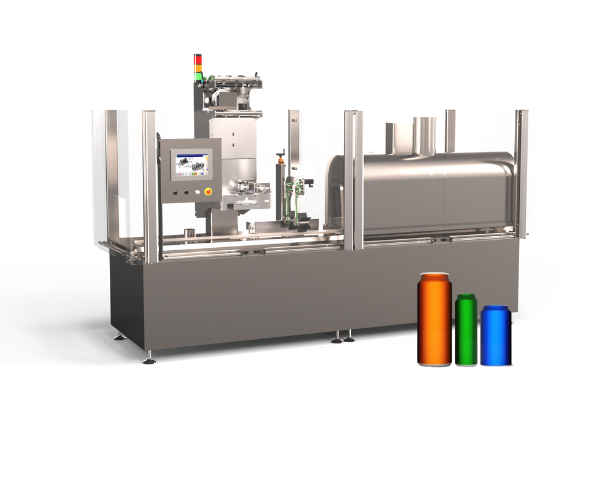

Can sleeving equipment offering the best recycling yield

- High reliability to meet brands, copackers and cofillers expectations

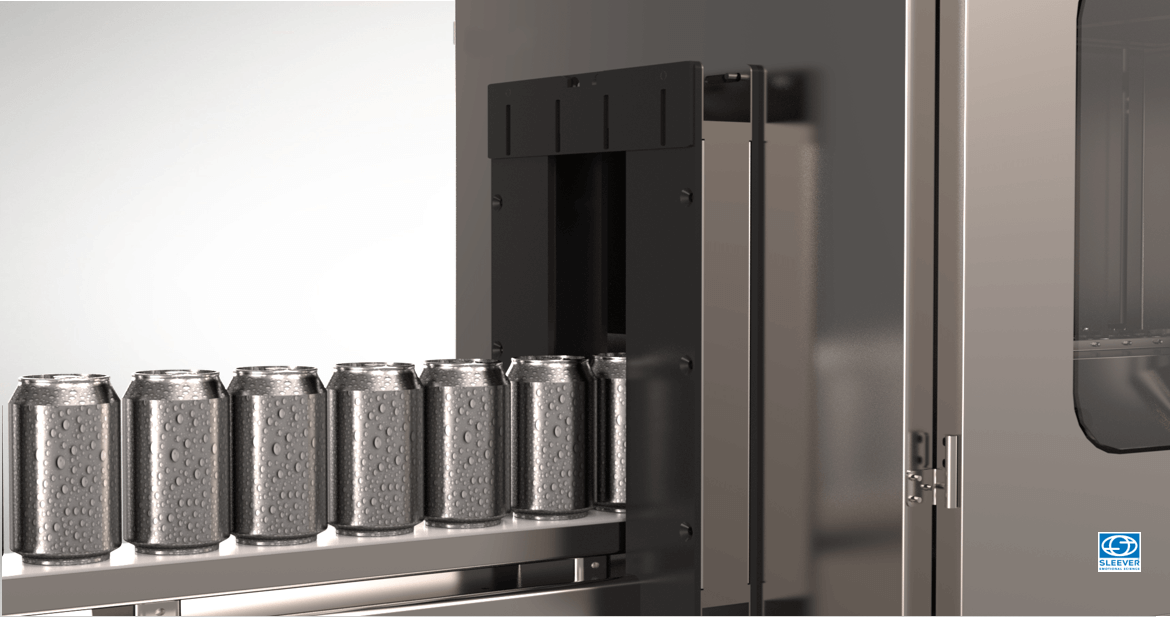

- Designed to operate with filled or empty cans

- Allowing the implementation of thin gauge films, for a better yield at recyclers

- An eco-designed shrinking tunnel to reduce energy consumption

Features

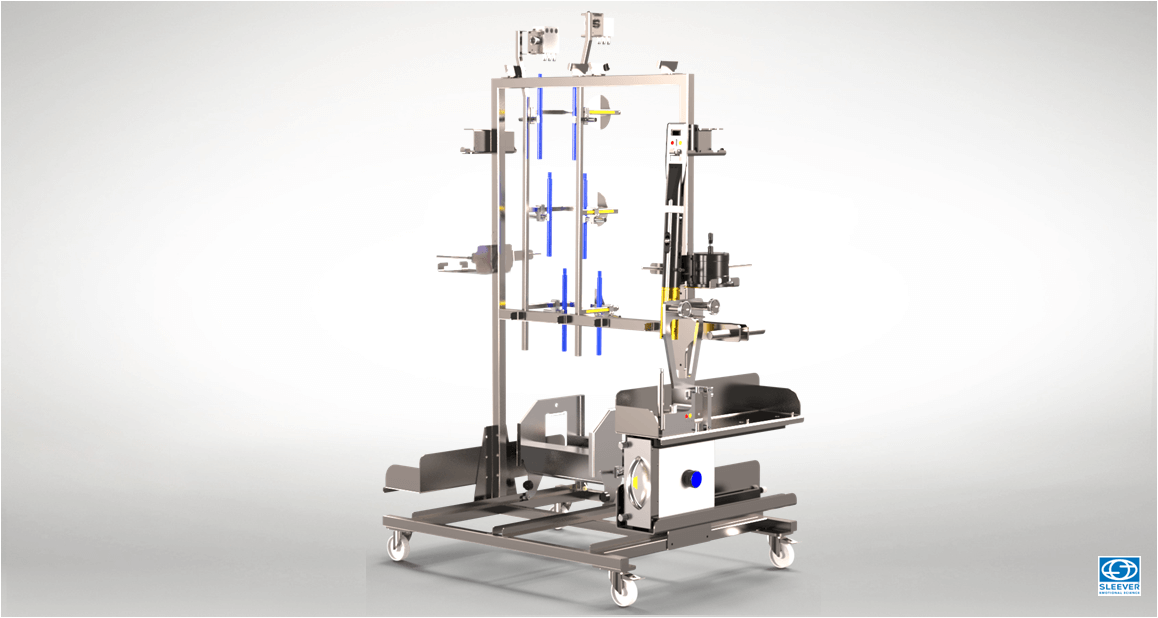

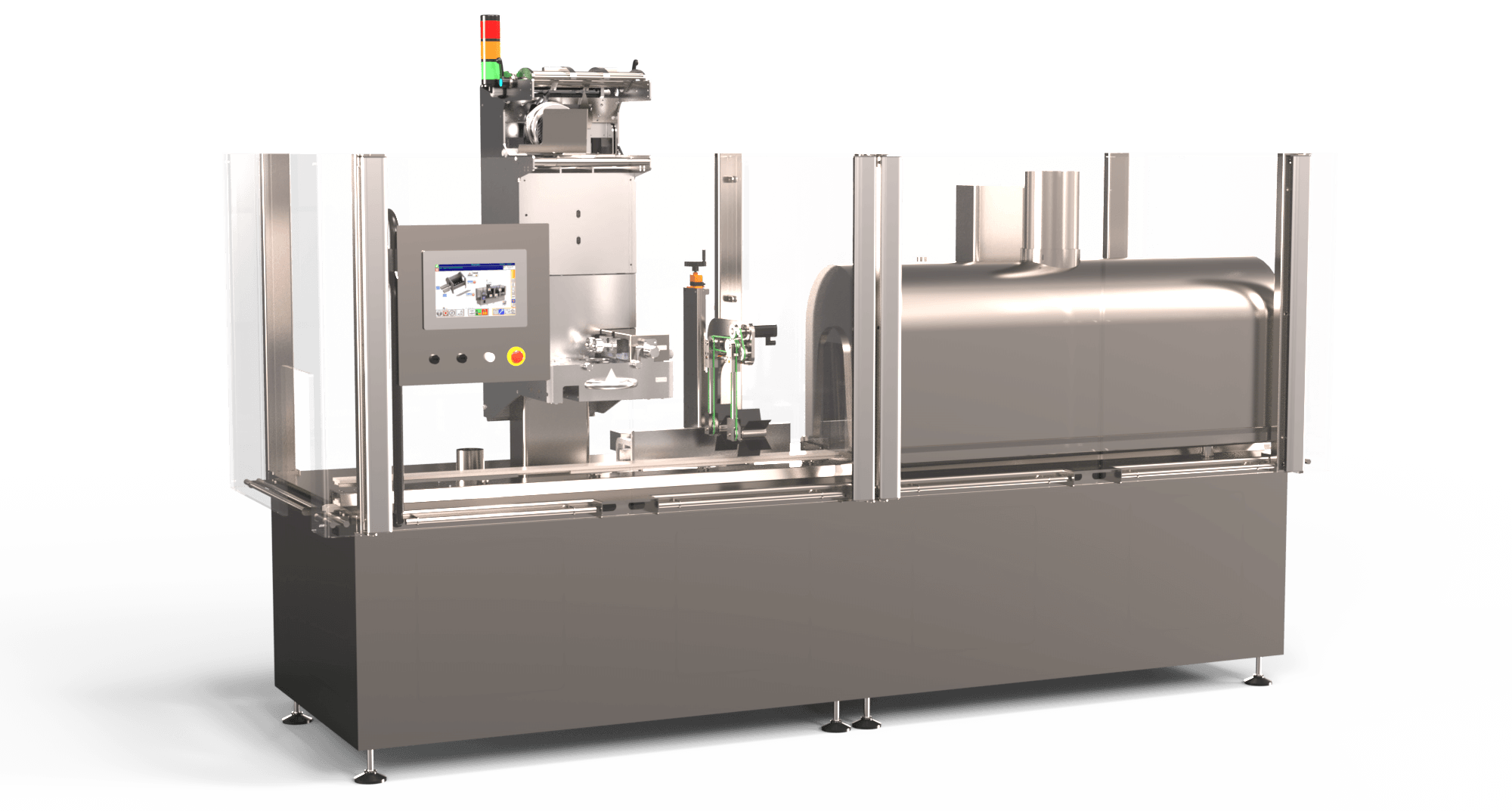

A monobloc and modular design to meet the can market expectations

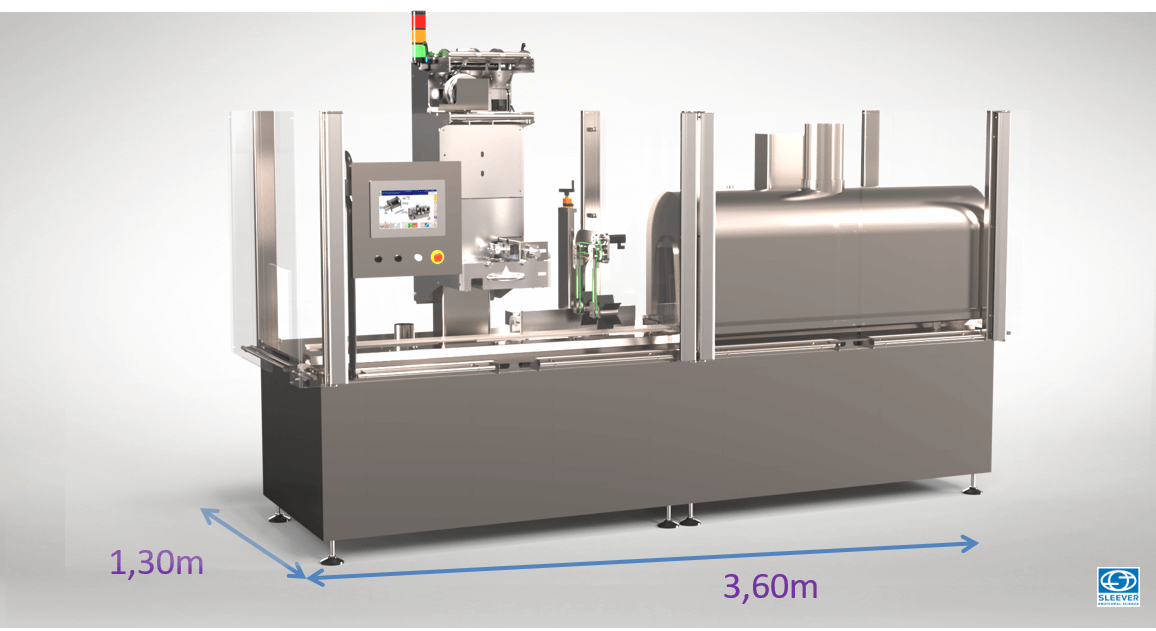

The monobloc design allows to integrate all the necessary modules to ensure high reliability. Brushless and automated adjustment are designed to meet high speed requirements. The unwinder unit is located outside the machine to not disturb the effectiveness of the process.

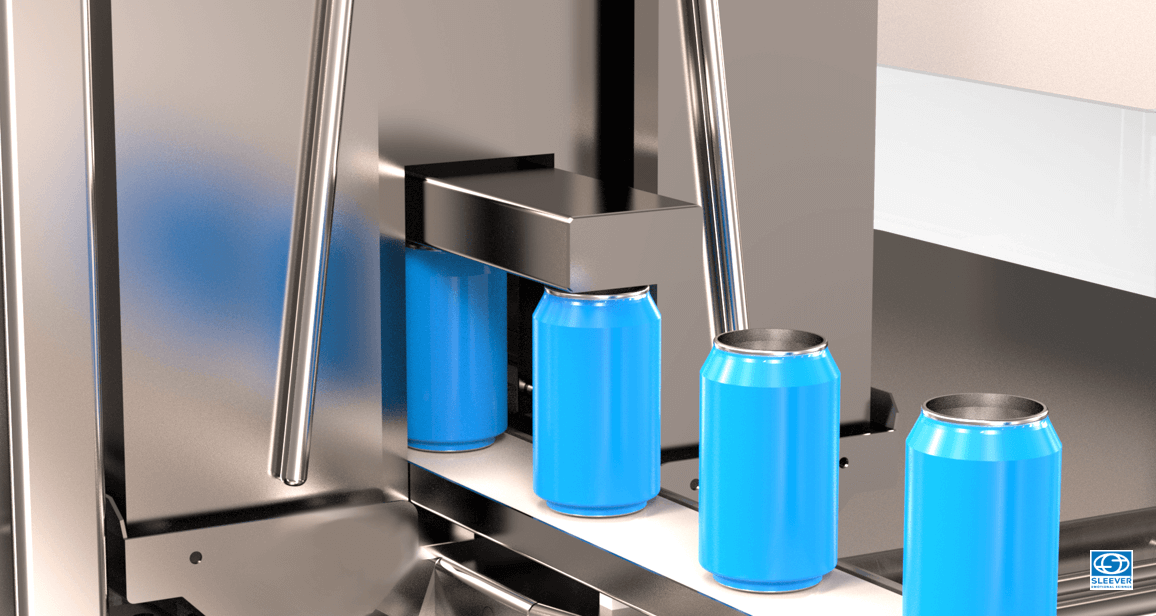

Offers the flexibility required by the can market

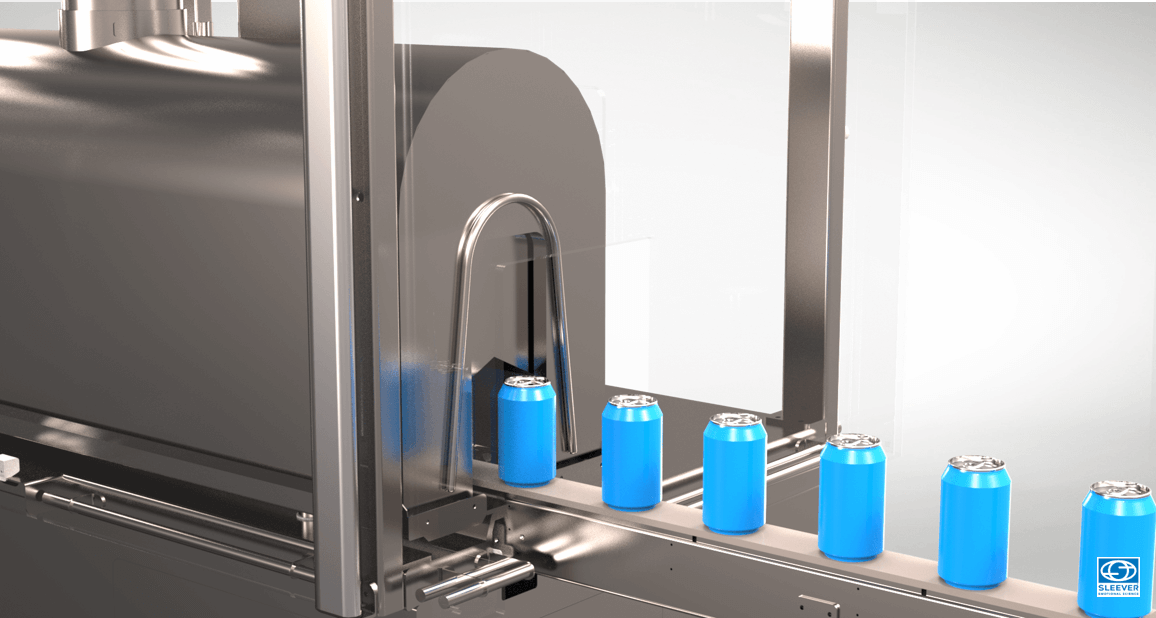

A modular design adapted to drive filled or empty cans,and to offer the required flexibility: different shapes (standard, slim, or complex shapes) and different contents from 8 to 24 oz. Change-overs are very quick from a format to another, and all specifications are saved in the HMI with a large user friendly touch screen panel.

Efficient implementation of thin-gauge films

To operate these new generation of films, we have developed a large capacity sleeve unwinder unit, designed to accommodate thin-gauge materials. Located outside the machine, it offers easy access to the reels.

An eco-designed tunnel to reduce energy consumption

This exclusive shrinking technology combines several systems: the expansion chamber, the height-adjustable tunnel and the steam diffusion system adjusted to each product. This results in an eco designed shrinking tunnel optimizing your energy consumption for all formats.

Options

Can filling combined with an efficient labelling solution

A watertight structure with a stainless steel frame to withstand humid working conditions, the equipment can be combined with dryers at the infeed and outefeed of the machine to reduce the presence of traces of moisture on the products to be sleeved.

Reduce your format changeover times with the tool tolley

An ergonomic mobile tool trolley , which is light to move, ready for operators, specially designed to store tools and keep them available next to the machine to reduce downtime during format changes. The tools are protected when not in use and when being moved.

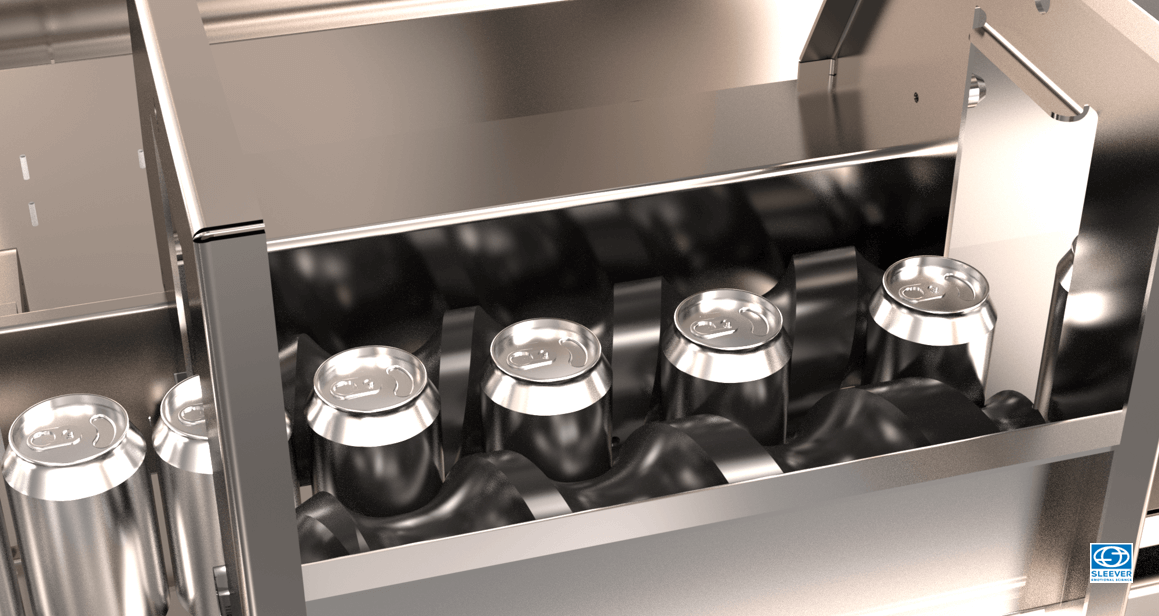

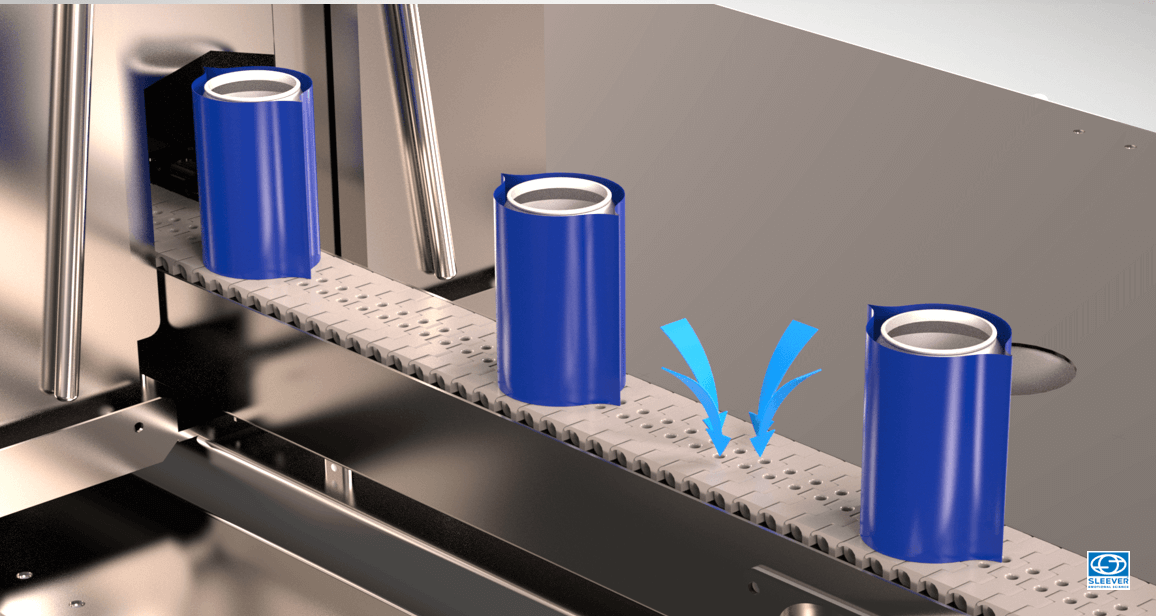

Empty cans management

Vacuum conveyor help to manage empty cans at high speed to maintain the can in standing up position and guarantee the reliability of the different steps during all the process.

Guarantee for empty cans to have no water drop before filling

This module located in the shrinking tunnel guarantee to have no water drop falling inside the can before filling.

This competitive module provide further savings by avoiding to have a return module in input and output of the machine, to optimize cost and efficiency with drying cans in output.

Specifications

Machines

| Conveyor height | 980 +/- 50 mm |

| Speed | 200 bpm |

| Cutting diameter | 100 mm |

| Steam consumption | 90 kg/h |

| Steam pressure | 6-8 bars |

| electrical consumption | 12 kW/h |

| Machine length | 3600 mm |

Packaging

| Material | Metal |

| Shapes | Cylindrical, slim, complex shapes... |

| Product diamter | 50 - 70 mm |

| Product height | 88 - 170 mm |

| Sizes | 15 cl - 75 cl |

Sleeves

| Applications | Full body |

| Films | PET, RPET |

| Film thickness | 20 - 50 microns |