Decoration rhymes with eco-design for the still and sparkling wines markets

- A finishing solution for wines leaving the cellar

- A flexible technology that offers freedom of glass shapes and volumes

- A modular machine, built for medium and high production rates

- An eco-responsible offer to help you become carbon neutral

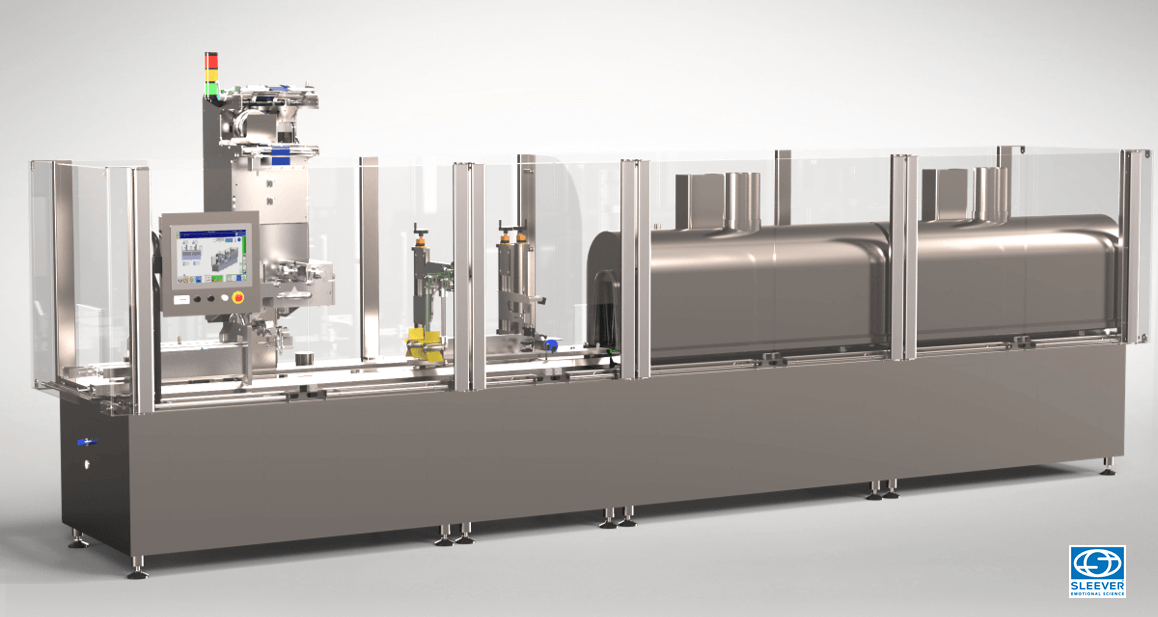

Features

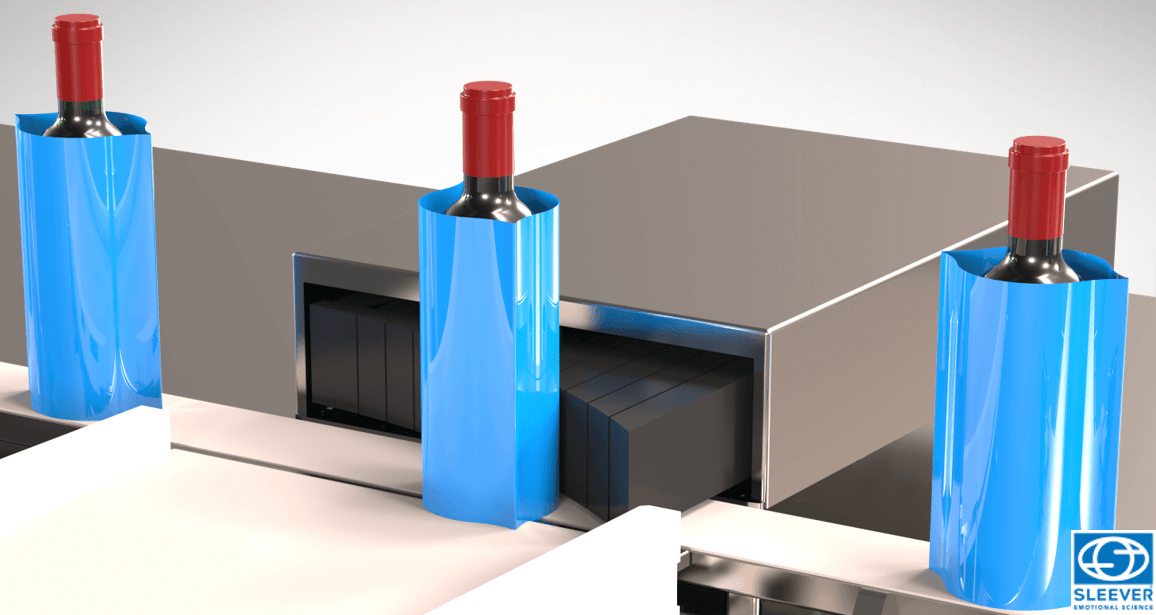

Cleanliness and finishing: a guarantee of quality for your wines

A machine built to meet the constraints of wine packaging, suitable for filled, corked and capped bottles coming out of the cellar. Units ensure that the bottles are clean and dry at the entrance and exit of the finishing process, in order to guarantee the quality of the finish.

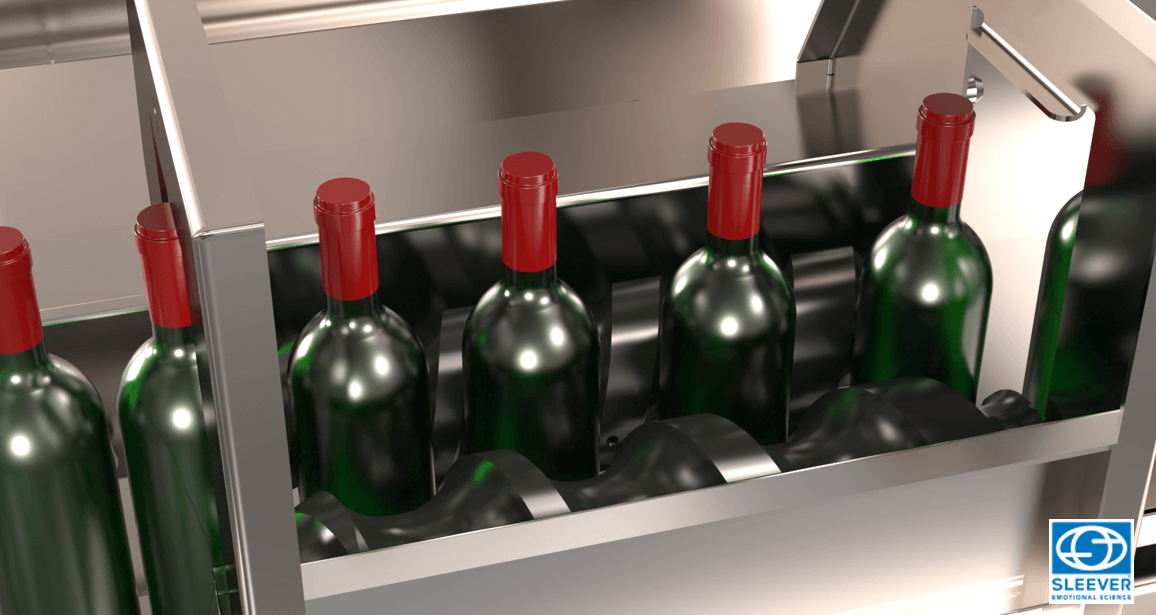

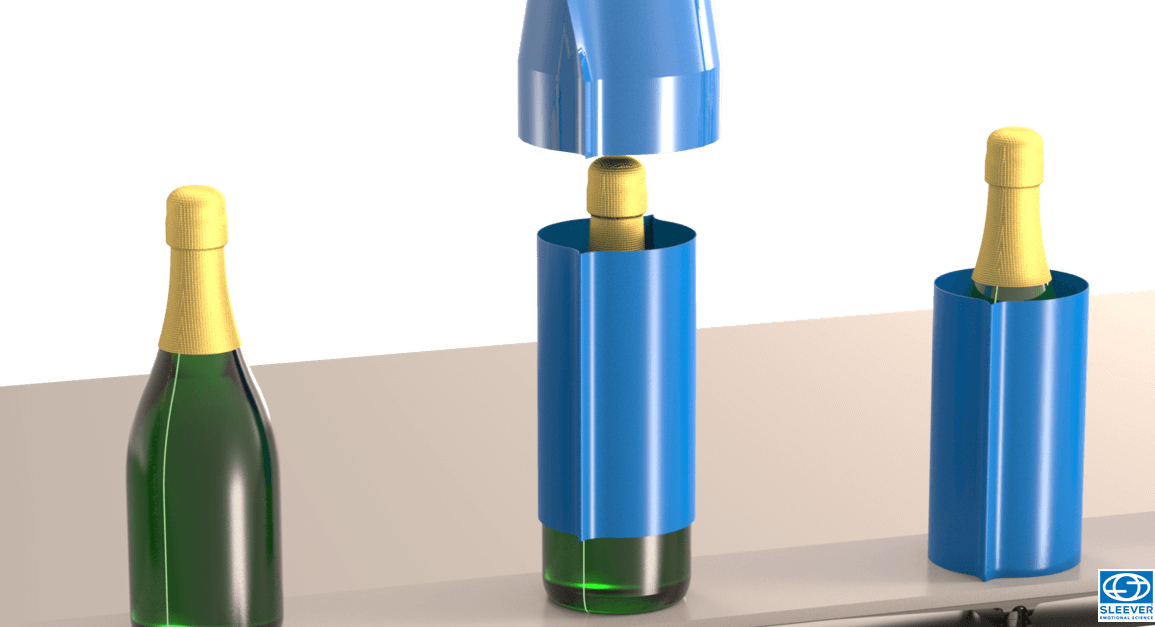

Format change flexibility: a priority for your productions

Take advantage of the maximum range of volumes, from 20cl to 1.5l, and the freedom of glass shapes, which represent your terroir and the maturation of your wines: Bordeaux, Burgundy, Alsace, Champagne, ...

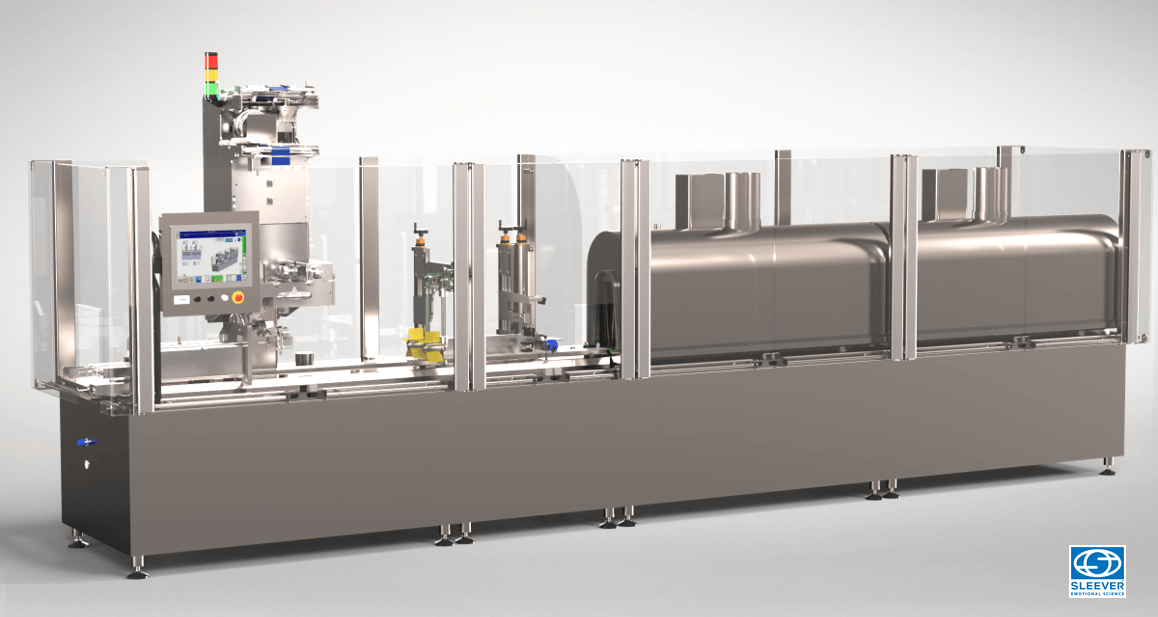

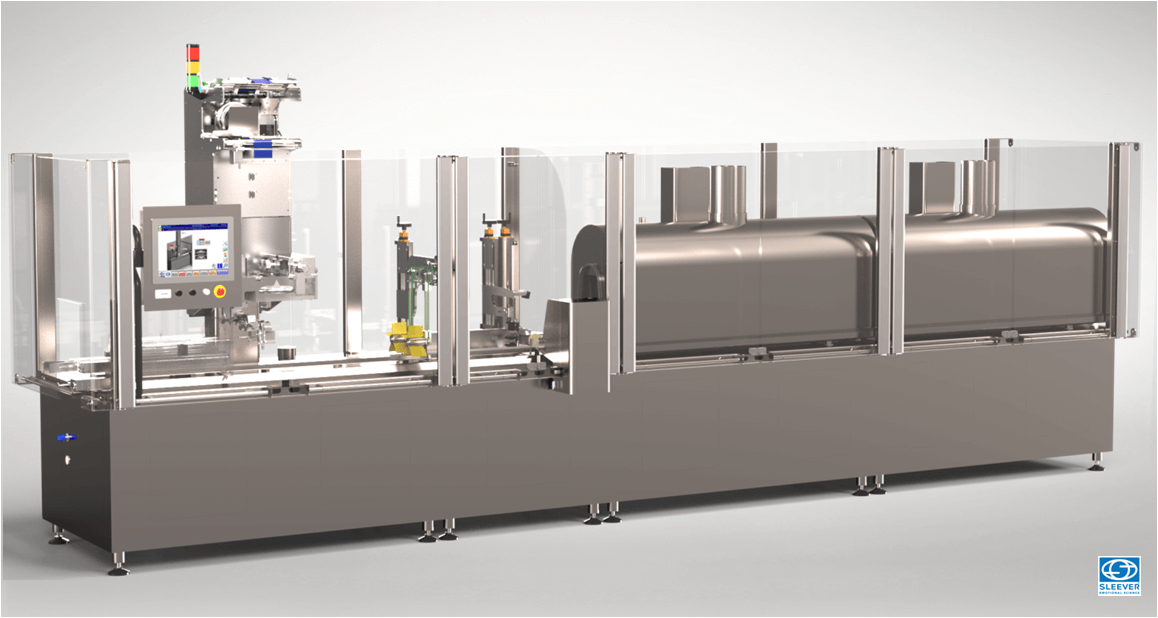

We have made modularity the secret of your performance

This compact, all stainless steel monobloc machine can be enhanced with different modules to meet your productivity needs, from 4,000 to 12,000 bottles/hour.

We strive for carbon neutrality with an eco-responsible offer

This machine has a unique and patented technology, equipped with a lifting ang lowering system. Its shrinkage chamber can be adapted to every format. We recycle part of our energy and minimize consumption.

Options

Your decor oriented to the glass parting line

Vision cameras combined with an orientation module ensure the correct positioning of the glassware before the sleeve application station. We take into account the specificities of your bottles (management of glass seam lines, embossing, reliefs, glass beads...).

A controlled checkpoint without accumulation

We have combined evolving control systems with cells and cameras to guarantee the quality of the product at the end of the packaging line. We have favored a progressive finger ejector combined with a non-accumulating conveyor to ensure the integrity of your bottles.

A quality finish with efficient drying

With a welded design, a fan system combined with adjustable nozzles provide a streak-free drying quality, which is adapted to every package size.

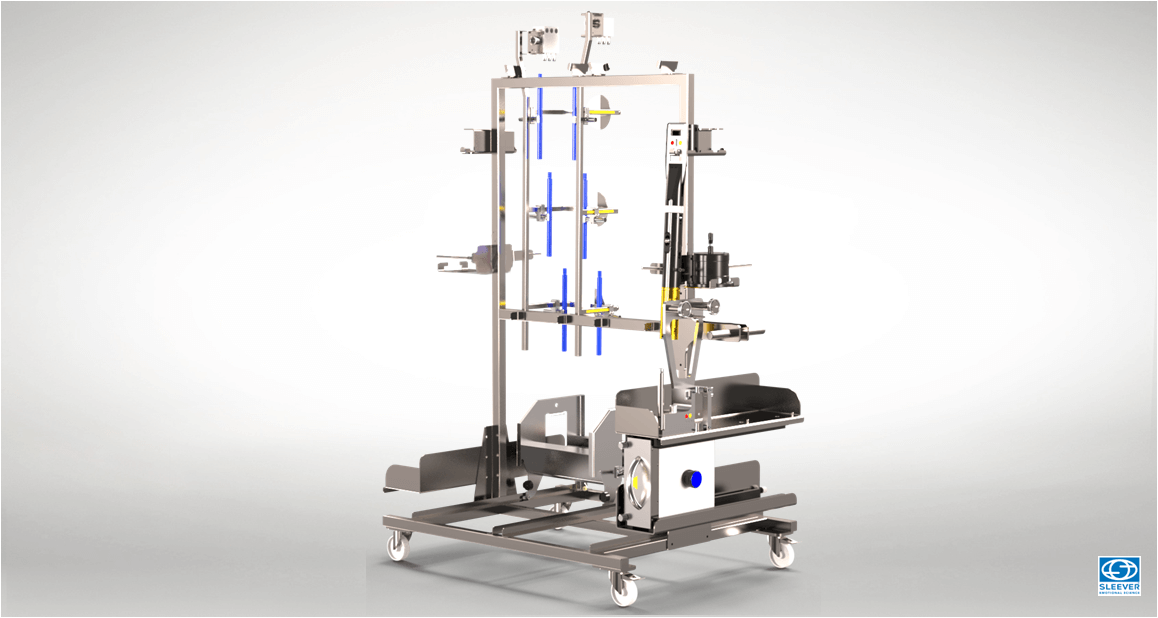

To optimize your format changeover times

The mobile tool trolley is designed to store your format sets. Mobile, and positionned neaby the machine, it offers a quick and easy access during your changeover operations.

Specifications

Machines

| Conveyor height | 980 mm +/- 50mm |

| Speed | From 50 to 200 bpm |

| Cutting diameter | From 30 to 100 mm |

| Steam consumption | 80 - 300 Kg/h |

| Steam pressure | 6 to 8 bars |

| Electrical consumption | 9 kW/h |

| Machine length | 6400 mm |

Packaging

| Materials | Glass |

| Shapes | Champagne, Bordeaux, Burgundy, complex shapes |

| Sizes | From 20cl to 1.5L |

| Products diameter | From 45 to 98mm |

| Products height | From 188 to 371 mm |

Sleeves

| Applications | Finishing, full body |

| Type of films | PET, RPET,... |

| Films thickness | From 40 to 90 microns |

| Finishing | Neutral, printed, special effects... |