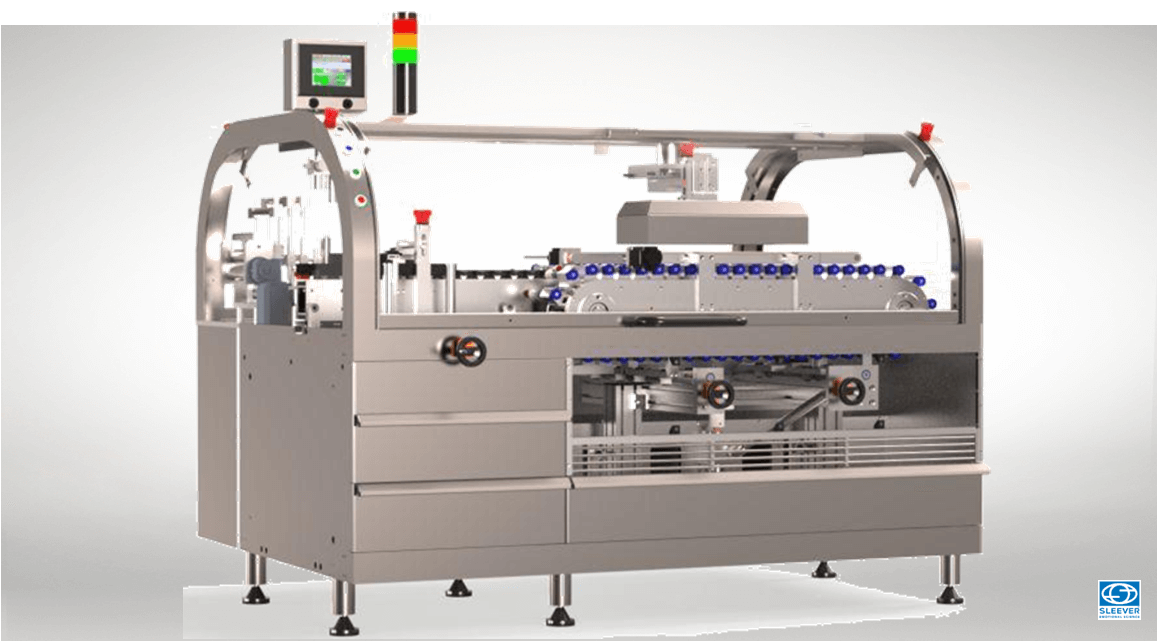

An innovative offer for full protection and personalization of small objects

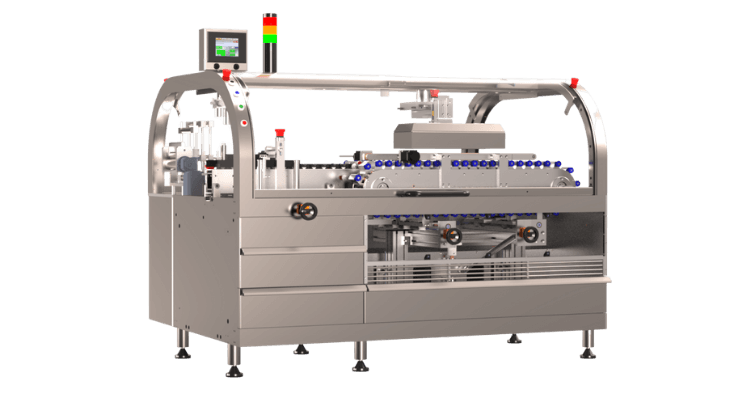

- A machine designed to handle unstable and/or hazardous products that require full protection

- An ultra-flexible machine that can handle a wide range of small household items (batteries, writing implements, tobacco, DIY)

- A high quality finish that provides protection without neglecting personalization.

- An interactive and connected machine that ensures performance

Features

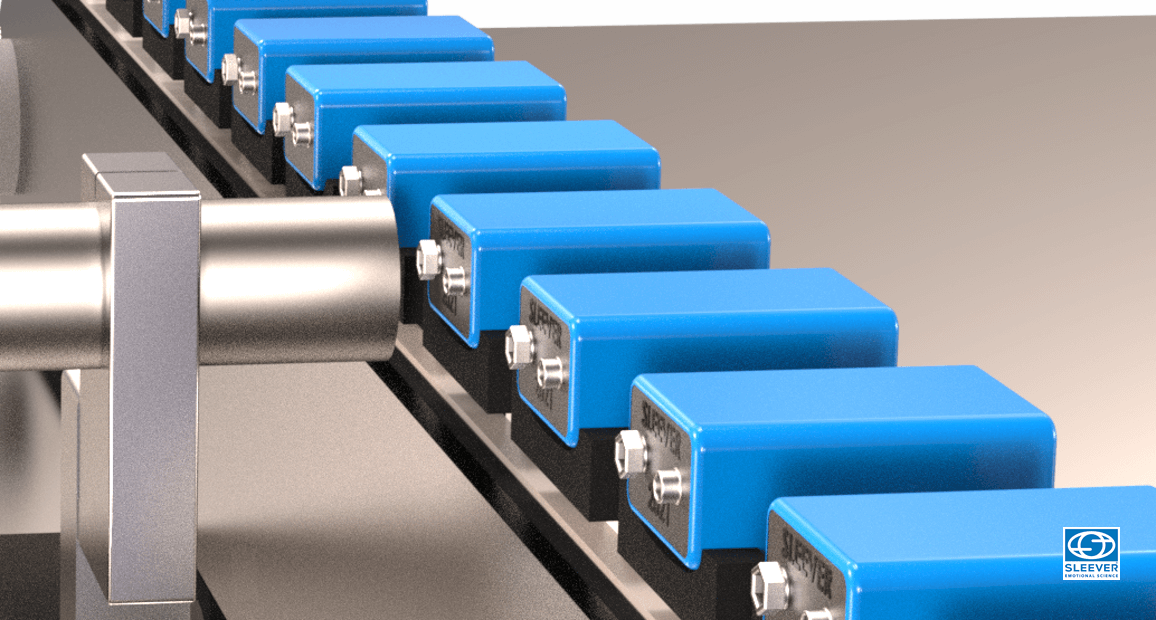

Ensure the full wrapping of products in specific formats

The design allows for the horizontal application of a tubular heat-shrink label on small, unstable products. The infrared/hot air shrink technology meets requirements and ensures full protection for certain sensitive products such as lithium batteries, particularly by preventing the risk of explosion.

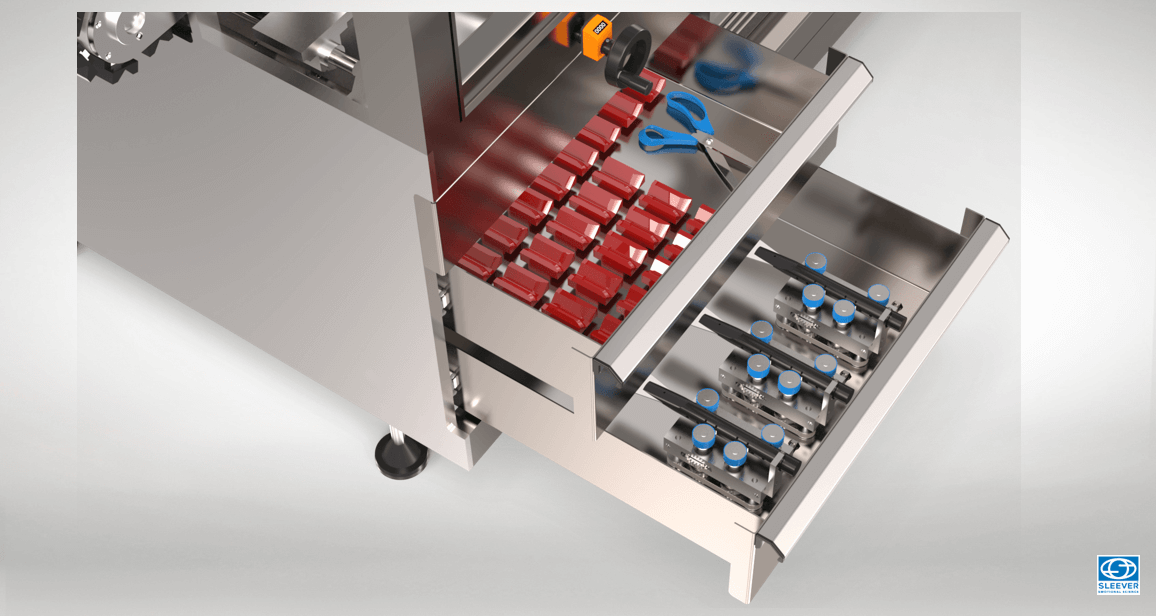

Your formats at your fingertips for greater flexibility

The ergonomic design and the flexibility of the machine make it possible to handle complex and varied shapes in a wide range of materials: round or square batteries, lighters, writing implements, household or do-it-yourself items... Format changes are simple and fast thanks to dedicated tools that are stored in the two drawers of the machine and are immediately accessible. Since the settings are stored in the interface, this operation only takes a few minutes, and the restart is immediate.

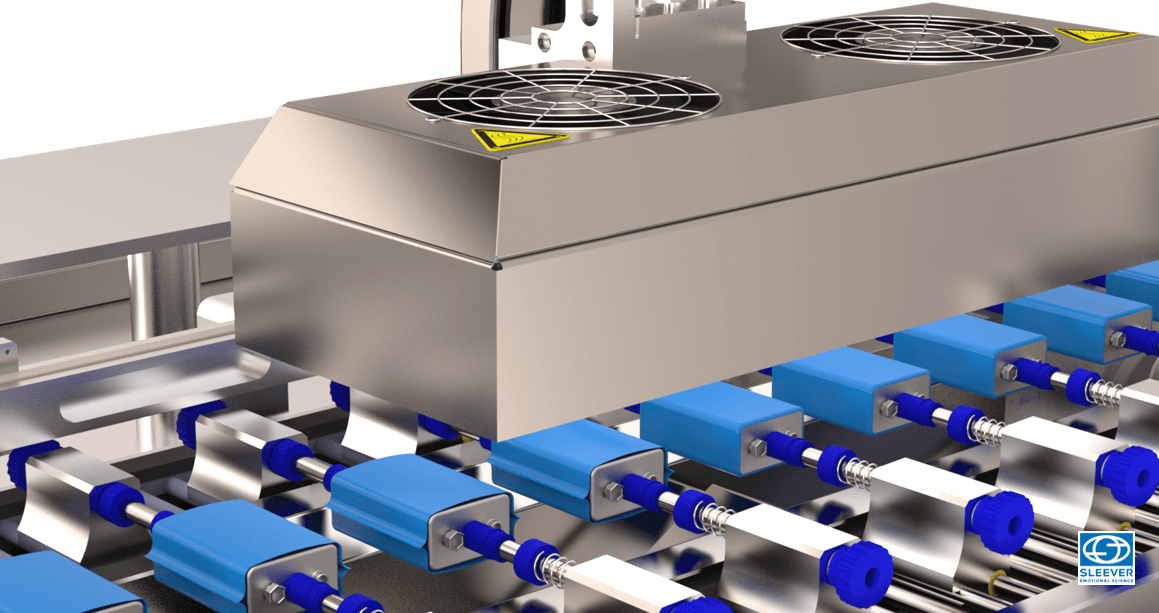

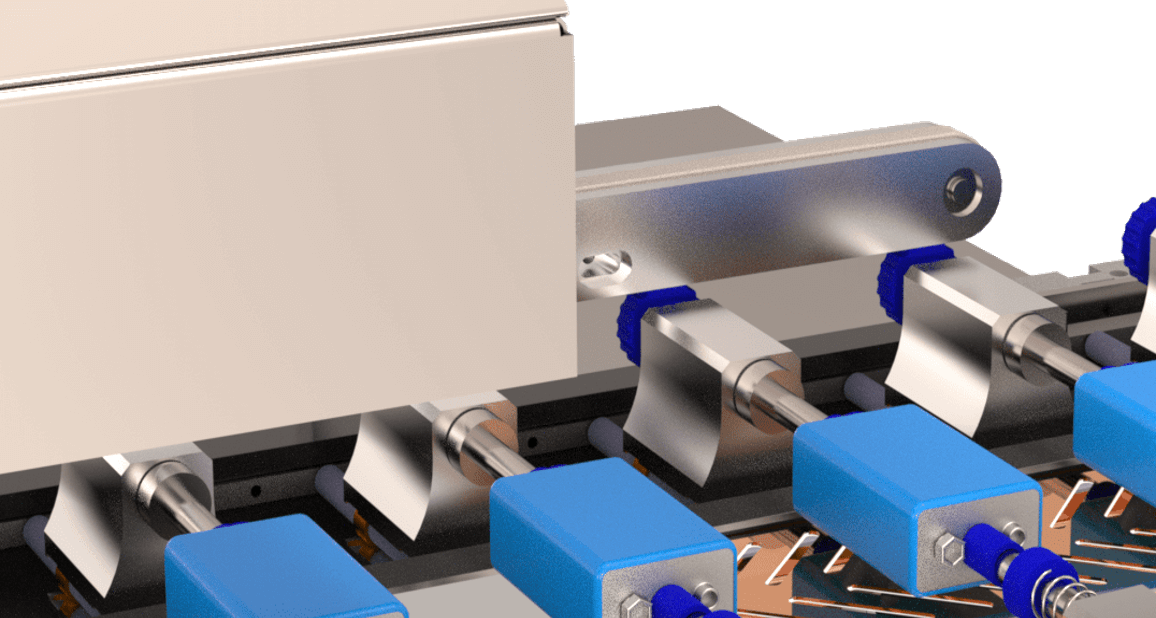

An adjustable shrinking technology adapted to sensitive products

The infrared hot air shrink technology of this machine allows you to adjust different settings, from the temperature to the product rotation speed for each format individually. All of these specific adjustments optimize the quality of the finish and reinforce the protection of sensitive products, such as lithium batteries, by avoiding any risk of contact and source of explosion.

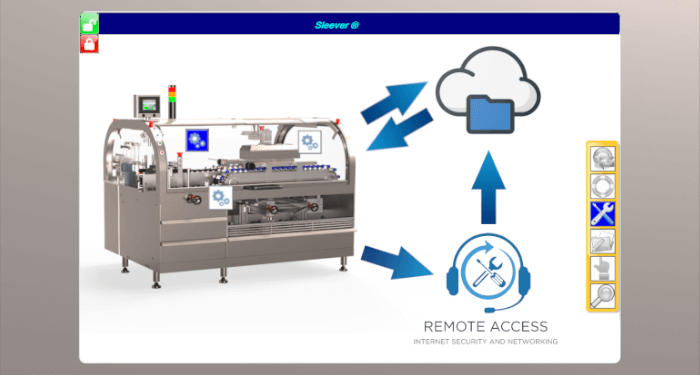

Interactivity for performance

Thanks to the data feedback from this interactive machine, the supervisor can continuously optimize the individual performance. Connected with other machines, upstream and downstream of the line, it also allows for the optimization of flows and the overall performance level of the line.

Options

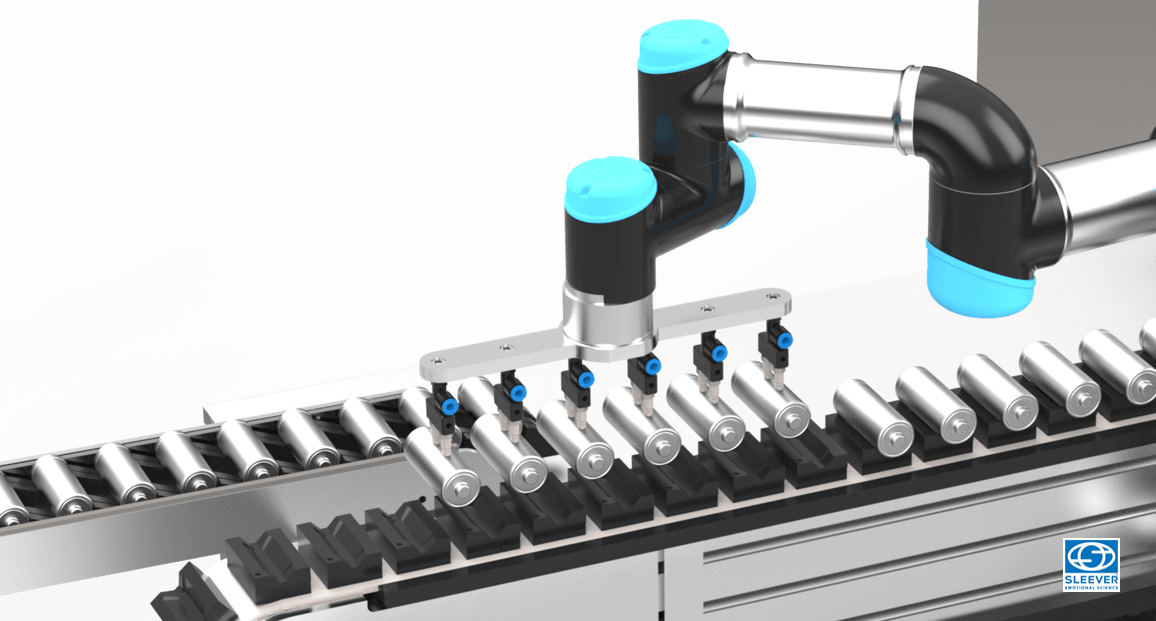

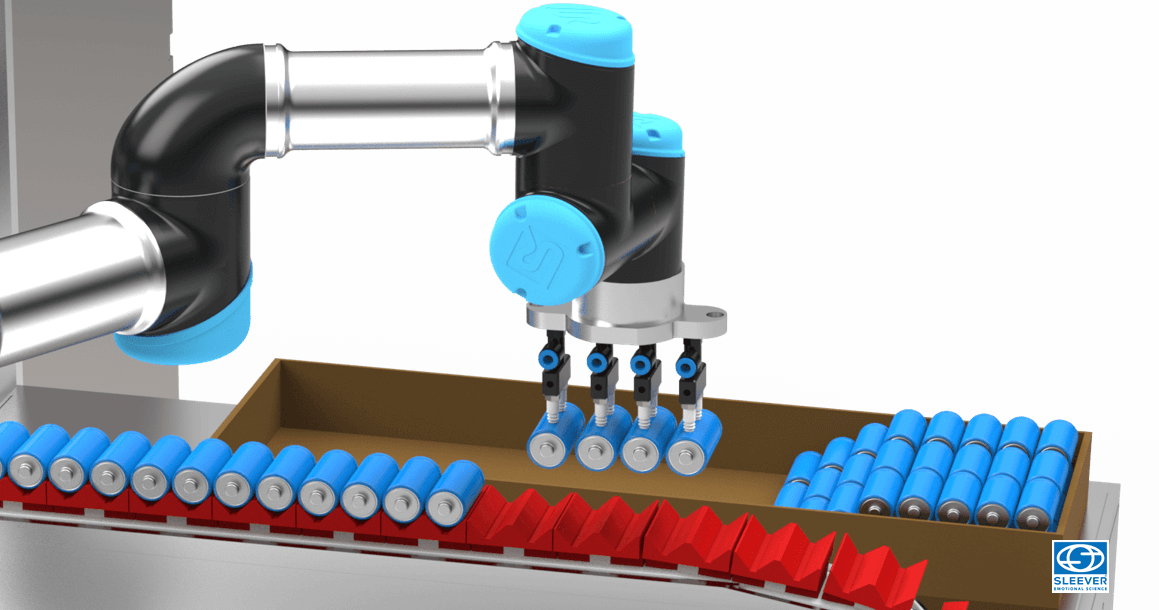

Automated loading for enhanced performance

A robotic module directly loads the products onto the conveyor and frees up an operator station assigned to this function. This solution improves performance over time and optimizes the operator's work.

A solution for the traceability and serialization of your products

Multiple solutions can ensure the traceability of your products and meet requirements and regulatory changes. Different printing technologies: laser, inkjet, thermal transfer... are available according to your specifications.

A quality finish: the assurance of reinforced protection

This module ensures the finish of an integral shrink-sleeve in the most difficult to reach places on products with complex shapes, and thanks to the quality of its finish, it ensures the full protection of the product.

A flexible and high-performance automation solution

The robot automatically unloads the product from the machine and frees up an operator station to optimize performance. It adapts to your specifications and line configuration, thus offering great flexibility of use.

Specifications

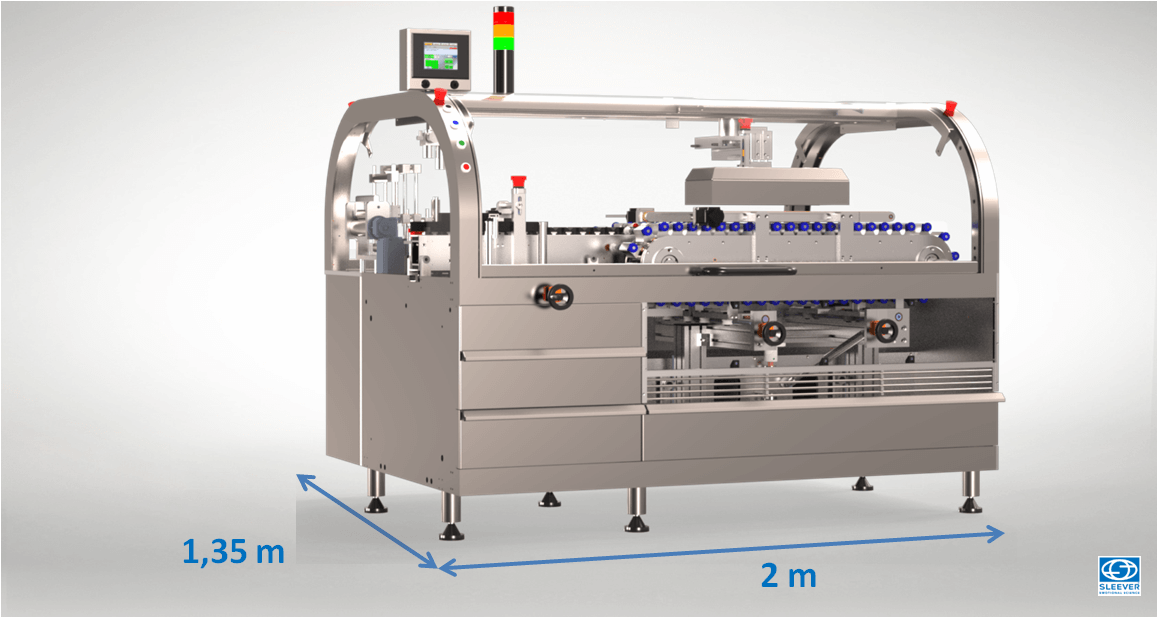

Machine

| Conveyor height | +/- 960 mm |

| Speed | 80 to 120 bpm |

| Compressed air | 6 bars |

| Electrical consumption | 10 to 15 KW/h |

| Machine length | 1900 mm |

Packaging

| Materials | PET, PP, Metal |

| Shapes | Cylindrical, square, special |

| Products diameter | 4 - 30 mm |

| Products length | 65 - 150 mm |

| Sizes | 3 - 100 ml |

Sleeves

| Applications | Full body |

| Type of film | PET, RPET, OPS |

| Film thickness | 30 to 60 microns |

| Finishing | Neutral , printed,... |