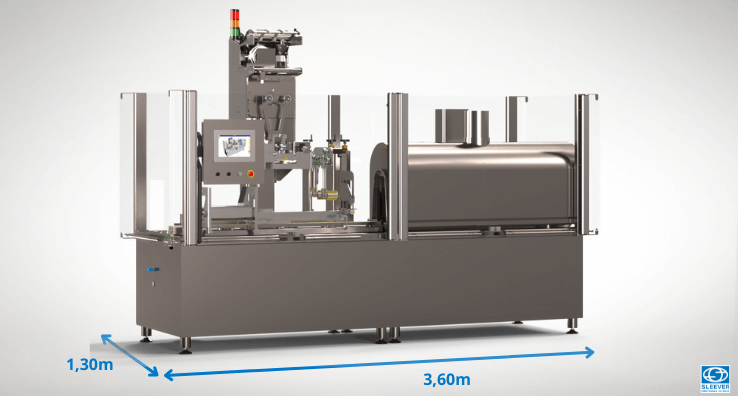

An original, agile and interactive design

A monobloc design with a reduced floor space, integrated electrical cabinets, and a transparent 360° enclosure optimize your workspace.

A wide range of modules offer additional functionality, depending on the product requirements.

Thus, our offer adapts to the configuration of your plants and your needs.

Industrial solutions for all markets

Whatever the configuration of your packaging lines, the challenges of your markets, or the specificities of your project, we have a range of adapted equipment: expert machines, specialty machines, and stand-alone machines will provide the industrial solution you are looking for.

expert machines for markets ranging from food to beauty, specialty machines for specific uses, from pharmaceuticals to make-up, stand-alone machines for specific industrial needs such as FabLab and service providers.

A LOCAL FOOTPRINT, A GLOBAL MINDSET

An international footprint and vision

Sleever Machines Group's 200 employees, who are experts in R&D, technology and equipment, design and develop machines for our clients worldwide. Our production sites in France and Germany are in permanent contact with our expert centers, support services and sales teams.

We are present in the USA, South America, Western Europe and Asia (China, Australia). Thus, you can benefit from our support 24/7.

Local offices to ensure proximity

- Expert centers for your future developments, Fablabs at your disposal to test and qualify your products.

- Support services with engineers and technicians who provide know-how and assistance in your language, close to your plants.

- Project management, studies: a transnational know-how, with modern and powerful management tools, make our project engineers the men for any situation.

- Agile, interactive and multidisciplinary local teams.

OVER 40 YEARS OF INNOVATION AND PASSION

1975: Creation of Sleever Machines Group

As the innovative pilot of the "shrink-sleeve" concept, the Sleever Group continued its development and invested in the construction of capital goods to offer its clients a global and efficient solution. A development path marked by innovation and acclaimed by numerous awards and trophies.

1981: a global and efficient approach for a worldwide breakthrough, the toothpaste dispenser

The combination of the heat-shrinkable sleeve to cover and secure a pump dispenser. Awarded a Packaging Oscar, it is a unique concept, which offers a global, efficient and tailor-made approach to meet the expectations of this new consumer concept.

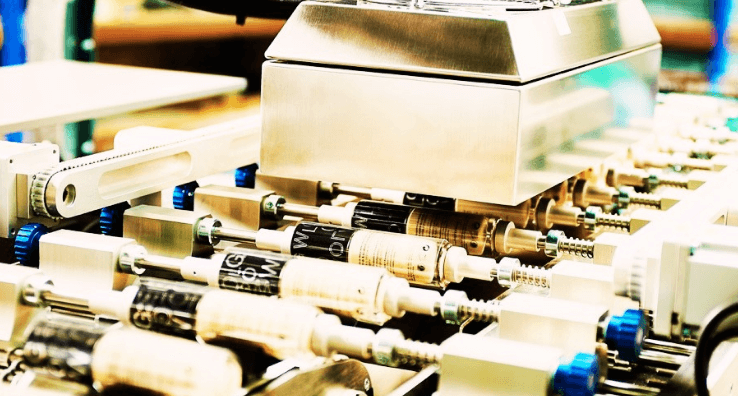

1990: security and tamper proofing of pharmaceutical devices

A strong and lasting commitment: the design and construction of equipment for the pharmaceutical industry market.

Meeting the technical requirements and specifications that are specific to these markets: 25 years of expertise serving the world's largest laboratories.

2002: Providing the ultimate personalization with a unique offering to confectionery brands

Specifically designed to package small, unstable products on lines, this equipment, which can be installed horizontally, allows for the complete packaging of multiple references of these small confectionery packages.

Unstable products, mini-formats, rich visuals, custom shapes, everything to make your product an iconic concept. A global success, as well as high performance, high speed, traceability and serialization.

2007: everything has been said but we took it a step further

Limited edition events to boost sales of this global brand in its various markets, with a series of 360° displays. A challenging product due to its shape, its material, its implementation constraints: we accompanied the brand campaign after campaign, and we were very audacious with it.

2013: Beauty and make-up, the daily need for the senses

Sensory packaging, enhanced with limitless visual effects, or "lace" texture effects offered a new dimension to makeup products. This iconic mascara line was launched worldwide,

Agility, proximity, expertise, this is what the Beauty world expects to constantly invent and respond to changing markets.

2015: the first days in complete safety. Confidence is not something you improvise

Babysafe®, the first-opening guarantee for infant milk powder, which was specially developed for this category of pharmaceutical products, provided reassurance with a visible and authentic signature.

The Combishrink Babysafe equipment.

Quality cannot be improvised, it is a standard that accompanies the brand throughout the industrial and logistical processes, a contract of trust with consumers.

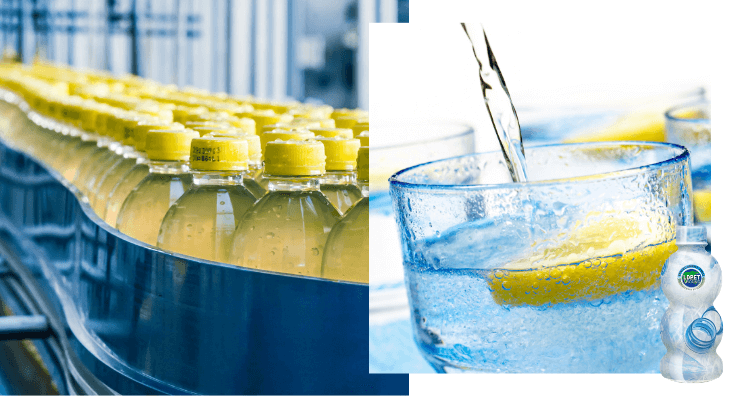

2015: awareness, technological change or simply the art of living

The major mineral water stakeholders chose LDPET® to ensure the enhanced recyclability of their PET bottles and their integration into the circular economy, without compromising the sensory identity of their products. Having won several awards, including a Packaging Trophy, an Excellence Technology Award and the AWA Environmental Contribution Award, LDPET® is used on the Combisteam LDPET, for optimal performance and controlled energy consumption.

2016: Iceclub® re-invents the consumption of sparkling wines in festive places

A new product, Iceclub®, which was developed for one of the most famous brands in the world of champagne, reproduced the immaculate appearance and freshness of ice to sign a cuvée intended for a new way of consumption: festive places.

The Combisteam machine FB 200 -AI300.

A world of excellence and daily expectations: no compromise is possible in the development of products for celebration and enjoyment.

2018: eco-design and 360° labeling, the food jar revolution

A breakthrough concept, the Combisteam DREAMONCUP®, which was co-developed with the company TECMA ARIES, offers sleeve labeling of multipack or unit containers, which are full, sealed, always clean, at high speed (600 cpm), with a sleeve introduction from the bottom of the container that was developed for the dairy products market

Dreamoncup participated in a world premiere in the sauce market in 2020: an iconic Brazilian brand is shaking up the codes, and switching from metal cans to a shaped plastic jar, to rejuvenate its image and offer eco-designed packaging. This packaging received several awards, including the "Premio ABRE de Embalagem Brasileira", and a "Grande Premios de Embalagems".